Honeywell AutoCube 8200 vs NTEP Certified Scales with Integrated Dimensioning

In today’s logistics industry, the demand for efficient and reliable dimensioning and weighing equipment has never been greater. With the e-commerce sector experiencing exponential growth, businesses strive to ensure their inventory meets shipping standards without incurring unnecessary costs. Among the top solutions available are the Honeywell AutoCube 8200 and NTEP certified scales with integrated dimensioning. Each offers a unique set of features and benefits tailored to different business needs.

Understanding the Need for Dimensioning and Weighing in Logistics

Accurate dimensioning and weighing are critical in the logistics industry to ensure packages comply with shipping requirements. Precise measurements help businesses avoid overpaying for shipping fees and reduce the risk of damages during transit. According to a Statista report, global e-commerce sales are projected to reach $8.1 trillion by 2026, underscoring the importance of efficient logistics solutions.

Beyond cost savings, accurate dimensioning and weighing optimize warehouse space and inventory management. By knowing the exact dimensions and weight of packages, businesses can organize their inventory more effectively, reducing storage costs and enhancing overall warehouse productivity.

Advancements in technology have led to the development of automated systems that swiftly and accurately measure packages. These systems not only reduce manual labor but also minimize human error, enhancing operational efficiency and ensuring timely deliveries.

What are AutoCube 8200 and NTEP Certified Scales?

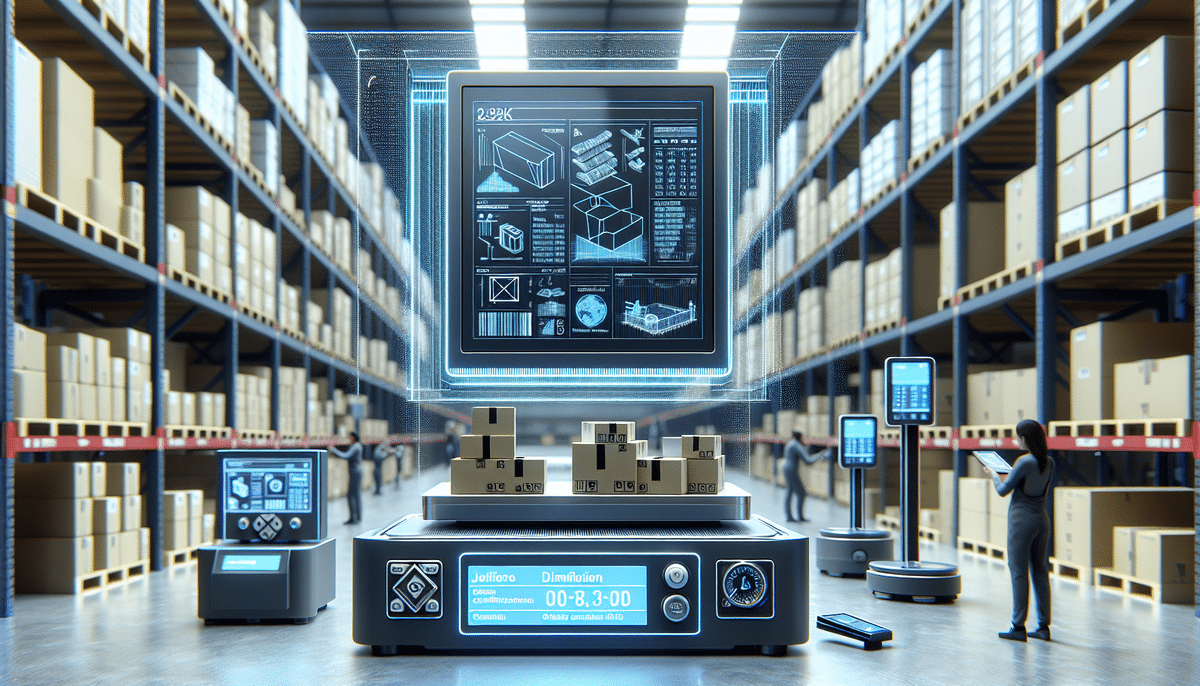

The Honeywell AutoCube 8200 is a sophisticated dimensioning system that employs 3D depth sensing technology to accurately measure and weigh packages. It features automated data capture, real-time dimensioning, and enhanced efficiency, making it a preferred choice for many businesses.

On the other hand, NTEP certified scales with integrated dimensioning combine traditional weighing scales with advanced dimensioning technology. These scales are certified by the National Type Evaluation Program (NTEP), ensuring their accuracy and reliability for commercial applications.

Both solutions are indispensable for businesses requiring precise package measurements. They streamline operations, reduce errors, and enhance customer satisfaction, especially in the booming e-commerce landscape. Investing in these technologies can lead to significant savings and improved profitability.

Comparative Analysis of Honeywell AutoCube 8200 and NTEP Certified Scales

When deciding between the AutoCube 8200 and NTEP certified scales, it's essential to evaluate their distinct features and advantages:

- AutoCube 8200: Measures packages from any orientation, offers real-time dimensioning, automated data capture, and significantly boosts efficiency and accuracy.

- NTEP Certified Scales: Ideal for businesses with existing scales, allowing easy integration of dimensioning capabilities. Their NTEP certification guarantees high precision and reliability, making them suitable for high-accuracy requirements.

Cost is another pivotal factor. The AutoCube 8200 tends to be pricier due to its comprehensive feature set, while NTEP certified scales offer a more cost-effective solution for businesses seeking reliable dimensioning without extensive additional investment. The optimal choice hinges on your business's specific needs and budget constraints.

Key Features and Benefits of AutoCube 8200

The Honeywell AutoCube 8200 stands out with several key features:

- Real-Time Dimensioning: Provides immediate and highly accurate measurements.

