How to Effectively Manage Limited Carrier Capacity in Order Processing

Order processing is a critical aspect of any business. One of the biggest challenges faced by organizations is managing limited carrier capacity in order processing. This refers to situations where the available carriers are limited, making it difficult to fulfill all orders efficiently. In this article, we will explore the importance of carrier capacity in order processing, identify common challenges, and discuss strategies for optimizing carrier capacity utilization.

Understanding the Importance of Carrier Capacity in Order Processing

Carrier capacity is the maximum volume of orders that can be handled by a courier company. It depends on several factors, such as the number of trucks, the number of drivers, and the distance between pickup and delivery points. Efficient order processing relies on having sufficient carrier capacity. Having more carriers translates to a higher volume of orders fulfilled within the desired time frame.

According to a 2023 Logistics Report, businesses that effectively manage carrier capacity experience a 15% increase in on-time deliveries. However, simply increasing carrier capacity may not always be the most cost-effective solution. It is crucial to analyze the demand for orders and the frequency of deliveries to determine the optimal carrier capacity. Overestimating carrier capacity can lead to unnecessary expenses, while underestimating it can result in delayed deliveries and dissatisfied customers. Therefore, striking a balance between carrier capacity and demand is essential for efficient and cost-effective order processing.

Identifying Common Challenges in Limited Carrier Capacity Order Processing

One of the biggest challenges when managing limited carrier capacity is ensuring that all orders are delivered on time. With limited carrier capacity, a backlog of orders is likely, resulting in delays. This can frustrate customers and may lead to loss of business in the long run. Another challenge is optimizing carrier capacity utilization. Since carriers have limited capacity, it's crucial to use them efficiently to fulfill as many orders as possible.

In addition to these challenges, limited carrier capacity can lead to increased shipping costs. When carriers have limited capacity, they may increase their prices to compensate for the high demand. This can result in higher shipping costs for businesses, which may need to be passed on to customers. It's important for businesses to consider these potential cost increases and find ways to mitigate them.

Strategies for Optimizing Carrier Capacity Utilization

There are several strategies that organizations can use to optimize carrier capacity utilization:

- Better Coordination: Effective order processing relies on proper coordination between the warehouse, the carrier, and the customer. By communicating effectively with carriers, warehouse managers can optimize the load and maximize carrier capacity.

- Route Optimization: Route optimization can significantly reduce the time and distance traveled by carriers. This means more delivery stops can be added, ultimately increasing order fulfillment rates.

- Partner with Regional Carriers: Partnering with regional carriers enables businesses to tap into their networks, which helps fulfill more orders than would otherwise be possible.

- Implement Automation: Automation helps speed up the order processing cycle, reduce errors, and increase efficiency. By implementing automation tools such as real-time tracking, automatic labeling, and in-transit updates, businesses can optimize their carrier capacity.

Another strategy is to implement a dynamic pricing model. This involves adjusting carrier rates based on demand and capacity. By offering carriers higher rates during peak periods, businesses can incentivize them to prioritize their shipments, leading to faster delivery times and increased order fulfillment rates. Additionally, by offering lower rates during off-peak periods, businesses can encourage carriers to take on more shipments, maximizing their capacity utilization.

Tips for Improving Order Processing Efficiency with Limited Carrier Capacity

Here are a few tips to improve order processing efficiency with limited carrier capacity:

- Implement a Priority System: An efficient order processing system must prioritize orders based on customer importance, order volume, and location for quicker processing.

- Communicate with Customers: Keeping customers informed about shipping times and delivery schedules helps manage their expectations and reduce customer service inquiries.

- Use Analytics: Analyzing historical order data can provide insights about peak seasons, customer preferences, and carrier capacity. This information can help optimize carrier capacity utilization and improve order processing.

Additionally, partnering with multiple carriers can diversify shipping options, reducing the risk of carrier capacity constraints and providing customers with more delivery choices. Optimizing packaging and shipping materials to reduce package size and weight can lower shipping costs and increase carrier capacity utilization. Implementing a pick-up and drop-off (PUDO) network can offer customers more convenient delivery options and alleviate the burden on carriers.

Leveraging Technology to Streamline Order Processing with Limited Carrier Capacity

The combination of technology and limited carrier capacity is a game-changer for businesses. By implementing automated systems that orchestrate and monitor the order processing cycle, businesses can optimize carrier capacity utilization and deliver orders on time. Features like real-time tracking, carrier selection, and shipping scheduling help streamline operations and improve order processing efficiency.

