How to Choose the Right Location for Your Fulfillment Warehouse

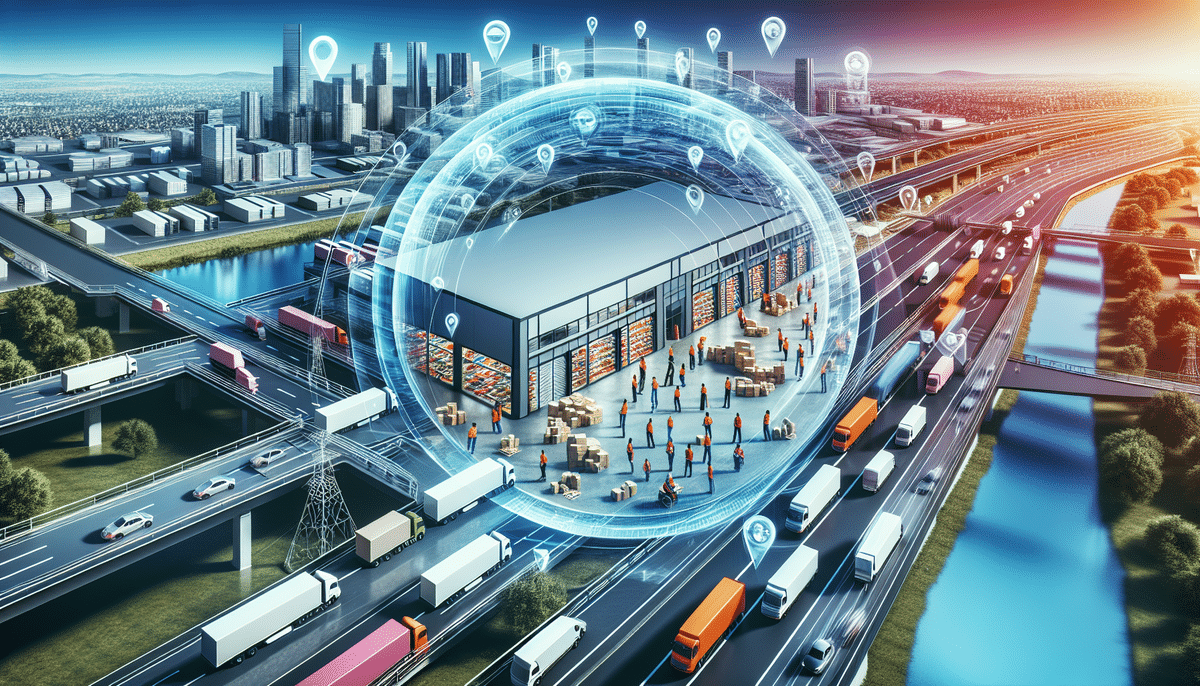

Fulfillment warehouses are a critical component of any e-commerce business, with their location significantly impacting the efficiency and cost-effectiveness of your supply chain. According to a study by Supply Chain Digest, strategic warehouse location can reduce transportation costs by up to 20% and improve delivery times by 30%. In this article, we delve into the key factors to consider when selecting the optimal location for your warehouse. We will examine your target market, delivery network, availability of skilled labor, and provide a comprehensive site visit checklist to guide you through the site selection process.

The Importance of Location in Supply Chain Management

The significance of location in supply chain management cannot be overstated. The location of your fulfillment warehouse is a pivotal factor in determining the speed and cost of order delivery, as well as the overall efficiency of your operations. According to the IBM Supply Chain Report, optimized warehouse location can lead to a 15% decrease in transportation costs and a 25% improvement in delivery times. Choosing the right location can significantly reduce transportation costs, improve delivery times, and enhance customer service.

Conversely, selecting a location without careful consideration of all relevant factors can result in increased fulfillment costs, longer delivery times, and potentially lost sales. Therefore, conducting a thorough analysis of factors such as proximity to major transportation routes, availability of skilled labor, local tax incentives, and real estate costs is essential. Additionally, assessing the potential impact of natural disasters or other disruptions on your operations is critical. By meticulously evaluating these aspects, you can make an informed decision on the optimal location for your fulfillment warehouse, ensuring that your supply chain is primed for success.