- Automated Data Capture: Streamlines the measurement process, reducing manual input.

- Versatile Package Support: Handles a wide range of package sizes and shapes.

- Enhanced Efficiency: Optimizes workflows, increases throughput, and minimizes operator fatigue.

Additionally, the AutoCube 8200 boasts a user-friendly interface, facilitating seamless integration with existing warehouse management systems. Its durable construction ensures longevity and reliability in demanding warehouse environments.

Key Features and Benefits of NTEP Certified Scales

NTEP certified scales offer a robust set of features:

- High Precision: NTEP certification ensures top-tier accuracy and reliability.

- Easy Integration: Compatible with existing scales, adding dimensioning functionality effortlessly.

- Wide Package Support: Accommodates various package sizes and shapes with ease.

- Legal-for-Trade: Compliance with local and national regulations guarantees trustworthy measurements.

- Advanced Software: Features like data tracking and analysis enhance operational efficiency.

Designed to withstand harsh industrial conditions, these scales are built with durable materials, ensuring consistent performance even in challenging environments.

Which One is More Accurate? AutoCube 8200 or NTEP Certified Scales?

Both the AutoCube 8200 and NTEP certified scales deliver exceptional accuracy. The AutoCube 8200 leverages 3D depth sensing technology, while NTEP scales are rigorously tested and certified for precision by the National Type Evaluation Program. To determine which is more suitable, consider the specific requirements of your applications:

- AutoCube 8200: Ideal for measuring irregularly shaped objects with high precision.

- NTEP Certified Scales: Best suited for weighing larger, uniform items where compliance with legal standards is paramount.

For definitive accuracy comparisons, consulting the manufacturer’s documentation or conducting in-house tests is recommended.

Which One is More Suitable for Your Business Needs? AutoCube 8200 or NTEP Certified Scales?

Choosing the right solution depends on various factors:

- Package Size and Shape: If your business handles diverse package shapes and sizes, the AutoCube 8200 offers greater flexibility.

- Existing Infrastructure: Businesses with established scaling systems may find it cost-effective to integrate NTEP certified scales.

- Level of Automation: The fully automated AutoCube 8200 reduces labor costs and increases throughput, suitable for high-volume operations.

- Budget Constraints: NTEP certified scales present a more budget-friendly option without compromising on accuracy.

Moreover, the AutoCube 8200’s advanced features like barcode scanning and seamless warehouse management system integration make it a comprehensive solution for businesses seeking end-to-end package measurement and tracking.

Cost Comparison: Honeywell AutoCube 8200 vs NTEP Certified Scales with Integrated Dimensioning

The investment in the Honeywell AutoCube 8200 is generally higher compared to NTEP certified scales. However, the AutoCube 8200 offers a more extensive range of features that can lead to significant long-term savings by enhancing measurement speed and accuracy, thereby reducing errors and manual labor costs. In contrast, NTEP certified scales provide a cost-effective solution for accurate dimensioning without the need for a complete system overhaul.

Businesses must weigh the initial costs against potential savings and operational benefits. According to a Forbes analysis, investing in advanced dimensioning solutions can improve overall efficiency by up to 30%, offering a substantial return on investment over time.

Customer Reviews and Satisfaction Rates for Honeywell AutoCube 8200 and NTEP Certified Scales

Feedback from users indicates high satisfaction levels with both solutions. A Honeywell survey revealed that 97% of AutoCube 8200 users appreciate its performance and feature set. Customers highlight its accuracy, ease of use, and reliability as key strengths.

Similarly, NTEP certified scales have garnered positive reviews for their precision and compliance with industry standards. Businesses value the assurance that comes with legal-for-trade certification, ensuring that measurements meet regulatory requirements.

Industry recognition further underscores their quality. The AutoCube 8200 received the prestigious Red Dot Design Award in 2019 for its innovative design, while NTEP certified scales are esteemed for their adherence to national standards, as outlined by the National Institute of Standards and Technology (NIST).

The Future of Dimensioning and Weighing Technology in the Logistics Industry

As e-commerce continues to grow, the logistics sector will increasingly rely on advanced dimensioning and weighing technologies. Future developments are expected to incorporate artificial intelligence (AI) and machine learning to enhance measurement accuracy and speed. These technologies can analyze vast datasets to optimize operations, reduce errors, and foresee trends.

Additionally, the rise of mobile dimensioning and weighing solutions will provide greater flexibility, allowing businesses to integrate real-time data into their logistics systems seamlessly. These innovations will enable more responsive and adaptive supply chain management, essential for meeting evolving market demands.

For more insights into future trends, refer to the McKinsey & Company report on the future of logistics.

Choosing the Right Dimensioning and Weighing Solution for Your Business

Selecting the optimal dimensioning and weighing solution involves assessing your business’s unique needs:

- Operational Requirements: Determine the volume and variety of packages you handle.

- Integration Capabilities: Ensure the solution can seamlessly integrate with your existing systems.

- Budget Considerations: Balance initial costs with long-term benefits and savings.

- Accuracy and Compliance: Verify that the solution meets necessary accuracy standards and regulatory compliance.

By carefully evaluating these factors, businesses can select a solution that not only meets current demands but also scales with future growth.

Conclusion: Honeywell AutoCube 8200 vs NTEP Certified Scales - Which One is the Winner?

Both the Honeywell AutoCube 8200 and NTEP certified scales offer exceptional benefits tailored to different business needs. The AutoCube 8200 excels as a stand-alone, fully automated solution suitable for diverse and high-volume operations, while NTEP certified scales provide a cost-effective, highly accurate option ideal for businesses integrating dimensioning into existing systems.

The "winner" ultimately depends on your specific business requirements, budget, and operational workflow. Assessing these factors will guide you in selecting the solution that best aligns with your logistics and shipping objectives.