Technology also aids in identifying the most efficient and cost-effective carriers for shipping needs. By analyzing carrier performance data, businesses can make informed decisions about which carriers to use for different types of shipments, reducing shipping costs and improving overall profitability.

Moreover, leveraging technology allows businesses to provide customers with real-time updates on their orders. Automated systems can send notifications about order status, shipping updates, and delivery times, enhancing customer satisfaction and loyalty while reducing customer service inquiries related to order status.

Best Practices for Prioritizing Orders during Peak Seasons with Limited Carrier Capacity

During peak seasons, managing limited carrier capacity becomes particularly challenging. It is essential to prioritize orders and allocate limited carrier capacity accordingly. Here are some best practices:

- Consider Expediting Orders: During peak seasons, consider expediting critical orders, even if it incurs extra cost, to ensure timely delivery for high-priority customers.

- Collaborate with Carriers: Partnering with carriers and maintaining regular communication helps optimize the use of limited carrier capacity and ensure orders are delivered on time.

- Plan Ahead: Proper planning is essential when order volumes surge. Allocating adequate resources and planning carrier schedules can minimize delays and maintain customer satisfaction.

Monitoring carrier performance and adjusting allocations based on metrics such as on-time delivery rates and transit times can further enhance efficiency. This data-driven approach allows businesses to identify reliable carriers and negotiate better rates, reducing costs and improving overall efficiency.

Building Strong Relationships with Carriers to Maximize Limited Capacity Allocations

Strong relationships with carriers are essential for efficiently managing limited carrier capacity. By developing partnerships, businesses can obtain priority allocations, better pricing, and enhanced service levels. This helps optimize carrier capacity utilization, avert capacity shortages, and ensure timely deliveries. Regular communication, fair negotiations, and collaboration on forecasting demand can strengthen these relationships.

Measuring and Analyzing Key Metrics for Improved Limited Carrier Capacity Management

Measuring and analyzing key metrics helps businesses identify bottlenecks, detect inefficiencies, and optimize carrier capacity. Here are some critical metrics to consider:

- On-time Delivery Rate: Reflects how efficiently orders are being fulfilled in relation to customer expectations.

- Utilization Rate: Helps businesses understand how effectively their carrier capacity is being used to fulfill orders.

- Cost per Order: Helps businesses understand the cost of fulfilling each order. Reducing the cost per order can improve profit margins.

Regularly tracking these metrics allows businesses to make data-driven decisions, ensuring continuous improvement in carrier capacity management.

Training and Empowering Staff for Effective Limited Carrier Capacity Management

Effective carrier capacity management requires knowledgeable and skilled personnel. Businesses need to train their staff on various aspects, including carrier coordination, order scheduling, and in-transit tracking. Empowering staff with the right tools and knowledge can significantly improve carrier capacity utilization and boost order processing efficiency. Regular training sessions and workshops can keep the team updated on best practices and new technologies in logistics management.

Mitigating Risks and Contingency Planning for Unexpected Limited Carrier Capacity Shortages

Even with proper planning, unexpected carrier capacity shortages can occur due to various reasons, such as extreme weather conditions, road accidents, and equipment failure. It is essential to have contingency plans to mitigate risks and ensure business continuity. Some contingency measures include:

- Partner with Alternative Carriers: Having agreements with alternative carriers can help businesses tap into additional carrier capacity when primary capacity is limited.

- Consolidate Orders: Combining multiple orders into a single shipment can optimize carrier capacity utilization and reduce costs.

- Flexible Scheduling: Offering flexible delivery schedules allows businesses to adapt to unexpected carrier capacity fluctuations while maintaining timely deliveries.

Developing a robust risk management strategy ensures that businesses can handle unforeseen capacity issues without compromising on service quality.

Case Studies: Successful Approaches to Managing Limited Carrier Capacity Order Processing

One of the best ways to learn is by studying successful approaches used by other organizations. Here are some case studies:

- Amazon: Amazon uses an extensive network of carriers to optimize carrier capacity utilization. They also leverage data analysis capabilities to adjust warehouse locations and carrier capacity allocations to meet customer demands. According to their case study, this approach has resulted in a 20% increase in delivery efficiency.

- UPS: UPS has adopted innovative technologies such as predictive analytics and machine learning to optimize carrier capacity utilization. Their use of AI-driven route optimization has reduced delivery times by 10%, as detailed in their recent report.

