How Kitting Areas Can Elevate Your 3PL Operations

Optimizing warehouse operations is paramount in third-party logistics (3PL). Kitting areas have emerged as a crucial element in enhancing 3PL warehouse efficiency. A kitting area is a designated workspace within a warehouse where individual components, parts, or materials are gathered and assembled into a complete kit for a specific order or product. In this article, we will discuss the benefits of implementing kitting areas in 3PL warehouses and how businesses can leverage this technology to advance their operations.

The Benefits of Implementing Kitting Areas in Your 3PL Warehouse

Implementing a kitting area in your 3PL warehouse can significantly improve your warehouse operations in the following ways:

- Enhanced Efficiency: Kitting areas optimize space and labor, streamlining the fulfillment process.

- Reduced Turnaround Time: With all necessary components in one place, managing and executing orders becomes easier, significantly reducing the turnaround time for order fulfillment.

- Improved Quality Control: Kitting ensures that all necessary parts are collected and checked for accuracy before assembly, reducing errors and enhancing quality control.

- Better Inventory Management: By consolidating all necessary materials, kitting areas improve inventory management and reduce overhead costs associated with storing extra stock.

Another benefit of implementing kitting areas in your 3PL warehouse is the reduced risk of lost or misplaced items. With all necessary components in one place, tracking inventory becomes easier, ensuring that all items are accounted for. This helps prevent delays in the fulfillment process and improves customer satisfaction.

Additionally, kitting areas enhance workplace safety by reducing the need for workers to move around the warehouse to gather materials. By having all necessary components in one location, workers can stay in one area, reducing the risk of accidents or injuries caused by moving heavy or bulky items.

Understanding the Basics of Kitting and How It Can Improve Your Operations

Understanding the fundamentals of kitting is essential to maximize its impact on your 3PL warehouse operations. The process involves gathering individual components and materials necessary to assemble a finished product or fulfill an order. Once gathered, the parts are inspected to ensure accuracy, then assembled into a complete product kit and prepared for shipping. The kitting process can be automated or conducted manually, depending on the available technology and preference.

One significant benefit of kitting is reducing the time and cost associated with order fulfillment. By pre-assembling kits, the picking and packing process is streamlined, reducing the time it takes to fulfill an order. This enables meeting customer demands more quickly and efficiently, leading to increased customer satisfaction and loyalty.

Another advantage of kitting is the reduction of errors in the order fulfillment process. By inspecting individual components before assembling them into a kit, errors or defects are caught early, reducing the likelihood of shipping incorrect or defective products to customers. This helps maintain a high level of quality control and reduces costs associated with returns and customer complaints.

Streamlining Your Fulfillment Process with Kitting Areas

Kitting areas streamline the fulfillment process by gathering all necessary parts in one location, reducing the time it takes to collect individual components. The process ensures all parts are available and in the correct quantity before initiating production, reducing the need for multiple production runs and decreasing turnaround time. This leads to happier customers, higher throughput, and less waste.

Additionally, kitting areas improve inventory management by providing a clear view of stock levels of individual components. This facilitates better planning and forecasting of inventory needs, reducing the risk of stockouts and overstocking. Kitting areas also assist in quality control by ensuring all components are inspected and verified before being used in production, reducing the risk of defects and product recalls. Overall, implementing kitting areas significantly impacts the efficiency and effectiveness of your fulfillment process.

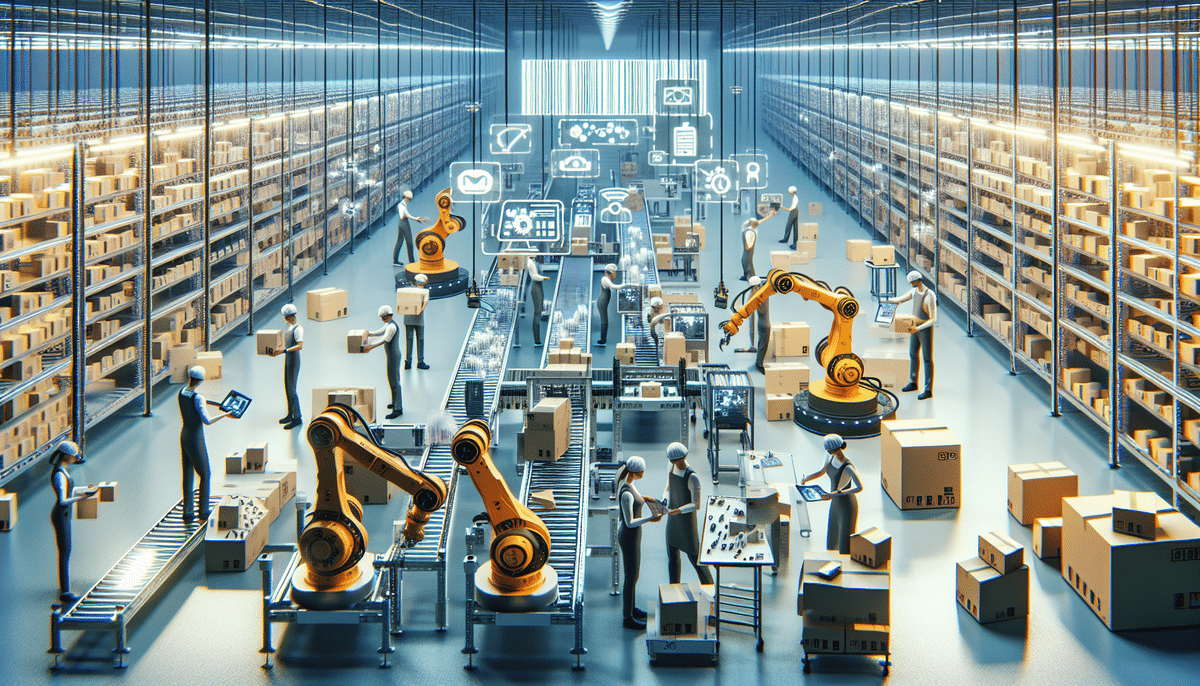

The Role of Technology in Improving Kitting Area Efficiency

Implementing the right technology can amplify the benefits of a kitting area. For example, warehouse management systems can automate the kitting process, ensuring real-time inventory updates and reducing labor costs. Additionally, barcode scanners can track inventory throughout the kitting process, improving accuracy and reducing order errors. Utilizing technology optimizes kitting area efficiency and simplifies the management of labor and materials.

