Improving Your Inventory Position for Maximum Profitability

Maximizing profitability hinges on optimizing your inventory position. Maintaining optimal inventory levels ensures you have the right products in the right quantities, reducing costs associated with excess inventory and stockouts. This comprehensive guide explores key strategies to enhance your inventory position, including identifying slow-moving and dead stock, accurate forecasting, implementing an effective inventory management system, and leveraging modern technologies to streamline operations.

Maintaining Optimal Inventory Levels

Inventory management is a critical aspect of any business, directly impacting customer satisfaction and profitability. Maintaining optimal inventory levels strikes a balance between meeting customer demand and minimizing carrying costs. According to a 2023 study by the Supply Chain Digital, businesses that achieve optimal inventory levels can reduce carrying costs by up to 20% and increase customer satisfaction by 15%.

Benefits of Optimal Inventory Levels

- Reduced Risk of Stockouts: Prevents loss of sales and maintains customer trust.

- Lower Inventory Carrying Costs: Minimizes expenses related to storage, insurance, and obsolescence.

- Improved Operational Efficiency: Enhances production planning, supply chain management, and warehouse utilization.

External factors such as seasonality, market trends, and supplier lead times influence the delicate balance of inventory levels. By monitoring these factors, businesses can adjust their inventory strategies to better align with current market demands.

Key Strategies for Effective Inventory Management

Understanding Your Inventory Turnover Ratio

The inventory turnover ratio is a pivotal metric for assessing the efficiency of your inventory management system. It measures how often inventory is sold and replaced over a specific period. A high turnover ratio signifies strong sales performance and effective inventory management.

Conversely, a low turnover ratio may indicate overstocking or obsolescence, leading to increased carrying costs. According to recent data, the average inventory turnover ratio across various industries is approximately 5 times per year, but this can vary significantly depending on the sector.

Identifying Slow-Moving and Dead Stock

Effectively managing slow-moving and dead stock is essential for maintaining optimal inventory levels. Excess inventory not only ties up capital but also increases storage costs and the risk of obsolescence.

Methods to Identify Slow-Moving and Dead Stock

- Sales Data Analysis: Examine sales trends to identify products with declining sales.

- Regular Physical Counts: Conduct periodic inventory audits to spot stagnant items.

Once identified, strategies such as discounting, bundling, or discontinuing these products can help clear space for more profitable items. For instance, a 2022 study published in the Journal of Inventory Management found that businesses effectively reduced dead stock by 30% through targeted discounting strategies.

Implementing an Effective Inventory Management System

An effective inventory management system is crucial for optimizing your inventory position. Key features should include:

- Real-time tracking of stock levels

- Inventory forecasting capabilities

- Automation of inventory replenishment

- Enhanced order management

Modern systems can integrate with other business processes, providing a seamless flow of information that reduces the need for manual tracking and minimizes errors. Additionally, advanced inventory management systems can utilize artificial intelligence to predict demand patterns, further enhancing accuracy and efficiency.

Role of Forecasting in Inventory Management

Accurate demand forecasting is essential for maintaining optimal inventory levels. By predicting future demand, businesses can better plan their inventory orders, reducing the likelihood of shortages or excess stock.

Forecasting Methods

- Qualitative Methods: Rely on expert opinions, customer feedback, and market analysis.

- Quantitative Methods: Utilize statistical models and historical sales data to predict future demand.

Implementing machine learning algorithms can enhance forecasting accuracy by identifying complex patterns and trends that traditional methods may overlook. According to a 2023 report by Business Insider, businesses that adopt AI-driven forecasting experience a 25% improvement in forecast accuracy.

