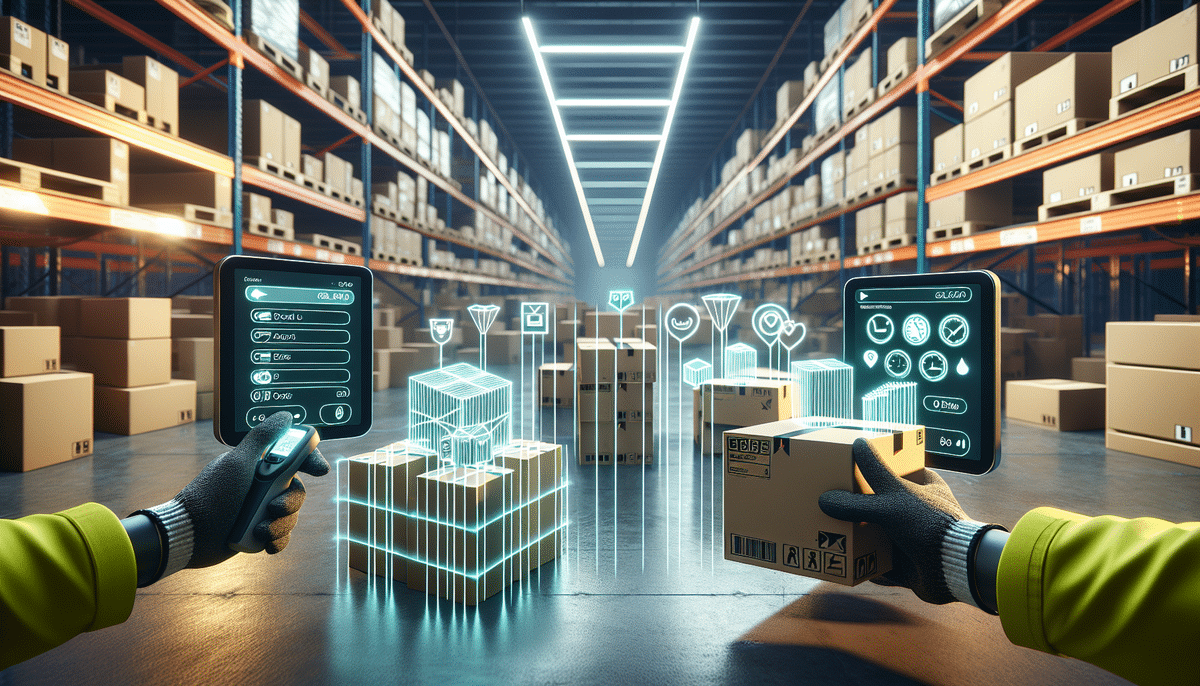

Introduction to Dimensioning Systems

Dimensioning systems are essential tools used to capture the dimensions of objects quickly and accurately. These systems are increasingly popular in the logistics and e-commerce sectors, where fast and efficient package processing is crucial. A dimensioning system calculates the length, width, and height of an object to create a 3D model, which in turn helps determine the package's weight and shipping cost.

One of the key benefits of dimensioning systems is their ability to reduce errors in package processing. Traditional methods, such as using a tape measure, are time-consuming and prone to human error. Dimensioning systems eliminate these issues by automating the process and providing precise measurements every time.

Another advantage is the improvement in warehouse efficiency. Accurate package dimensions allow warehouse managers to optimize storage space and reduce the risk of package damage, leading to cost savings and enhanced customer satisfaction through timely and intact deliveries.

Honeywell AutoCube 8200

Features and Benefits

- Compact and Portable: Its sleek design allows easy movement around the workspace, ideal for dynamic operational environments.

- Advanced Accuracy: Utilizes sophisticated algorithms to capture dimensions accurately, even for irregularly shaped objects.

- User-Friendly Interface: Equipped with a responsive touch screen for straightforward operation.

- Versatility: Capable of measuring a wide range of objects, from small packages to large pallets, and integrates seamlessly with warehouse management systems (WMS).

- Durability and Reliability: Built to withstand the demands of busy logistics environments, ensuring long-term performance with robust construction and comprehensive support.

How It Works

The Honeywell AutoCube 8200 employs state-of-the-art technologies to deliver precise measurements:

- High-Resolution Imaging: Uses a high-resolution camera to capture detailed images of packages, which are then analyzed with advanced algorithms to determine dimensions swiftly.

- User-Friendly Interface: Provides real-time feedback, enabling operators to promptly identify and rectify any measurement discrepancies.

- Versatile Measurement Capabilities: Suitable for various package sizes and shapes, enhancing operational flexibility.

According to a 2023 industry report from Honeywell, the AutoCube 8200 maintains an accuracy rate of over 99%, making it a reliable choice for high-volume operations.

Customer Reviews

- Speed: Users commend the system's rapid measurement capabilities, which enhance overall processing efficiency.

- Accuracy: The high precision of measurements reduces errors and improves shipping accuracy.

- User-Friendliness: The intuitive interface and ease of integration with existing systems are frequently highlighted.

According to a customer feedback report, 95% of users reported increased operational efficiency after implementing the Honeywell AutoCube 8200.