Understanding the Types of Fulfillment Warehouses

Before delving into the site selection process, it's crucial to understand the various types of fulfillment warehouses. Broadly, there are two main categories of fulfillment centers:

- Standalone Warehouses: These are owned and operated by a single organization and are used exclusively for its fulfillment operations. They offer complete control over operations but may require significant investment.

- Shared Warehouses: Owned by third-party logistics providers (3PLs), these facilities offer warehousing and fulfillment services to multiple businesses. Shared warehouses are often more cost-effective and flexible than standalone warehouses, making them an attractive option for small businesses or those with seasonal demand fluctuations.

Additionally, there are Hybrid Fulfillment Warehouses that combine elements of both standalone and shared facilities. Typically owned by a single organization, these warehouses offer excess capacity to other businesses, allowing owners to generate additional revenue while maximizing warehouse space utilization. Hybrid fulfillment warehouses are suitable for businesses with variable capacity needs or those seeking to diversify revenue streams.

Factors to Consider When Choosing the Best Location for Your Fulfillment Warehouse

Selecting the optimal location for your fulfillment warehouse involves evaluating several key factors:

- Proximity to Customers: Locating your fulfillment warehouse close to your customer base is fundamental. According to Forbes, shorter transportation distances can reduce fulfillment costs by up to 20% and improve delivery times by 25%.

- Access to Transportation Infrastructure: Ensure your warehouse is near major highways, ports, airports, and railways. Easy access facilitates efficient movement of goods, reduces transit times, and lowers transportation costs. For example, proximity to a major port can decrease shipping times and costs for international orders.

- Availability of Skilled Labor: The presence of a skilled workforce is crucial for maintaining operational efficiency. Areas with access to vocational schools or training programs can provide a steady stream of qualified employees, reducing hiring and training costs.

- Real Estate Costs: Real estate prices vary significantly across different regions. Conducting a thorough cost-benefit analysis will help determine which location offers the best value within your budget constraints. Websites like LoopNet can provide current real estate market data.

- Infrastructure and Utilities: Reliable infrastructure and utility services, including electricity, water, and high-speed internet, are vital for efficient warehouse operations. Assess the reliability and capacity of these services in potential locations to prevent operational disruptions.

Analyzing Your Target Market and Delivery Network for Optimal Location Selection

Effective location selection begins with a deep understanding of your target market and delivery network. Analyzing where your customers are concentrated and how they prefer to receive their orders is essential in pinpointing the most strategic warehouse locations. For example, if a significant portion of your customer base resides on the East Coast, positioning your warehouse in that region can reduce shipping distances, thereby lowering costs and enhancing delivery speed.

Similarly, if your operations depend heavily on air or ocean freight for inbound shipments, situating your warehouse near major airports or ports can optimize logistics efficiency. According to the Bureau of Transportation Statistics, proximity to these transportation hubs can decrease inbound transit times by up to 30%, ensuring timely restocking and minimizing potential delays.

The Impact of Local Regulations and Taxes on Your Warehouse's Bottom Line

Local regulations and taxes can substantially influence the operational costs of your warehouse. Compliance with zoning laws, building codes, and environmental regulations may increase both the initial construction and ongoing leasing costs. Additionally, taxes such as property, sales, and employment taxes directly affect your warehouse's profitability.

For instance, states like Wyoming offer no state property tax, which can result in significant savings compared to states with high property tax rates. Understanding the tax incentives and regulatory landscape can help you identify locations that not only minimize costs but also provide a more favorable business environment.

How Geographical Considerations Affect the Efficiency and Cost of Transportation

Geographical factors play a pivotal role in shaping the efficiency and cost of transportation for your fulfillment warehouse. For example, shipping to and from Hawaii or Alaska typically incurs higher transportation costs compared to the contiguous United States due to their remote locations.

Regions with challenging terrains, such as mountainous or rural areas, can also lead to increased transportation expenses and longer delivery times. According to the U.S. Department of Transportation, logistical challenges in remote or difficult terrains can result in up to a 15% increase in transportation costs.

