The Importance of Accurate Inventory Records

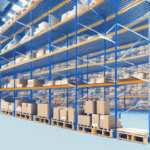

Accurate inventory records are fundamental to the success of any business in today’s competitive marketplace. According to the National Retail Federation, poor inventory management can lead to a significant loss in revenue, with some businesses losing up to 10% of their sales due to inventory inaccuracies. Maintaining precise records helps you track stock levels, anticipate reorder needs, and prevent stockouts that result in lost sales and dissatisfied customers.

Furthermore, accurate inventory records enable you to identify top-performing products, minimize costs associated with overstocking, and make informed purchasing decisions. They also play a crucial role in detecting and preventing internal theft or fraud by regularly reconciling physical stock with recorded inventory levels, thereby safeguarding your business’s integrity and profitability.

Key Elements of Effective Inventory Management

Proper Planning and Forecasting

Effective inventory management begins with meticulous planning and forecasting. Understanding your inventory turnover rates, lead times, and seasonal demand fluctuations allows you to maintain optimal stock levels. According to a study by Harvard Business Review, businesses that excel in forecasting can reduce excess inventory by up to 25%.

Robust Inventory Management Systems

Implementing a reliable inventory management system can automate tasks such as tracking stock levels, generating purchase orders, and forecasting demand. This automation not only saves time but also reduces human error, ensuring greater accuracy in your inventory records.

Reliable Supplier Network

Establishing strong relationships with your suppliers is essential for timely deliveries and maintaining consistent stock levels. A dependable supplier network helps prevent stockouts and overstocking, which can lead to increased operational costs and lost sales opportunities. Additionally, having backup suppliers can provide resilience against supply chain disruptions.

Inventory Control Methods

ABC Analysis

ABC analysis categorizes inventory into three classes based on their importance:

- A-items: High-value products with low sales frequency.

- B-items: Moderate value and sales frequency.

- C-items: Low-value products with high sales frequency.

>This method helps prioritize management efforts and allocate resources effectively.

Just-in-Time (JIT) Inventory

The JIT inventory method minimizes inventory holding costs by receiving goods only as they are needed in the production process. This approach reduces waste and increases efficiency but requires accurate demand forecasting and reliable suppliers.

Economic Order Quantity (EOQ)

EOQ calculates the optimal order quantity that minimizes the total costs of inventory, including ordering and holding costs. This method helps maintain balance between overstocking and stockouts.

Choosing the Right Inventory System

Assessing Your Business Needs

When selecting an inventory management system, consider factors such as the size of your business, the complexity of your supply chain, and your specific operational requirements. A solution that offers scalability and customization can adapt to your growing business needs.

Integration and Usability

Ensure that the inventory system integrates seamlessly with your existing software, such as accounting and e-commerce platforms. User-friendly interfaces and comprehensive training resources are also critical for successful implementation.

Vendor Support and Reliability

Choose a vendor that provides excellent customer support and has a proven track record of reliability. According to Gartner, companies with strong vendor support report higher user satisfaction and system effectiveness.

Best Practices for Recording and Tracking Inventory

Unique Identification and Labeling

Label each inventory item with a unique identifier, such as a barcode or RFID tag. This practice enhances tracking accuracy and simplifies the process of locating and managing stock items.

Regular Cycle Counts

Conducting regular cycle counts ensures that inventory records match physical stock. This proactive approach helps identify discrepancies early and maintains the integrity of your inventory data.

Dedicated Inventory Management Team

Assign a dedicated team to oversee inventory management tasks. A specialized team can focus on maintaining accurate records, performing audits, and implementing inventory strategies effectively.

Leveraging Technology for Inventory Management

Advanced Inventory Management Software

Modern inventory management software offers features like real-time tracking, automated reordering, and predictive analytics. Tools like TradeGecko and Oracle Inventory Management provide comprehensive solutions to streamline your inventory processes.

Barcode and RFID Technology

Implementing barcode and RFID technology enhances the accuracy and efficiency of inventory tracking. These technologies reduce manual errors and provide real-time visibility into stock levels across multiple locations.

Cloud-Based Solutions

Cloud-based inventory systems offer scalable and flexible solutions that can be accessed from anywhere. They facilitate better collaboration, data synchronization, and disaster recovery compared to traditional on-premises systems.

Training Employees for Effective Inventory Management

Comprehensive Training Programs

Invest in comprehensive training programs to ensure that your employees understand inventory management principles and the proper use of inventory systems. Well-trained employees are more likely to maintain accurate records and follow best practices.

Standard Operating Procedures (SOPs)

Develop and implement clear SOPs for all inventory management tasks. SOPs provide consistency and ensure that all team members follow the same processes, reducing the likelihood of errors.

Continuous Learning and Improvement

Encourage continuous learning and regularly update training materials to reflect changes in inventory management practices and technologies. Keeping your team informed fosters a culture of continuous improvement and adaptability.

Analyzing and Optimizing Inventory Performance

Regular Inventory Audits

Conduct regular inventory audits to identify and rectify discrepancies in your inventory records. Audits help ensure data accuracy and provide insights into the effectiveness of your inventory management practices.

Demand Forecasting

Utilize historical sales data and market trends to forecast future demand. Accurate demand forecasting allows you to adjust inventory levels proactively, preventing stockouts and overstocking scenarios.

Performance Metrics

Track key performance metrics such as inventory turnover ratio, carrying costs, and order accuracy. Monitoring these metrics helps you identify areas for improvement and optimize your inventory management strategies.

Conclusion

Maintaining accurate inventory records is essential for optimizing operations, reducing costs, and enhancing customer satisfaction. By implementing effective inventory management practices, leveraging the right technology, and continuously analyzing performance, businesses can achieve a streamlined inventory process that supports long-term success.