Importance of Accurate Box Measurements

Accurately measuring the dimensions of a box is essential in various industries, including shipping, storage, and inventory management. Precise measurements ensure optimal use of space, cost-effective shipping, and the safety of the box's contents. According to a report by Statista, businesses that implement accurate measurement practices can reduce shipping costs by up to 15%.

Incorrect measurements can lead to wasted space, increased shipping costs, and potential damage to items. For instance, an overestimated box size may result in higher shipping fees, while an underestimated size could cause items to shift and break during transit.

Essential Tools for Measuring Boxes

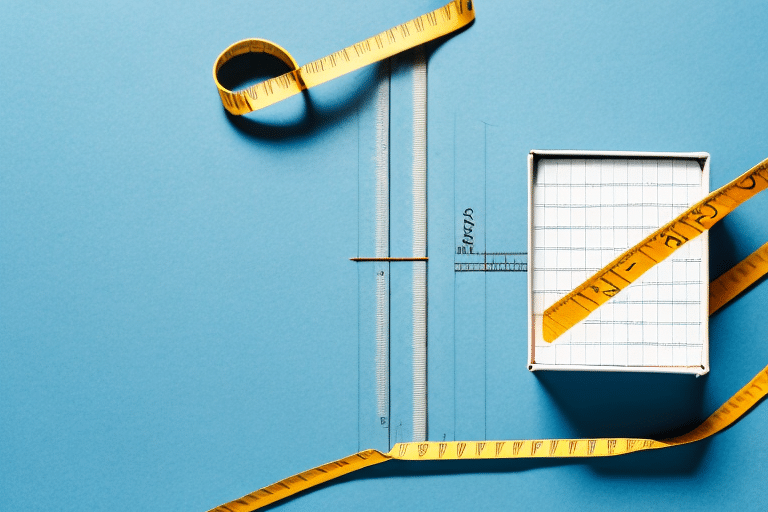

Having the right tools is crucial for obtaining accurate box dimensions. The following tools are recommended:

- Measuring Tape: A flexible tape measure allows for easy measurement of various dimensions.

- Ruler: Useful for smaller or more detailed measurements.

- Scale: Helps determine the weight capacity of the box.

- Notebook or Spreadsheet: Essential for recording measurements systematically.

For large-scale operations, digital measuring tools and automated systems can enhance efficiency and accuracy.

Step-by-Step Guide to Measuring Box Dimensions

Measuring Length

To measure the length of a box, place it on a flat surface and use a measuring tape to determine the longest side. Ensure the tape is flush against the edge for an accurate measurement.

Measuring Width

Measure the shortest side of the box by placing it on a flat surface and using a measuring tape. The width is typically perpendicular to the length.

Measuring Height

Stand the box upright and measure from the base to the top. Accurate height measurement is crucial for shipping, as many carriers have height restrictions.

Common Mistakes and Troubleshooting

Avoiding Measurement Errors

Common mistakes include not measuring from edge to edge, failing to account for protrusions, and ignoring the thickness of box materials. Using a straightedge can help maintain measurement accuracy.

Troubleshooting Irregular Shapes

For boxes with irregular shapes or rounded corners, break down the measurement process into simpler geometric shapes. This approach ensures each section is measured accurately before combining them for the total dimensions.

Calculating Volume and Weight Capacity

Volume Calculation

Volume is calculated by multiplying the length, width, and height of the box (Volume = Length × Width × Height). This metric helps determine how much space the box occupies and its suitability for storage or shipping.

Determining Weight Capacity

The weight capacity of a box depends on its volume and the strength of the material. Consult industry guidelines, such as those from the International Safe Transit Association (ISTA), to ensure boxes can safely handle the intended weight.

Best Practices and Technology for Measuring and Recording Dimensions

Best Practices

- Double-Check Measurements: Always verify measurements to prevent errors.

- Use Consistent Units: Stick to one unit of measurement (e.g., inches or centimeters) for consistency.

- Proper Labeling: Clearly label each box with its dimensions for easy identification and handling.

- Record-Keeping: Maintain detailed records of all measurements to streamline inventory management.

Leveraging Technology

Modern technology offers tools such as digital measuring devices and mobile apps that enhance measurement accuracy and efficiency. For example, apps like MeasureKit utilize smartphone sensors to provide precise measurements quickly.

Enhancing Shipping and Storage Efficiency through Accurate Measurements

Accurate box dimensions contribute significantly to optimizing shipping and storage processes. By knowing the exact size of each box, businesses can:

- Maximize Storage Space: Efficiently arrange boxes to utilize available space fully.

- Reduce Shipping Costs: Choose the most cost-effective shipping options based on box dimensions.

- Improve Inventory Management: Easily track and locate boxes within storage facilities.

Implementing precise measurement practices can lead to significant cost savings and operational efficiencies. For more insights on optimizing shipping processes, refer to the Logistics Management website.