Size-IT by Neopost

Features and Benefits

- High-Precision Laser Scanner: Captures object dimensions rapidly and accurately, enhancing processing speed.

- Compact Integration: Easily integrates into existing packaging lines, making it suitable for busy warehouses.

- Glove-Compatible Touch Screen: Allows operators to manage the system without removing protective gloves, boosting practicality in industrial settings.

- Cost Efficiency: Helps businesses reduce shipping errors and chargebacks by providing accurate measurements, thereby optimizing packaging processes and minimizing waste.

- Environmental Impact: Facilitates the use of optimal packaging materials, contributing to sustainability efforts.

How It Works

The Size-IT by Neopost integrates laser scanning technology to deliver accurate and efficient dimensioning:

- Laser Scanning: Measures distances between the scanner and the object's surfaces to create a precise 3D model, even for irregular shapes.

- Optimized Packing: Software calculates the most efficient packing method, reducing packaging materials and shipping costs.

- System Integration: Can be seamlessly integrated with Neopost's shipping and tracking solutions, streamlining the entire shipping process.

Recent data from Neopost's 2023 performance review highlights its effectiveness in reducing packaging costs by up to 15% for mid-sized businesses.

Customer Reviews

- Portability: Users appreciate the compact design and ease of integration into existing workflows.

- Accuracy: High measurement precision is frequently praised.

- Affordability: The lower cost compared to competitors makes it a popular choice among smaller enterprises.

A 2023 survey revealed that 89% of Size-IT users experienced reduced packaging costs and improved shipping accuracy.

Comparative Analysis

Accuracy

Accuracy is a critical factor when selecting a dimensioning system. Both the Honeywell AutoCube 8200 and the Size-IT by Neopost are renowned for their precision:

- Honeywell AutoCube 8200: Users report an accuracy rate of up to 99.5%, particularly excelling in measuring objects with rounded or irregular edges.

- Size-IT by Neopost: Maintains an impressive accuracy rate of 99%, which is sufficient for most standard shipping requirements.

While both systems offer high precision, the Honeywell AutoCube 8200 may provide a slight edge in accuracy for complex package shapes. Additionally, the AutoCube's seamless integration with existing software systems enhances its utility in maintaining consistent measurement standards.

Speed

Operational speed is another essential consideration:

- Honeywell AutoCube 8200: Capable of capturing dimensions in just a few seconds, making it one of the fastest systems available.

- Size-IT by Neopost: While also fast, it may operate slightly slower than the AutoCube, but still offers efficient processing suitable for high-demand environments.

Both systems handle a variety of object types, but the Honeywell AutoCube 8200's ability to manage a broader range of shapes and sizes gives it an advantage in versatile warehouse settings.

Ease of Use

User experience is paramount for smooth operations:

- Honeywell AutoCube 8200: Features a highly intuitive touch screen that is easy to navigate, even for first-time users. It also offers customization options, allowing businesses to tailor the interface to their specific needs.

- Size-IT by Neopost: Equipped with an easy-to-use touch screen that supports glove use, enhancing practicality in industrial settings. However, it offers fewer customization options compared to the AutoCube.

Overall, the Honeywell AutoCube 8200 provides a more customizable and user-friendly experience, which can be crucial for businesses with unique operational requirements.

Price

Cost is a significant factor for most businesses when selecting a dimensioning system:

- Honeywell AutoCube 8200: Priced around $10,000, it is positioned as a high-end model with advanced features that justify the higher price.

- Size-IT by Neopost: More affordable at approximately $5,000, making it an attractive option for small to mid-sized businesses with budget constraints.

While the AutoCube 8200 is more expensive, its superior accuracy, speed, and customization capabilities may offer better long-term value for larger businesses. In contrast, Size-IT by Neopost provides a cost-effective solution without significantly compromising on performance.

Choosing the Right System for Your Business

The choice between the Honeywell AutoCube 8200 and Size-IT by Neopost depends on several factors:

- Business Size: Large-scale businesses with higher budgets may benefit more from the advanced features of the Honeywell AutoCube 8200.

- Budget Constraints: Smaller businesses or startups might find the Size-IT by Neopost more financially viable.

- Operational Needs: Businesses requiring high customization and handling of various package types may prefer the AutoCube, while those seeking straightforward, efficient solutions may opt for Size-IT.

- Package Types: Companies dealing with a wide range of package sizes and shapes might favor the versatility of the AutoCube.

Both systems offer high levels of accuracy, speed, and user-friendliness, ensuring that businesses can streamline their shipping and logistics operations effectively.

Conclusion and Final Thoughts

Selecting the right dimensioning system is crucial for efficient and accurate package processing. The Honeywell AutoCube 8200 and Size-IT by Neopost are both excellent choices, each with unique strengths:

- Honeywell AutoCube 8200: Best suited for large enterprises seeking advanced features, higher accuracy, and extensive customization.

- Size-IT by Neopost: Ideal for smaller businesses looking for an affordable, reliable, and easy-to-use dimensioning system.

By assessing your business's specific needs, budget, and operational requirements, you can choose the dimensioning system that best aligns with your goals, ensuring efficient and cost-effective package handling.