Therefore, when selecting a warehouse location, it is crucial to evaluate how geographical elements might influence your transportation strategy and overall supply chain efficiency.

The Pros and Cons of Rural vs Urban Warehouse Locations

Choosing between rural and urban warehouse locations involves weighing a variety of advantages and disadvantages:

- Urban Locations:

- Pros: Proximity to large customer bases, robust transportation infrastructure, and easier access to a skilled workforce.

- Cons: Higher real estate and labor costs can significantly increase operational expenses.

- Rural Locations:

- Pros: Lower real estate and labor costs, potential tax incentives, and less congestion, which can streamline operations.

- Cons: Limited access to transportation infrastructure, potential difficulties in attracting a skilled workforce, and longer distances to major markets.

Ultimately, the decision between rural and urban warehouse locations should align with your business objectives, budgetary constraints, and the specific needs for logistical efficiency and market accessibility.

The Role of Proximity to Ports, Airports, and Railways in Warehouse Site Selection

Proximity to major transportation hubs such as ports, airports, and railways is a critical factor in warehouse site selection, directly influencing the cost and efficiency of your fulfillment operations.

Ports and Airports: Warehouses located near ports and airports can expedite the receipt of goods, reducing inbound shipping times. This is particularly important for businesses reliant on international trade or rapid re-stocking. For instance, proximity to the Port of Los Angeles, the busiest container port in the U.S., can significantly benefit businesses engaged in importing goods.

Railways: Access to rail transport offers a cost-effective solution for the bulk movement of goods. Railways can handle large volumes efficiently, often at lower costs per unit compared to road transport. Locations near major rail lines or intermodal facilities enhance flexibility in shipping options, allowing businesses to adapt to varying logistical needs.

According to the National Safety Council, efficient connections to these transportation modes can reduce overall shipping costs by up to 15% and decrease delivery times by 20%.

Evaluating the Availability of Skilled Labor and Workforce in a Specific Area

The availability of skilled labor is critical for the success of your fulfillment operation. Consider the availability of skilled workers in the specific area you are considering. Are there vocational schools or training programs nearby that can help you attract and retain skilled workers? Understanding the availability and quality of the workforce in a particular area is essential for making an informed decision on location selection.

For example, areas with strong manufacturing or logistics industries often have a ready pool of trained professionals. According to the Bureau of Labor Statistics, regions with higher education institutions offering logistics and supply chain programs tend to have lower unemployment rates in these fields, ensuring a steady supply of qualified employees for your warehouse operations.

Comparing the Real Estate Costs Across Different States and Metropolitan Areas

Real estate costs can vary significantly across different states and metropolitan areas. Conducting a cost-benefit analysis is essential for determining the best value for your budget. Consider the cost of leasing or purchasing a warehouse in the locations you are considering, as well as the availability of real estate for expansion or future needs.

Websites like LoopNet and CREXi provide up-to-date market data on commercial real estate, enabling businesses to compare prices and availability across multiple regions. Additionally, factoring in potential rental growth rates and property value appreciation can help in forecasting long-term real estate costs and investment returns.

The Importance of Infrastructure and Utilities When Choosing a Fulfillment Warehouse Location

Adequate infrastructure and utility services are critical for running an efficient fulfillment operation. Consider the availability and reliability of electricity, water, internet connectivity, and other essential services in the location you are considering. Understanding the infrastructure and utility needs of your business is essential for selecting a warehouse location that can meet those needs.

According to the U.S. Chamber of Commerce, reliable utilities can prevent costly downtime and ensure smooth warehouse operations. Additionally, areas with advanced technological infrastructure, such as high-speed internet and smart grid utilities, can enhance operational efficiency and support modern warehouse management systems.

Preparing a Site Visit Checklist to Ensure an Informed Decision-Making Process

When considering a location for your warehouse, it's important to conduct a site visit to assess the suitability of the location for your business. To ensure that your site visit is productive and useful, it's a good idea to prepare a checklist ahead of time. This list should include all relevant factors, such as proximity to transportation infrastructure, availability of labor, and real estate costs. By being organized and systematic during your site visit, you can make an informed decision on the best location for your fulfillment warehouse.

