How to Achieve Acceptable Warehouse Shrinkage

Warehouse shrinkage is a pervasive challenge affecting numerous businesses within the supply chain industry. It denotes the gap between expected inventory levels and the actual stock verified during physical counts. Shrinkage can stem from various factors, including theft, damage, administrative errors, and ineffective stock management. This article delves into comprehensive strategies to prevent and mitigate warehouse shrinkage, ensuring your business operates efficiently and profitably.

Understanding the Concept of Warehouse Shrinkage

Before exploring prevention strategies, it's crucial to grasp the concept of warehouse shrinkage. It can be categorized into:

- Operational Loss: Caused by theft, damage during transport, and misplacement of goods.

- Administrative Loss: Results from improper inventory management due to inadequate software or insufficient training, often manifesting as clerical, mathematical, and record-keeping errors.

Operational loss further divides into:

- Internal Theft: When employees steal goods from the warehouse.

- External Theft: Occurs when outsiders steal goods by breaking into the warehouse.

Additionally, natural causes such as spoilage, expiration, and obsolescence can contribute to shrinkage by decreasing inventory value, leading to significant financial losses. Implementing robust inventory management systems is essential to prevent these losses.

Common Causes of Warehouse Shrinkage and How to Prevent Them

The primary cause of warehouse shrinkage is theft. To combat this, businesses should establish strict security protocols, including:

- Special access cards or biometric measures for entry control.

- Surveillance cameras strategically placed throughout the warehouse.

Another significant cause is damage. Prevention strategies include:

- Using high-quality storage materials.

- Training employees on proper handling procedures.

Misplacement can be addressed by leveraging technology such as:

- Barcodes and RFID tags.

- GPS systems for tracking inventory location.

Proper labeling of all inventory locations also ensures accuracy and correct item placement.

Administrative errors, like incorrect data entry or inaccurate inventory counts, can be minimized by:

- Implementing regular audits and checks.

- Using advanced inventory management software.

Employee fraud can be curtailed through:

- Conducting thorough background checks.

- Regular monitoring of employee behavior.

By addressing these causes comprehensively, businesses can significantly reduce warehouse shrinkage and enhance their bottom line.

Steps to Take When You Encounter Warehouse Shrinkage

Upon discovering discrepancies, warehouse managers should promptly:

- Launch investigations to identify the loss causes.

- Take corrective actions based on findings.

- Involve employees in the investigation process.

- Provide adequate training and resources to mitigate future issues.

Implementing a robust inventory management system is essential. Such a system should encompass:

- Regular inventory counts.

- Tracking inventory movement.

- Monitoring inventory levels in real-time.

Additionally, deploying security measures like surveillance cameras, access controls, and security personnel can deter theft and reduce shrinkage risks. Proactive measures not only save businesses from significant losses but also maintain customer trust.

The Importance of Implementing a Robust Inventory Management System

A well-designed inventory management system is vital for preventing warehouse shrinkage. Key features should include:

- Accurate forecasting and data analysis.

- Comprehensive snapshots of inventory levels.

- Vendor compliance and proper receiving procedures.

- Efficient handling of returns and damaged merchandise.

Such systems not only mitigate shrinkage but also enhance overall business operations by:

- Reducing the risk of stockouts.

- Optimizing inventory levels.

- Improving order fulfillment times.

- Providing insights into customer demand and purchasing patterns.

Implementing a robust inventory management system allows businesses to make data-driven decisions, enhancing inventory and supply chain management strategies.

Best Practices for Tracking and Monitoring Inventory Levels

Effective inventory tracking involves:

- Implementing an accessible and user-friendly inventory tracking system that logs all changes to inventory levels.

- Providing real-time updates to adjust forecasts and reorder points promptly.

- Conducting regular physical inventory counts to compare actual stock with recorded levels, investigating discrepancies promptly.

- Using automated inventory management systems with barcode scanning or RFID technology to streamline tracking and reduce human error.

