Enhancing Your E-Commerce Logistics Receiving Process for Optimal Efficiency

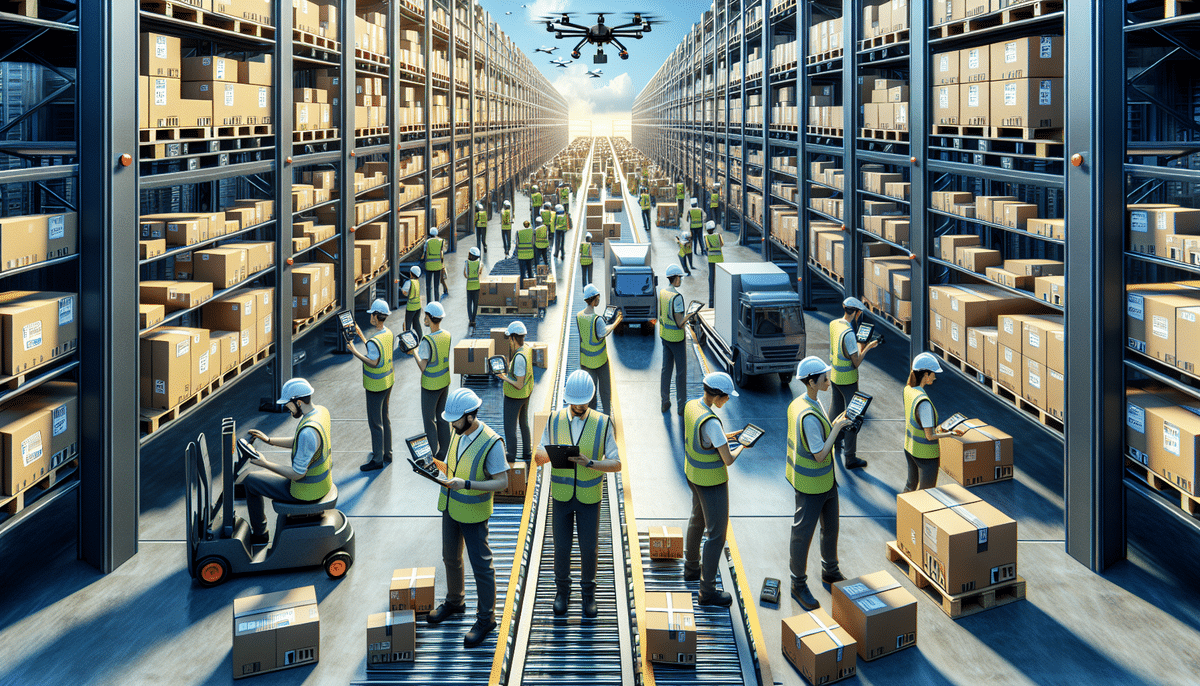

In the competitive world of e-commerce, an efficient logistics receiving process is paramount for ensuring smooth operations and customer satisfaction. This critical phase involves receiving, inspecting, and storing inbound shipments, setting the foundation for accurate inventory management and timely order fulfillment.

Understanding the E-Commerce Receiving Process

Overview of the Receiving Process

The receiving process in e-commerce encompasses several steps: inspecting incoming shipments, verifying inventory against purchase orders, labeling, and organizing products within the warehouse. A streamlined process ensures that inventory is accurate and readily available for sale.

The Importance of Accuracy and Speed

Accuracy in the receiving process prevents inventory discrepancies, which can lead to lost sales and customer dissatisfaction. Speed is equally crucial, as timely processing of inventory keeps up with customer demand and maintains competitiveness. According to a Shopify report, efficient inventory management can reduce holding costs by up to 30%.

Common Challenges in E-Commerce Receiving

Handling Multiple Shipments and Suppliers

E-commerce businesses often receive shipments from various suppliers in multiple packages. This complexity can make verification time-consuming and increase the likelihood of errors, leading to inaccurate inventory counts and potential stock-outs.

Inadequate Storage Facilities

Insufficient or poorly organized storage areas can result in damaged or lost inventory, causing delays in order fulfillment and increased operational costs. Proper storage solutions are essential to maintain product integrity and streamline warehouse operations.

Managing Returns Efficiently

Returns add another layer of complexity to the receiving process. Efficiently handling returns requires additional resources and meticulous tracking to prevent inventory discrepancies and ensure returned items are reintegrated into inventory accurately.

Implementing a robust returns management system is crucial for maintaining inventory accuracy and minimizing the impact of returns on overall operations.

Key Components of an Effective Receiving Process

Establishing a Dedicated Receiving Area

Setting up a designated receiving area with adequate space is fundamental. This area should be equipped with the necessary tools and technology to handle incoming shipments efficiently.

Implementing Quality Control Measures

Quality control is vital for verifying that received items meet order specifications. Conducting visual inspections and testing product functionality can help identify defects or discrepancies early in the process.