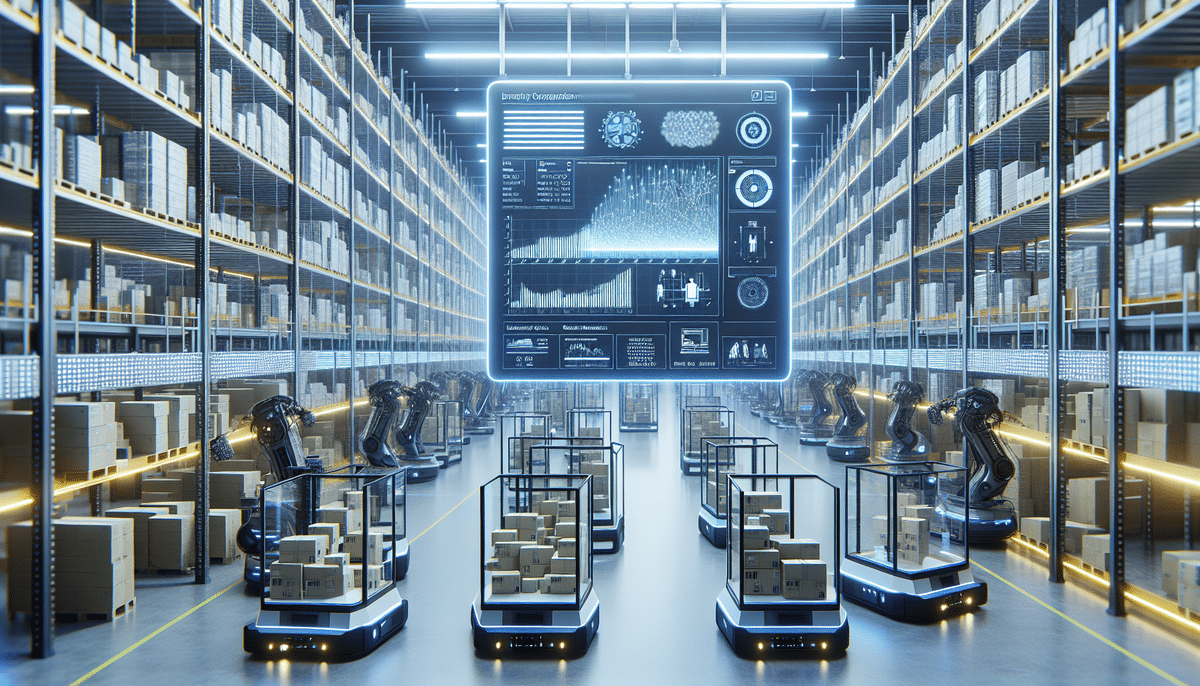

Leveraging Technology for Inventory Optimization

Improving Supply Chain Visibility

Enhanced supply chain visibility is vital for effective inventory management. Increased transparency enables businesses to monitor inventory levels in real-time, reducing the risk of stockouts and overstocking.

Benefits of Improved Supply Chain Visibility

- Faster decision-making with accurate data

- Identification of bottlenecks and inefficiencies

- Enhanced collaboration with suppliers and partners

Implementing technologies such as Internet of Things (IoT) devices and blockchain can further enhance supply chain transparency. A 2023 study by McKinsey & Company highlights that businesses using IoT for supply chain visibility report a 20% reduction in lead times and a 15% decrease in inventory costs.

Leveraging Advanced Technologies

Modern technologies play a pivotal role in optimizing inventory management. From advanced software solutions to automation tools, leveraging technology can significantly enhance your inventory position.

Key Technologies for Inventory Management

- Inventory Management Software: Provides real-time tracking, forecasting, and reporting capabilities.

- Cloud-Based Solutions: Offer scalability, accessibility, and integration with other business systems.

- Artificial Intelligence and Machine Learning: Enhance demand forecasting and inventory optimization through predictive analytics.

Adopting these technologies can lead to more informed decision-making, improved accuracy in inventory tracking, and greater overall efficiency. A 2023 survey by Gartner found that 85% of businesses leveraging AI in inventory management saw significant improvements in operational efficiency.

Managing Inventory Challenges

The Impact of Seasonality on Inventory Management

Seasonality can significantly influence inventory levels, making it essential to incorporate seasonal trends into your inventory management strategy. Proper planning ensures that you can meet fluctuating demand without overstocking.

