The Importance of Effective Inventory Management

Effective inventory management is a cornerstone of successful business operations. It ensures that a company maintains the right balance of stock to meet customer demand without overstocking or understocking, which can have significant financial implications.

Benefits to Business

- Cost Control and Efficiency: Real-time tracking of inventory levels helps identify when stock is low or when there's excess inventory. This reduces carrying costs and optimizes cash flow.

- Enhanced Customer Satisfaction: Maintaining adequate stock levels ensures that products are available when customers need them, minimizing stockouts and boosting loyalty.

- Informed Purchasing Decisions: Analyzing sales data and inventory levels helps determine which products are best-sellers and which ones aren't performing, facilitating smarter reordering and discontinuation decisions.

- Improved Supply Chain Management: Understanding inventory levels and lead times can highlight bottlenecks within the supply chain, allowing for proactive problem-solving.

According to a Forbes report, businesses with effective inventory management systems can reduce carrying costs by up to 20%.

Understanding and Forecasting Inventory Needs

Accurate forecasting is essential to maintaining optimal inventory levels. It involves predicting future inventory requirements based on various factors:

Demand Forecasting

By analyzing historical sales data, seasonal trends, and current market conditions, businesses can predict future product demand. This helps in planning inventory purchases to meet anticipated sales without overstocking.

Inventory Turnover and Ratios

Inventory turnover rates measure how often inventory is sold and replaced over a specific period. A higher turnover rate indicates efficient inventory management, whereas a lower rate may signal overstocking or slow-moving products.

Lead Time Analysis

Understanding the time it takes for suppliers to deliver products is crucial. Balancing lead times with inventory levels ensures that there's enough stock to meet demand without holding excess inventory.

Utilizing metrics like the inventory-to-sales ratio can help determine if adjustments are necessary to maintain optimal stock levels.

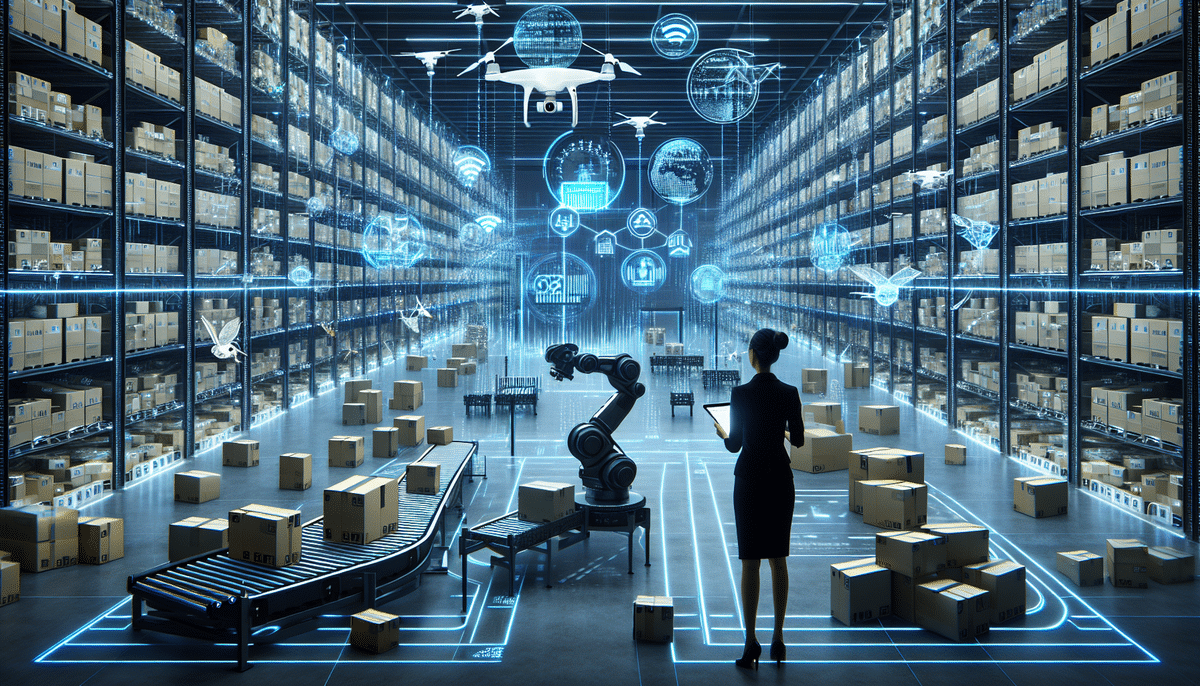

Leveraging Technology for Inventory Management

Advancements in technology have transformed inventory management, making it more efficient and accurate:

Automation and Inventory Software

Implementing inventory management software automates tasks such as stock tracking, ordering, and reordering. This reduces manual effort and minimizes errors, leading to more accurate inventory records.

Internet of Things (IoT) and Real-Time Tracking

IoT devices enable real-time tracking of inventory, providing instant data and alerts on stock levels. This ensures that businesses can respond promptly to changes in demand.