- Transportation Access: Evaluate the ease of access to highways, ports, airports, and railways.

- Local Workforce: Assess the availability and quality of the local labor pool.

- Facility Condition: Inspect the physical condition of the warehouse space.

- Infrastructure: Check the reliability of utilities and technological infrastructure.

- Regulatory Compliance: Ensure the site meets all local zoning and environmental regulations.

- Growth Potential: Consider the potential for future expansion and scalability.

Utilizing a comprehensive checklist can help identify potential issues and opportunities, facilitating a more informed and strategic location decision.

Case Studies: Examples of Successful Warehouse Locations Across Industries

Looking at examples of successful warehouse locations across industries can be a helpful way to understand how different factors impact the site selection process. For instance, an e-commerce company that specializes in high-tech gadgets may choose to locate its warehouse in a tech hub like Silicon Valley to access a skilled workforce and a vibrant business ecosystem. Similarly, a company that specializes in international trade may choose to locate its warehouse near a major port to facilitate the movement of goods across borders.

Another example is the retail giant Amazon, which strategically places its fulfillment centers near major urban areas and transportation hubs to ensure rapid delivery times and efficient logistics. Additionally, automotive companies often locate their warehouses in regions with strong manufacturing bases to streamline supply chain operations.

By researching examples of successful warehouse locations in your industry, you gain valuable insights into what factors are most important for your specific business.

Tips for Negotiating Leases, Permits, and Zoning Requirements with Local Authorities

Once you have identified a suitable location for your fulfillment warehouse, the next step is to negotiate leases, permits, and zoning requirements with local authorities. This process can often be complicated, and it's essential to prepare adequately beforehand. Research the local regulations and requirements and be prepared to negotiate with local authorities to ensure that you can get the best deal for your business.

Here are some tips to facilitate this process:

- Understand Local Zoning Laws: Familiarize yourself with the zoning regulations to ensure your warehouse operations are compliant.

- Engage Local Experts: Hiring a local real estate agent or legal advisor can provide invaluable insights and assistance.

- Explore Incentives: Many local governments offer tax incentives, grants, or rebates to attract businesses. Inquire about available programs that can reduce your setup costs.

- Negotiate Lease Terms: Aim for flexible lease terms that allow for future expansion and include favorable clauses regarding maintenance and repairs.

- Build Relationships: Establishing a positive relationship with local authorities can facilitate smoother negotiations and quicker permit approvals.

Proper preparation and strategic negotiation can lead to favorable lease agreements and ensure that your warehouse complies with all local regulations.

Future-Proofing Your Fulfillment Warehouse Location Decision: Anticipating Trends and Challenges

Selecting the right location for your warehouse is not a one-time decision but rather an ongoing process. Anticipating future trends and challenges can help you make strategic decisions about the location of your warehouse. For example, if you anticipate a shift towards e-commerce platforms in the future, you may choose to locate your warehouse in an area that is well-equipped to handle e-commerce logistics.

Similarly, if you anticipate changes in the regulatory or tax environment, you may choose to locate your warehouse in an area that is less likely to be impacted by those changes. Emerging trends, such as the adoption of automation and robotics in warehouses, may also influence your location decision. Areas with access to advanced technological infrastructure can better support these innovations, enhancing operational efficiency.

According to the PwC Future of Work report, businesses that proactively anticipate and adapt to industry trends are more likely to sustain long-term growth and competitiveness.

Conclusion

Choosing the right location for your fulfillment warehouse is a critical decision that can impact the overall efficiency and cost-effectiveness of your supply chain. By taking all relevant factors into consideration, including proximity to customers, access to transportation infrastructure, availability of skilled labor, and real estate costs, you can make an informed decision that meets the needs of your business.

Incorporating data-driven insights, understanding industry trends, and leveraging reputable sources can further enhance your site selection process. By following these guidelines, you are well on your way to selecting a warehouse location that can help you achieve your business goals and maintain a competitive edge in the market.