Utilizing Technology for Inventory Management

Advanced inventory management systems, such as barcode scanners and RFID technology, automate tracking and reduce human errors. According to a Forbes article, businesses that adopt these technologies can reduce processing time by up to 40%.

Enhancing the Receiving Process with Technology

Automation and Digital Tools

Automation tools like automated data entry and cloud-based inventory systems streamline the receiving process. These technologies facilitate real-time inventory tracking, enabling quicker decision-making and more accurate stock management.

Integrating Inventory Management Systems

Implementing comprehensive inventory management systems can centralize data, making it easier to monitor stock levels, track shipments, and manage inventory across multiple locations. This integration enhances overall operational efficiency and accuracy.

Best Practices for Inventory Management

Organizing the Warehouse Efficiently

An organized warehouse is crucial for efficient inventory management. Using barcodes, storage bins, and clearly labeled sections helps in easy retrieval and accurate tracking of products.

Implementing First-In, First-Out (FIFO)

The FIFO method ensures that older inventory is sold first, reducing the risk of stock obsolescence and minimizing holding costs. This practice is especially important for perishable goods and items with expiration dates.

Regular Inventory Audits

Conducting regular cycle counts and physical inventory checks helps maintain accurate inventory records. These audits identify discrepancies early, allowing for timely corrections and preventing larger inventory issues.

Staffing, Training, and Standard Operating Procedures

Hiring the Right Team

Employing skilled staff with experience in warehouse management and e-commerce logistics is essential. The right team members bring attention to detail, organizational skills, and the ability to handle high-pressure situations effectively.

Comprehensive Training Programs

Ongoing training ensures that employees are up-to-date with the latest processes and technologies. Training should cover the use of receiving equipment, inventory management systems, quality control procedures, and safety protocols.

Establishing Standard Operating Procedures (SOPs)

Developing clear SOPs standardizes the receiving process, ensuring consistency and reducing the likelihood of errors. SOPs should outline step-by-step instructions for receiving tasks, defined roles, and guidelines for handling discrepancies.

Strategies to Reduce Errors and Improve Accuracy

Implementing Double-Check Systems

Having multiple employees verify the same tasks can significantly reduce errors. Double-check systems ensure that discrepancies are caught and corrected before they impact inventory records.

Utilizing Quality Control Checklists

Quality control checklists provide a structured approach to inspecting received inventory. These checklists ensure that all necessary steps are followed, maintaining high standards of accuracy and quality.

Integrating Automated Systems

Automated systems minimize human error by handling repetitive tasks such as data entry and inventory updates. This integration enhances the overall accuracy and efficiency of the receiving process.

According to a Warehouse Management System, implementing these strategies can improve inventory accuracy by up to 99.5%.

Leveraging Data Analytics for Performance Monitoring

Tracking Key Performance Indicators (KPIs)

Monitoring KPIs such as receiving time per shipment, accuracy rates, and inventory turnover rates provides insights into the efficiency of the receiving process. These metrics help identify areas for improvement and track progress over time.

Identifying Bottlenecks and Performance Issues

Data analytics can pinpoint specific stages in the receiving process that cause delays or errors. Addressing these bottlenecks leads to smoother operations and enhanced overall performance.

Making Data-Driven Decisions

Utilizing data analytics allows businesses to make informed decisions that optimize the receiving process. By analyzing performance data, companies can implement targeted strategies to improve efficiency and reduce costs.

Collaboration with Suppliers and Carriers

Establishing Clear Communication Channels

Effective communication with suppliers and carriers is essential for coordinating deliveries and resolving issues promptly. Clear communication helps ensure that shipments arrive on time and meet quality standards.

Coordinating Delivery Schedules

Aligning delivery schedules with business needs minimizes wait times and reduces the risk of delays in the receiving process. Collaborative planning with suppliers and carriers enhances overall supply chain efficiency.

Negotiating Favorable Shipping Terms

Negotiating better shipping rates and terms with carriers can lead to cost savings and more reliable delivery services. Favorable terms also contribute to smoother operations and improved supplier relationships.

Effective collaboration can reduce wait times, lower shipping costs, and enhance the reliability of your receiving process.

Conclusion: The Benefits of Optimizing Your E-Commerce Logistics Receiving Process

Optimizing the receiving process in your e-commerce logistics is crucial for maintaining inventory accuracy, enhancing order fulfillment, and boosting customer satisfaction. By implementing efficient workflows, leveraging advanced technologies, and investing in staff training, your business can minimize errors and improve overall warehouse performance.

Adopting strategies such as quality control, data analytics, and strong collaboration with suppliers and carriers empowers your e-commerce business to manage inventory effectively, reduce operational costs, and handle peak shipping periods with ease. These improvements not only lead to satisfied customers but also position your business as a leader in the competitive e-commerce market.