Artificial Intelligence (AI) and Predictive Analytics

AI algorithms analyze vast amounts of data to provide accurate demand forecasting and inventory optimization. Predictive analytics helps businesses anticipate market trends and adjust inventory accordingly.

For more insights on the role of technology in inventory management, refer to Forbes' analysis on AI in inventory management.

Strategies for Reordering and Maintaining Inventory

Implementing effective strategies ensures that inventory levels are maintained efficiently:

Just-in-Time (JIT) Inventory

JIT involves ordering inventory only when it's needed, which reduces storage costs and minimizes waste. This strategy requires precise forecasting and reliable suppliers.

Economic Order Quantity (EOQ)

EOQ calculates the optimal order quantity by balancing demand, lead time, and ordering costs. This minimizes holding costs and ensures that inventory levels are maintained efficiently.

Vendor-Managed Inventory (VMI)

VMI allows suppliers to manage inventory levels on behalf of the business. This can lead to reduced holding costs and improved supply chain efficiency.

Handling Deadstock and Excess Inventory

- Regular Assessments: Frequently evaluate inventory to identify slow-moving or obsolete items.

- Improve Forecasting: Enhance accuracy in demand forecasting to prevent overestimation of inventory needs.

- Liquidate Slow-Moving Inventory: Use discounts, promotions, or bundle deals to clear unsold products.

- Repurpose or Recycle: Find alternative uses for excess inventory or recycle materials where possible.

- Return to Suppliers: If feasible, return excess stock to suppliers or negotiate favorable return policies.

Proactively managing deadstock and excess inventory helps free up warehouse space, improves cash flow, and maintains a healthier inventory balance.

Best Practices for Inventory Organization and Storage

Organizing inventory effectively ensures that products are easily accessible, well-maintained, and safe:

Categorization

Group similar items together to streamline the picking and stocking processes. This improves efficiency and reduces the time spent locating products.

Labeling Storage Areas

Clearly label shelves, bins, and storage locations for quick identification. This minimizes errors and speeds up inventory management tasks.

First-In, First-Out (FIFO) System

Implement the FIFO system to ensure that older inventory is sold first, preventing stock spoilage and reducing waste.

Shelf Placement Optimization

Place high-turnover items in easily accessible locations, while slower-moving products can be stored further away. This reduces retrieval time and enhances overall efficiency.

Cleanliness and Safety

Maintain clean, well-lit, and hazard-free storage areas to protect both products and staff. Regular maintenance helps prevent damages and accidents.

Regularly reviewing and updating your storage system ensures it adapts to business growth and changes in product offerings.

Data-Driven Decision Making in Inventory Management

Utilizing data analysis provides deep insights into inventory performance, enabling informed decision-making:

Sales History Analysis

Review past sales trends to accurately forecast future demand. Understanding seasonal fluctuations and peak periods helps in planning inventory levels effectively.

Inventory Turnover Rates

Measure how quickly products are sold and replaced to assess inventory efficiency. High turnover rates indicate strong sales performance and optimal inventory levels.

Inventory-to-Sales Ratios

Determine if your inventory levels are aligned with sales. A balanced ratio ensures that you're neither overstocked nor understocked, maintaining financial health.

Supplier Performance Metrics

Analyze supplier reliability, lead times, and pricing to optimize ordering processes. Strong supplier relationships contribute to smoother inventory management.

For further reading on leveraging data for inventory management, check out Harvard Business Review's insights on data analytics in supply chain management.

Future Trends and Innovations in Inventory Management

The landscape of inventory management is continually evolving with emerging technologies and shifting business practices:

Artificial Intelligence and Machine Learning

AI and ML enhance forecasting models and provide predictive analytics, leading to better inventory optimization and reduced waste.

Blockchain Technology

Blockchain offers increased transparency and traceability in the supply chain through secure, decentralized ledgers. This ensures authenticity and reduces fraud.

Internet of Things (IoT)

The integration of IoT devices allows for real-time inventory tracking and automation, providing instant updates and reducing the chances of errors.

Advanced Robotics and Automation

Automated warehouses equipped with robotics can handle inventory more efficiently, speeding up order fulfillment and reducing labor costs.

Omni-Channel Integration

Seamless inventory management across multiple sales channels, including online and offline platforms, ensures consistent product availability and enhances the customer experience.

Sustainable Practices

There's a growing emphasis on eco-friendly inventory practices, such as reducing waste, optimizing energy use, and adopting sustainable packaging. These practices not only benefit the environment but also appeal to environmentally conscious consumers.

Adopting these trends will enable businesses to enhance inventory control, reduce costs, and improve customer satisfaction. Staying ahead with technological advancements ensures a competitive advantage in the dynamic market landscape.

Conclusion

Effective inventory management is crucial for the success of any business. It helps reduce costs, improve efficiency, and increase customer satisfaction. By implementing the strategies discussed, enhancing forecasting methods, and leveraging the latest technologies, businesses can optimize their inventory management practices to achieve sustained growth and competitive advantage.