Another technology that can improve kitting area efficiency is RFID (Radio Frequency Identification). RFID tags can be attached to inventory items, allowing for real-time tracking and monitoring of inventory levels. This helps prevent stockouts and overstocking, as well as reduce the time and effort required for manual inventory counts. RFID technology also improves the accuracy of inventory data, which can lead to better decision-making and more efficient use of resources.

Case Studies: Successful Implementation of Kitting Areas in 3PL Warehouses

Several 3PL companies have successfully implemented kitting areas in their warehouse operations. For instance, XYZ Logistics reduced pick-to-ship times by 50% after implementing kitting areas. Another example is ABC Manufacturing, which decreased inventory levels by 80% and turnaround times by up to a week with kitting areas.

LMN Supply Chain also experienced significant benefits from implementing kitting areas, including a 30% reduction in labor costs and a 95% increase in order accuracy. This enabled them to take on more clients and boost their revenue.

However, it's important to note that implementing kitting areas requires careful planning and consideration of the specific needs of the warehouse and its clients. For example, QRS Distribution attempted to implement kitting areas without fully understanding the impact on their operations, resulting in increased errors and delays. They ultimately had to revert to their previous system. Proper planning and communication with clients are crucial for the successful implementation of kitting areas.

How to Train Your Staff to Utilize Kitting Areas Effectively

Training your staff on the proper use of kitting areas is essential to maximize their impact. The training should cover process flows, safety protocols, and best practices to enhance efficiency. Additionally, implementing a comprehensive training program can help reduce errors and improve overall workplace efficiency.

One important aspect of training your staff on kitting areas is emphasizing the importance of organization. Proper organization of materials and tools can significantly reduce the time it takes to complete a task and minimize the risk of errors. Encourage your staff to keep the kitting area clean and tidy, and to return tools and materials to their designated locations after use.

Another key element of effective kitting area utilization is communication. Encourage your staff to communicate with each other about the status of tasks and the availability of materials. This can help prevent delays and ensure that everyone is working efficiently towards the same goal. Consider implementing a communication system, such as a whiteboard or messaging app, to facilitate this process.

The Cost-Benefit Analysis of Investing in Kitting Areas for Your 3PL Business

A cost-benefit analysis of implementing a kitting area in your 3PL warehouse depends on several factors, such as current warehouse operations, order volume, labor costs, and available technology. Generally, the benefits outweigh the costs. Investing in kitting areas can result in improvements in efficiency, speed, accuracy, cost savings, and customer satisfaction.

One of the key benefits of implementing a kitting area is the reduction in order processing time. By having all necessary items for an order in one location, pickers can quickly gather all items needed for an order, reducing fulfillment time. This leads to faster turnaround times and increased customer satisfaction. Additionally, kitting areas help reduce errors in order fulfillment, as all items are checked and verified before being sent out to customers.

Best Practices for Maintaining and Optimizing Your Kitting Area Operations

Maintaining and optimizing your kitting area operations is essential to realize the full benefits of this technology. Best practices include regular audits and maintenance to ensure equipment and processes are performing well. Additionally, analyzing data and using it to drive process improvements can help enhance kitting area operations and maximize the benefits of this technology.

Another best practice is establishing clear and concise standard operating procedures (SOPs). SOPs provide a framework for consistent and efficient operations, reducing the risk of errors and delays. Regular training and communication with employees on these procedures help ensure that everyone is aligned and following the same processes.

Finally, regularly reviewing and updating your kitting area operations ensures they meet the changing needs of your business. This may involve incorporating new technologies or processes, adjusting staffing levels, or reorganizing the physical layout of the kitting area. By staying proactive and adaptable, you can continue to optimize your kitting area operations and stay ahead of the competition.

The Future of Kitting Areas in the Evolving Landscape of 3PL Warehousing

As e-commerce demand continues to grow, 3PL warehousing operations will continue to evolve, with kitting areas playing a crucial role in this evolution. With the rise of omnichannel retailing and same-day delivery, kitting areas will become even more critical in streamlining the fulfillment process and ensuring customer satisfaction.

One key challenge facing 3PL warehousing operations is the need for greater flexibility in kitting areas. As retailers and e-commerce companies offer a wider range of products, 3PL providers must quickly adapt their kitting areas to accommodate new products and packaging requirements. This requires investments in technology and equipment, as well as a more agile approach to warehouse design and layout.

An important trend in the future of kitting areas is the increasing use of automation and robotics. As the cost of automation technology continues to decline, 3PL providers can invest in more advanced systems that handle a wider range of products and packaging types. This not only improves efficiency and accuracy in the kitting process but also reduces the risk of workplace injuries and enhances overall warehouse safety.

Conclusion

Implementing kitting areas in 3PL warehouses can significantly improve warehouse operations and streamline the fulfillment process. Optimizing kitting area operations through technology and best practices can lead to significant cost savings, improved efficiency, and increased customer satisfaction. As 3PL warehousing operations continue to evolve, kitting areas will remain a critical business tool in advancing operations to the next level.