Strategies to Manage Seasonality

- Analyze Historical Sales Data: Identify seasonal patterns and adjust inventory levels accordingly.

- Flexible Supply Chain: Develop relationships with suppliers who can accommodate fluctuations in order volumes.

- Promotional Planning: Schedule promotions and marketing campaigns to align with seasonal demand spikes.

Implementing a robust forecasting system that accounts for seasonality can help businesses maintain balanced inventory levels year-round, reducing the risks associated with seasonal demand fluctuations.

Dealing with Overstocked Items: Strategies and Solutions

Managing overstocked items is crucial to prevent excess inventory from becoming a financial burden. Effective strategies can help recover value from overstocked inventory while maintaining optimal stock levels.

Strategies for Managing Overstocked Items

- Price Discounting: Offer discounts to quickly sell excess inventory.

- Diversify Sales Channels: Utilize multiple sales platforms to reach a broader audience.

- Bundle Products: Combine overstocked items with popular products to increase sales.

Solutions for Overstocked Items

- Consignment Sales: Partner with retailers to sell excess inventory without upfront costs.

- Liquidation: Sell inventory through liquidators at reduced prices.

- Recycling: Recycle or repurpose unsellable items to minimize waste.

Implementing a structured overstock management plan can help mitigate the financial impact of excess inventory and ensure resources are allocated to more profitable areas.

Managing Perishable and Expiring Items

Inventory management for perishable and expiring items requires meticulous planning and precise execution to minimize losses and maximize profitability.

Best Practices for Managing Perishable and Expiring Items

- Set Accurate Shelf Lives and Expiry Dates: Clearly label products with accurate expiration information.

- Implement First-Expire, First-Out (FEFO) System: Ensure that older inventory is sold before newer stock.

- Invest in Temperature-Controlled Storage: Maintain appropriate storage conditions to extend product shelf life.

- Use Inventory Management Software: Track expiration dates and automate alerts for near-expiry items.

According to a 2023 report by the Nature, effective management of perishable inventory can reduce waste by up to 40% and improve overall profitability by ensuring that products reach customers in optimal condition.

Balancing Costs and Customer Demand in Inventory Planning

Balancing costs and customer demand is a fundamental aspect of inventory planning. Striking this balance ensures that you meet customer needs without incurring unnecessary costs.

Key Considerations for Balancing Costs and Demand

- Accurate Forecasting: Use reliable forecasting methods to predict demand and adjust inventory levels accordingly.

- Prioritize High-Demand Items: Ensure fast-moving products are always in stock to maximize sales.

- Optimize Order Quantities: Use EOQ models to determine the most cost-effective order sizes.

Implementing a robust inventory management system that provides real-time data and analytics enables businesses to dynamically adjust their inventory plans in response to changing customer demands, ensuring cost-efficiency and high customer satisfaction.

Streamlining Warehouse Operations for Improved Efficiency

Efficient warehouse operations are integral to effective inventory management. Streamlining processes can reduce lead times, lower holding costs, and improve order fulfillment accuracy.

Techniques to Streamline Warehouse Operations

- Implement Warehouse Management Systems (WMS): Automate and optimize warehouse workflows.

- Adopt Barcode Scanning: Enhance inventory tracking accuracy and speed.

- Optimize Warehouse Layout: Design layouts that minimize movement and improve picking efficiency.

For example, integrating a Warehouse Management System (WMS) can lead to a 30% increase in picking efficiency and a 25% reduction in order processing errors, according to recent industry research.

Conclusion

Enhancing your inventory position for maximum profitability involves a multi-faceted approach encompassing strategic inventory management practices. From identifying and managing slow-moving stock to leveraging advanced forecasting techniques and modern technologies, each aspect plays a vital role in maintaining optimal inventory levels. By implementing these strategies, businesses can reduce costs, improve operational efficiency, and drive sustainable long-term growth.

For more insights and solutions on inventory management, visit ShipScience.