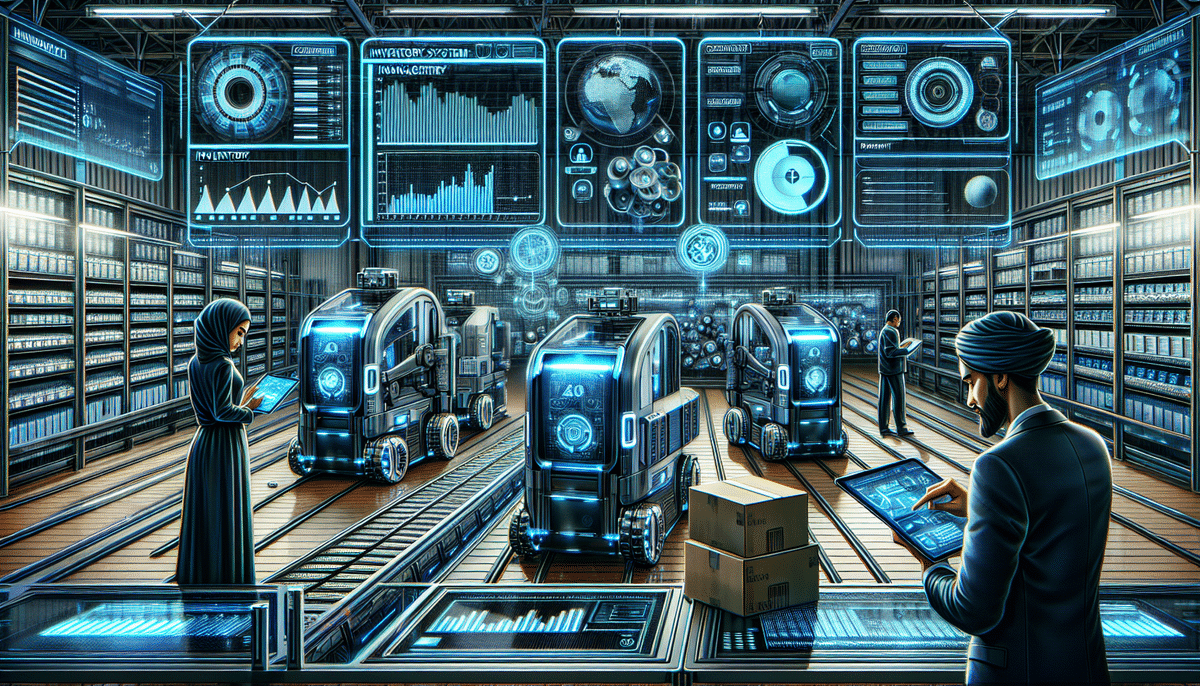

The Role of Technology in Reducing Warehouse Shrinkage

Technology plays a pivotal role in diminishing warehouse shrinkage by enhancing inventory management accuracy and efficiency. Key technologies include:

- RFID: Enables precise tracking of inventory movement.

- Warehouse Automation: Streamlines product handling and order fulfillment processes.

- Machine Learning: Analyzes patterns to predict and prevent potential shrinkage incidents.

Furthermore, a robust security system incorporating surveillance cameras, access control systems, and security personnel can significantly deter theft and minimize inventory damage risks.

How to Train Employees on Preventing and Addressing Warehouse Shrinkage

Employees are integral to minimizing warehouse shrinkage. Effective training programs should cover:

- Proper handling and storage of inventory.

- Controlling inventory expenses.

- Accurate record-keeping and utilization of inventory management software.

Regular training sessions ensure that staff remain updated on the latest procedures and regulations. Additionally, educating employees on security measures is crucial, including:

- Implementing access control systems.

- Installing security cameras.

- Conducting regular security audits.

Employees should also be trained to identify and report suspicious activities, such as theft or unauthorized inventory access.

