Understanding the Importance of Effective Inventory Management

Effective inventory management is crucial for businesses that sell or produce physical goods. It enables companies to meet customer demand, minimize costs, and maximize profits. Proper inventory management ensures optimal stock levels, preventing overstocking and stockouts, which can significantly impact a company's bottom line.

According to a Investopedia report, businesses with efficient inventory management systems can reduce holding costs by up to 20% and improve order fulfillment rates by 15%. These improvements not only enhance profitability but also boost customer satisfaction and loyalty.

Common Challenges in Inventory Management and Solutions

Inaccurate Forecasting

Accurate forecasting is essential for maintaining optimal inventory levels. Inaccurate predictions can lead to overstocking or stockouts. Utilizing advanced forecasting tools and integrating real-time data can enhance prediction accuracy.

Supply Chain Disruptions

Supply chain disruptions, such as delays from suppliers or unforeseen demand spikes, can severely impact inventory levels. Developing strong relationships with multiple suppliers and implementing flexible supply chain strategies can mitigate these risks.

Vendor Management

Managing relationships with vendors is critical for ensuring a steady supply of inventory. Effective communication and performance monitoring can help maintain reliability and quality from suppliers.

Essential Elements of a Successful Inventory Management System

Accurate Tracking and Monitoring

Implementing real-time tracking systems, such as barcode scanning and RFID technology, ensures accurate monitoring of inventory levels. This accuracy is vital for making informed decisions and maintaining efficient operations.

Efficient Supply Chain Practices

Streamlining supply chain processes through automation and integration with suppliers can reduce lead times and improve overall efficiency. Techniques like Just-In-Time (JIT) inventory further enhance supply chain effectiveness.

Data Analytics for Actionable Insights

Leveraging data analytics allows businesses to identify trends, forecast demand, and optimize inventory levels. Tools like Tableau and Power BI provide robust analytics capabilities.

Choosing the Right Inventory Management Software

Selecting appropriate inventory management software is pivotal for operational efficiency. Considerations should include scalability, ease of use, feature set, and integration capabilities with existing business systems.

- QuickBooks: Ideal for small to medium-sized businesses, offering comprehensive financial and inventory management features.

- Zoho Inventory: Provides robust features with excellent integration options, suitable for growing businesses.

- TradeGecko (now QuickBooks Commerce): Offers scalable solutions for businesses expanding their inventory and sales channels.

Evaluating software based on business needs and future growth plans ensures a good fit and long-term benefits.

Best Practices for Forecasting and Demand Planning

Utilizing Historical Data

Analyzing historical sales data helps identify patterns and seasonal trends, which are essential for accurate forecasting. Tools like SAS Forecasting can enhance data analysis capabilities.

Collaborating with Stakeholders

Engaging with suppliers, sales teams, and customers provides valuable insights into market trends and demand fluctuations. This collaboration ensures forecasts are aligned with actual market conditions.

Regularly Reviewing Forecasts

Continuous monitoring and adjusting forecasts based on real-time data and market changes help maintain accuracy and responsiveness.

Streamlining the Supply Chain for Better Inventory Management

Building Strong Supplier Relationships

Developing reliable partnerships with suppliers ensures timely deliveries and quality inventory, reducing the risk of disruptions.

Implementing Technology Solutions

Adopting technologies like SAP Supply Chain Management can automate and optimize supply chain processes, enhancing visibility and efficiency.

Monitoring Key Performance Indicators (KPIs)

Tracking KPIs such as inventory turnover, order fulfillment rates, and delivery times helps identify areas for improvement and ensure the supply chain operates smoothly.