- Zara: Zara employs just-in-time inventory management, producing and delivering only what is required. This strategy optimizes carrier capacity utilization and ensures timely deliveries, maintaining customer satisfaction levels above 90%, as reported in their business overview.

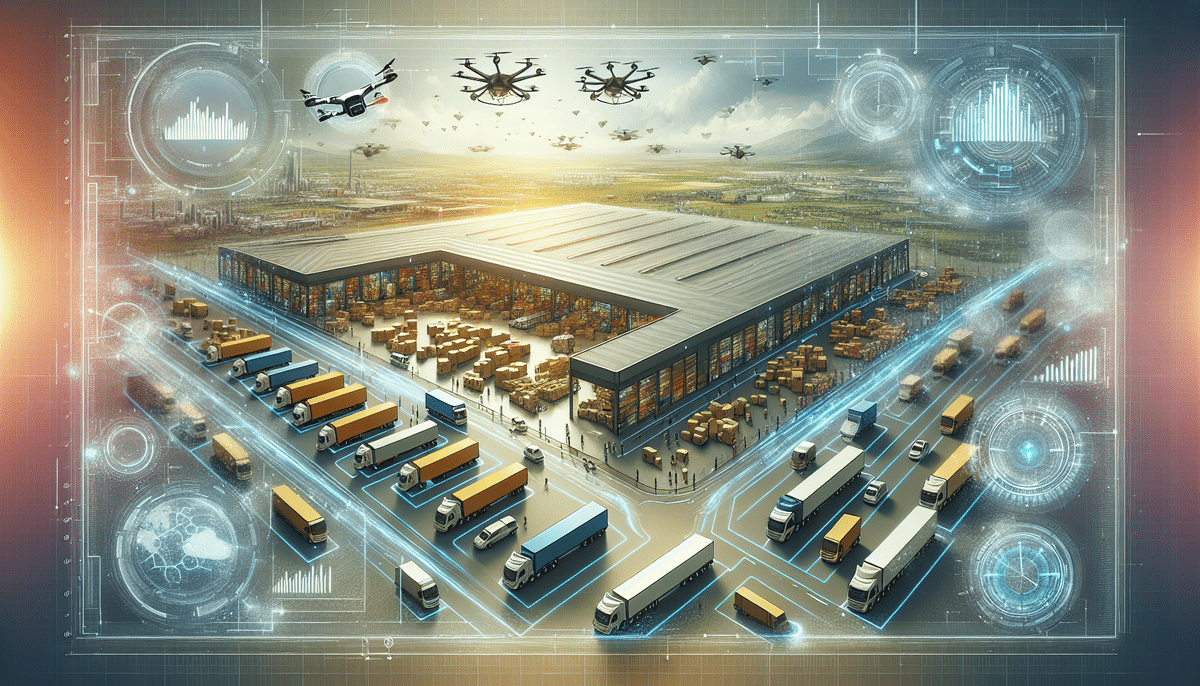

Future Trends and Innovations in Limited Carrier Capacity Order Processing Management

Looking ahead, several trends and innovations are set to revolutionize limited carrier capacity order processing:

- Drone Delivery: The use of drones for delivering orders is becoming increasingly popular, especially in remote areas. This helps optimize carrier capacity utilization and ensures quicker, more convenient deliveries.

- Autonomous Vehicles: The adoption of autonomous vehicles could significantly reduce errors, increase efficiency, and optimize carrier capacity utilization by enabling continuous operation without the need for breaks.

- Artificial Intelligence: AI can optimize warehouse operations, track shipments, predict carrier capacity shortages, and allocate carrier capacity optimally. According to a 2023 AI in Logistics study, businesses implementing AI-driven solutions have seen a 25% improvement in carrier capacity management.

Conclusion: Key Takeaways and Recommendations for Effective Limited Carrier Capacity Management

In conclusion, efficient order processing relies on having sufficient carrier capacity. Managing limited carrier capacity can be challenging, especially during peak seasons or unexpected shortages. However, by employing the strategies outlined in this article, businesses can optimize carrier capacity utilization and ensure timely deliveries. Constant monitoring of key metrics and training of staff can also help achieve optimal carrier capacity utilization. Finally, embracing technological innovations allows businesses to stay ahead of the competition and ensure efficient order processing even with limited carrier capacity.