Introduction to UPS Worldship and Zebra Label Printers

Managing a business that relies heavily on shipping requires efficient labeling processes. Misaligned labels can lead to delayed, returned, or lost packages, which disrupts operations and customer satisfaction. By integrating UPS Worldship with a Zebra Label Printer, you can optimize your labeling process to avoid these issues.

Overview of UPS Worldship

UPS Worldship is a comprehensive shipping software designed to streamline the shipping process for businesses of all sizes. It offers tools for managing shipments, tracking packages, and printing shipping labels, among other features. Integrating it with reliable label printers like Zebra ensures accurate and efficient label production.

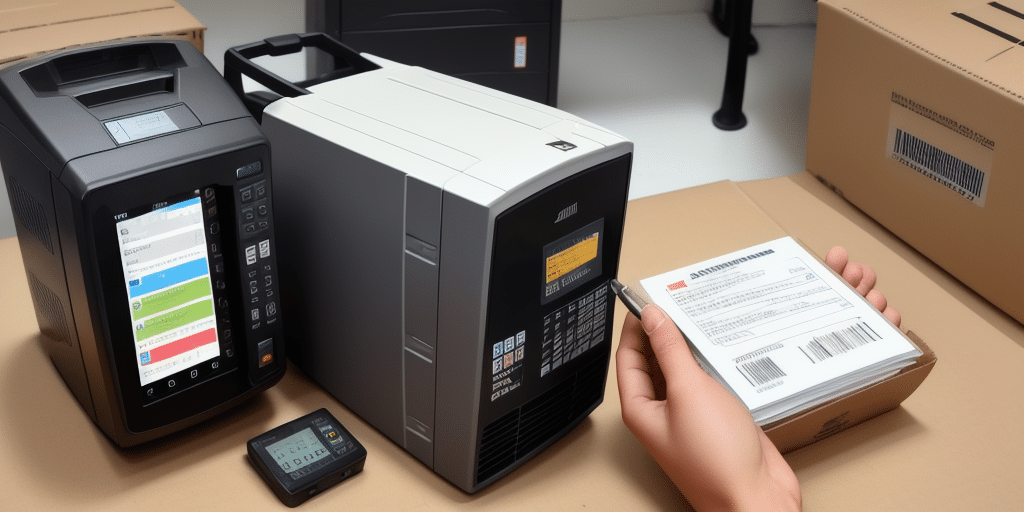

Basics of Zebra Label Printers

Zebra Label Printers utilize thermal transfer technology to produce high-quality, durable labels. Renowned for their reliability and ease of use, these printers are compatible with major shipping software, including UPS Worldship. They are not only used in shipping but also in industries like healthcare, retail, and manufacturing for various labeling needs.

Importance of Padding Settings in Label Printing

Adjusting the padding settings in your label printer is crucial for several reasons. Proper padding ensures that labels are aligned correctly, avoids overlapping or cut-off information, and enhances the overall efficiency of your shipping process.

Ensuring Label Alignment and Efficiency

Padding refers to the space between the label content and the edge of the label paper. Correct padding settings prevent misalignment, ensuring that each label is printed accurately. This precision reduces errors in shipping information, leading to faster and more reliable delivery.

Cost Savings through Proper Padding

Incorrect padding can lead to wasted labels, as misaligned prints may require reprints or result in unusable labels. By optimizing padding settings, businesses can minimize wasted resources, leading to significant cost savings over time.

Maintaining a Professional Image

Labels that are well-aligned and free from errors convey professionalism and attention to detail. This not only enhances the perceived quality of your business but also builds trust with customers and partners, fostering a positive reputation.

Configuring and Customizing Padding Settings

To achieve optimal label printing, it's essential to properly configure and customize the padding settings in UPS Worldship when using a Zebra Label Printer. This section outlines the steps to configure your printer and adjust padding for various label sizes and business needs.

Setting Up Zebra Label Printer with UPS Worldship

Begin by ensuring that your Zebra Label Printer is correctly configured to work with UPS Worldship. Refer to the Zebra support documentation for detailed setup instructions. Proper configuration is the foundation for accurate label printing.

Adjusting Padding for Different Label Sizes

Different label sizes may require varied padding settings. Smaller labels typically need less padding, while larger labels may benefit from more. Experiment with different padding configurations within UPS Worldship to determine the optimal settings for each label size used in your business.

Tailoring Padding to Business Needs

Beyond label size, padding settings can be customized to accommodate branding elements, such as logos, or to meet specific shipping regulations. Consider the type of label material and the environmental conditions the labels will face to ensure adhesion and durability.

Troubleshooting and Best Practices

Even with proper configuration, issues may arise in label printing. Understanding common problems and adhering to best practices can help maintain smooth operations.

Common Issues with Padding Settings

Typical issues include labels being cut off, misaligned, or overlapping. These problems often stem from incorrect printer settings or worn-out print heads. Regular maintenance and calibration are essential to prevent such errors.

Best Practices for Adjusting Padding Settings

Adopt the following best practices to optimize padding settings:

- Test Labels: Always print a small batch of labels to verify settings before mass production.

- Update Firmware: Keep your printer's firmware up to date to ensure compatibility and performance.

- Clean Printer Regularly: Maintain the print head and rollers to prevent smudging and streaking.

- Match Label Size to Printer: Ensure that the label size corresponds with the printer's specifications to avoid printing errors.

- Store Supplies Properly: Keep extra labels and ink on hand to prevent downtime due to supply shortages.

Conclusion: Streamlining Your Shipping Process with Proper Padding Settings

Optimizing the padding settings in UPS Worldship with a Zebra Label Printer can significantly enhance your shipping process. It reduces errors, saves costs, and upholds a professional image for your business. By following the best practices outlined above, you can ensure efficient and accurate label printing, leading to improved customer satisfaction and business success.

Properly padded packages protect contents during transit, minimizing the risk of damage and associated costs from returns or replacements. Additionally, compliant padding reduces the likelihood of incurring extra fees from shipping carriers for improperly labeled packages.

Ultimately, investing time in fine-tuning your padding settings fosters reliability in your shipping operations, contributing to positive customer experiences and sustained business growth.