Embracing Lean Inventory Management Techniques

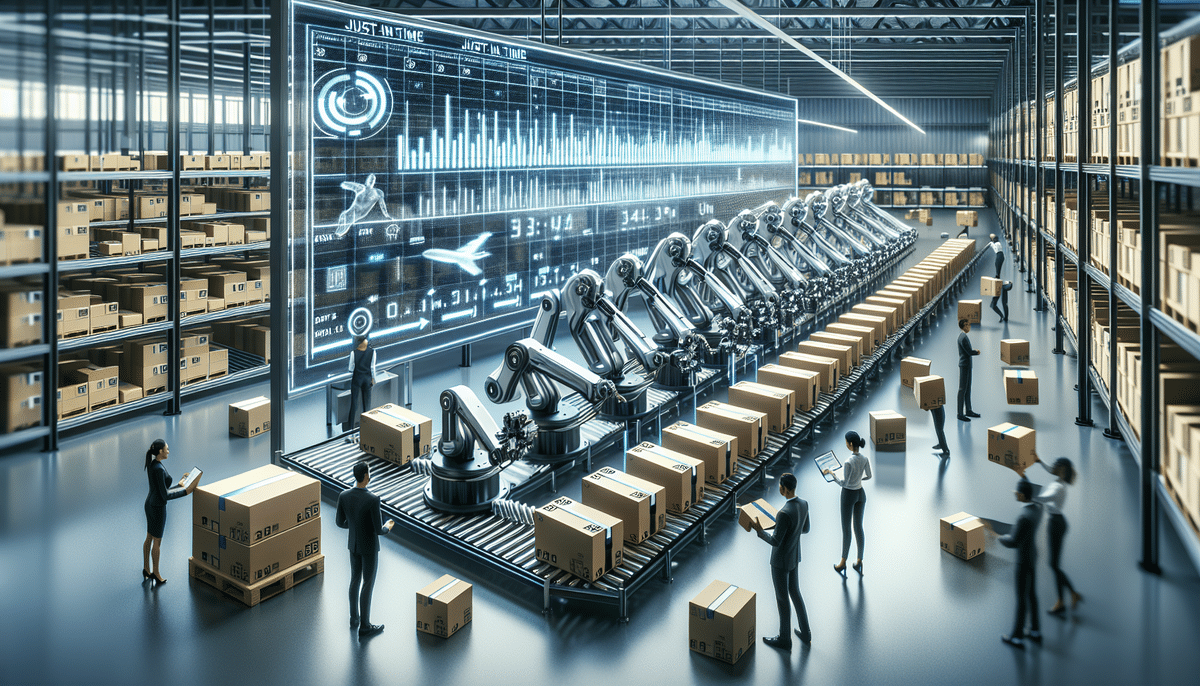

Just-In-Time (JIT) Inventory

JIT inventory involves receiving goods only as they are needed in the production process, reducing holding costs and minimizing waste. This approach requires precise coordination with suppliers and reliable demand forecasting.

Continuous Improvement Culture

Fostering a culture of continuous improvement encourages employees to identify and eliminate inefficiencies, leading to more streamlined inventory management practices.

The Role of Automation in Modern Inventory Management

Automation enhances inventory management by reducing manual errors, speeding up processes, and providing real-time data. Technologies such as IoT sensors, automated reorder systems, and AI-powered analytics are transforming how businesses manage inventory.

Measuring Success: Key Metrics in Inventory Management

- Inventory Turnover: Measures how often inventory is sold and replaced over a period.

- Carrying Costs: Calculates the total cost of holding inventory, including storage, insurance, and taxes.

- Stockout Rate: Tracks the frequency of inventory being unavailable when needed.

- Lead Time: The time taken from placing an order with a supplier to receiving the goods.

Monitoring these metrics helps businesses assess the effectiveness of their inventory management strategies and identify areas for improvement.

Developing a Comprehensive Inventory Management Plan

A well-structured inventory management plan outlines policies, procedures, and goals tailored to the business's specific needs. Key components include:

- Inventory Policies: Guidelines on ordering, stock levels, and handling excess inventory.

- Goal Setting: Defining clear objectives such as reducing carrying costs or improving turnover rates.

- Continuous Evaluation: Regularly reviewing and adjusting the plan based on performance metrics and changing business conditions.

Leveraging Data Analytics to Optimize Inventory Strategy

Data analytics plays a vital role in refining inventory management strategies. By analyzing sales trends, customer behavior, and supply chain performance, businesses can make informed decisions to optimize inventory levels and improve efficiency.

Tools like Google Analytics and Tableau enable businesses to visualize data and uncover actionable insights.

Enhancing Collaboration Across Departments

Effective inventory management requires seamless collaboration between departments such as purchasing, sales, and logistics. Implementing integrated systems and fostering open communication channels ensures that all teams are aligned and working towards common inventory goals.

The Future of Inventory Management: Emerging Trends and Technologies

Internet of Things (IoT)

IoT devices provide real-time tracking of inventory, offering greater visibility and control over stock levels. This technology enables proactive management and quick response to inventory changes.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms enhance demand forecasting, optimize stock levels, and automate routine tasks, leading to more efficient inventory management.

Blockchain Technology

Blockchain offers secure and transparent tracking of inventory movements, enhancing trust and reducing the risk of fraud in the supply chain.

Staying abreast of these emerging technologies ensures that businesses can leverage the latest advancements to maintain a competitive edge in inventory management.

Conclusion

Effective inventory management is essential for business success, impacting profitability, customer satisfaction, and operational efficiency. By implementing best practices, leveraging advanced technologies, and fostering cross-departmental collaboration, businesses can optimize their inventory processes and achieve long-term success in a dynamic marketplace.