Incentivizing employees can further enhance their commitment to preventing shrinkage. This can be achieved by:

- Offering bonuses or rewards for meeting shrinkage reduction goals.

- Recognizing employees who consistently adhere to proper inventory management procedures.

Motivated employees are more likely to take an active role in maintaining accurate inventory records and preventing shrinkage.

Key Metrics to Monitor When Measuring Warehouse Shrinkage

To effectively measure warehouse shrinkage, businesses should track the following metrics:

- Frequency and severity of losses.

- Root causes of shrinkage incidents.

- Total cost of losses.

- Inventory turnover rates.

- Employee turnover rates, as high turnover can increase shrinkage risks due to inconsistent handling procedures.

Monitoring these metrics helps identify trends that may lead to losses, enabling businesses to implement corrective actions swiftly.

Strategies for Reducing the Impact of External Factors on Warehouse Shrinkage

External factors like natural disasters, business cycles, and political changes can influence warehouse shrinkage. To mitigate these impacts, businesses should:

- Develop flexible plans that account for geographically diverse suppliers.

- Ensure the ability to quickly shift production in response to disruptions.

- Implement real-time monitoring of the supply chain to identify and address issues promptly.

Additionally, strengthening security systems by:

- Installing surveillance cameras.

- Hiring security personnel.

- Implementing strict access control measures.

can deter theft and protect inventory from vandalism or break-ins caused by external factors.

Developing a comprehensive risk management plan is also essential. This plan should:

- Identify potential risks.

- Develop strategies to mitigate identified risks.

- Include regular assessments and updates to remain effective against evolving external factors.

Case Studies: Successful Approaches for Addressing and Mitigating Warehouse Shrinkage

Numerous case studies highlight effective strategies for preventing and mitigating warehouse shrinkage, including:

- Implementing automated inventory management systems.

- Adopting RFID technology for precise tracking.

- Conducting regular staff training sessions.

- Thoroughly investigating shrinkage losses to identify and address root causes.

For example, one case study demonstrated that implementing a strict access control system, limiting the number of employees with access to high-value items, significantly reduced shrinkage. Another case study highlighted the effectiveness of security cameras and alarms in deterring theft and providing evidence for investigations.

Businesses should regularly review and update their shrinkage prevention strategies to incorporate new technologies and methodologies. Staying informed and proactive enables businesses to minimize financial losses and operational disruptions caused by warehouse shrinkage.

The Future of Warehouse Management: Predictive Analytics and AI Solutions to Reduce Shrinkage

Looking ahead, predictive analytics and AI technologies are set to revolutionize warehouse management by predicting and preventing shrinkage. These emerging technologies offer real-time data and insights, empowering businesses to make informed decisions regarding inventory management, forecasting, and other critical processes.

Key benefits include:

- Optimizing warehouse layout and design by analyzing product movement and order fulfillment data.

- Identifying areas for improvement to increase efficiency and reduce costs, such as reorganizing product placement and adjusting staffing levels.

- Implementing automation technologies to streamline operations.

Moreover, predictive analytics and AI contribute to sustainability by:

- Reducing waste through better inventory forecasting.

- Improving energy efficiency by analyzing usage patterns and optimizing systems.

- Minimizing transportation fuel consumption by optimizing routes.

These technologies not only enhance operational efficiency but also support businesses in achieving their sustainability goals.

Conclusion: A Recap of Steps to Achieve Acceptable Warehouse Shrinkage

Warehouse shrinkage can significantly impede business growth and profitability. However, businesses can effectively prevent and mitigate shrinkage by:

- Investing in secure storage solutions and advanced security systems.

- Enhancing employee training and incentivizing proper inventory management practices.

- Implementing proficient inventory management systems and utilizing cutting-edge technology.

By adhering to these strategies and continuously adapting to new challenges and technologies, businesses can manage warehouse shrinkage effectively, safeguarding their financial health and operational integrity.