Key Factors in Selecting the Right Warehouse

Before selecting a warehouse, it's essential to evaluate several key factors that will significantly impact your business operations. These factors include:

- Location

- Storage Needs

- Type of Warehouse

- Facility Condition

- Size

- Technology

- Lease Terms and Legal Requirements

- Inventory Management

- Safety and Security

- Operational Efficiency

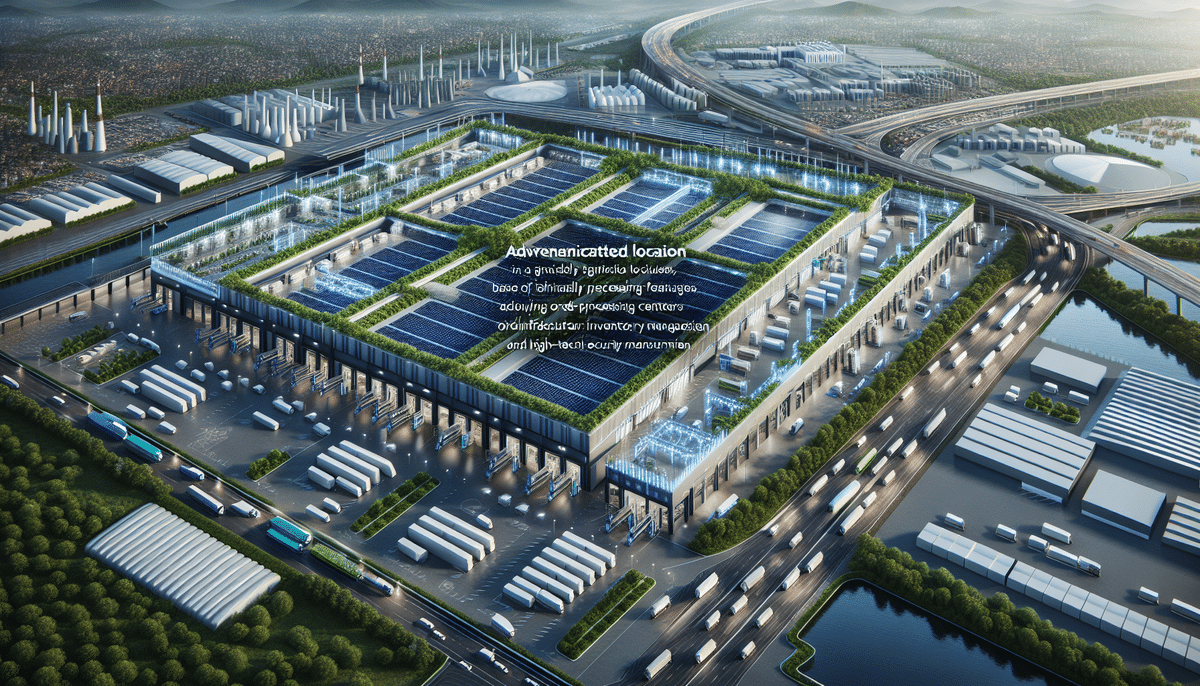

Location

Accessibility is paramount when selecting a warehouse location. Ensure that the warehouse is easily accessible to your suppliers, customers, and employees. Proximity to major highways, ports, and airports can help reduce transportation costs and improve delivery times.

Additionally, consider the local climate and potential weather-related disruptions. For businesses dealing with temperature-sensitive goods, ensure that the location can provide the necessary climate control.

Storage Needs

Assess your current and future storage requirements. Determine the types of goods you need to store, such as perishable items requiring temperature control or bulky items needing more space. Understanding your storage needs will help in selecting a warehouse that can accommodate your inventory efficiently.

Type of Warehouse

There are various types of warehouses, each with unique features suited for different business needs:

- Public Warehouses: Offer storage space for multiple tenants, providing flexibility for small businesses.

- Private Warehouses: Owned and operated by a single company, offering more control over inventory.

- Distribution Centers: Designed for the efficient movement of goods, often located near transportation hubs.

- Cold Storage Warehouses: Equipped for storing perishable items with specialized refrigeration systems.

- Fulfillment Centers: Focused on processing and shipping orders directly to customers.

Facility Condition

The condition of the warehouse affects both operations and costs. Conduct a thorough inspection of the warehouse's structure, including the roof, foundation, walls, and flooring. Ensure that the electrical and plumbing systems are in good working order and that security measures are robust.

Technology

Modern warehouses leverage technology to enhance efficiency. Consider warehouses equipped with inventory management systems, barcode scanners, RFID technology, and automation tools. These technologies enable real-time tracking of inventory, reduce errors, and streamline operations.

Understanding Warehouse Types and Their Features

Choosing the right type of warehouse is crucial for meeting your specific business needs. Here are some common types of warehouses and their features:

- Public Warehouses: Ideal for businesses needing flexible storage options without the commitment of ownership.

- Private Warehouses: Suitable for larger companies requiring dedicated storage space and greater control over operations.

- Distribution Centers: Designed for handling large volumes of goods, often featuring advanced sorting and distribution systems.

- Cold Storage Warehouses: Essential for businesses dealing with perishable items, offering temperature-controlled environments.

- Fulfillment Centers: Focused on e-commerce businesses, facilitating quick and efficient order processing and shipping.

Each warehouse type serves different purposes, so it's important to align your choice with your business operations and goals.

Evaluating Warehouse Conditions and Size

Assessing Facility Condition

A well-maintained warehouse ensures smooth operations and minimizes unexpected disruptions. Key areas to inspect include:

- Roof and Foundation

- Walls and Flooring

- Electrical and Plumbing Systems

- Security Measures

- Heating and Cooling Systems

Ensuring the facility is in good condition can prevent operational delays and additional maintenance costs.

Determining the Right Size

Selecting an appropriately sized warehouse is vital for operational efficiency and cost management. Consider the following when determining warehouse size:

- Your current inventory levels

- Expected future inventory growth

- Expansion plans over the next few years

- Your forecasting accuracy

Additionally, the layout and type of products stored can influence the required space. For example, businesses handling perishable goods might need more space for climate-controlled storage.

Leveraging Technology for Efficient Warehouse Management

Integrating technology into warehouse operations can significantly enhance efficiency and accuracy. Key technologies to consider include:

- Real-time inventory tracking using barcode scanners and RFID technology

- Automated systems for picking and packing

- Warehouse Management Systems (WMS) that streamline inventory control and order fulfillment

- Automated storage and retrieval systems to optimize space utilization

Implementing these technologies can lead to increased productivity, reduced labor costs, and improved accuracy in inventory management.

Negotiating Lease Terms and Legal Requirements

Negotiating Lease Terms

Lease agreements play a significant role in the overall cost and flexibility of your warehouse operations. When negotiating lease terms, consider the following:

- Lease Length: Ensure the lease duration aligns with your business plans.

- Monthly Rent and Escalations: Understand rent structures and any potential increases over time.

- Maintenance and Repair Responsibilities: Clarify which party is responsible for upkeep and repairs.

- Security Deposit and Insurance Requirements: Ensure you are aware of the financial commitments required.

- Renewal Options and Termination Clauses: Negotiate terms that allow flexibility for future changes.

Refer to the latest CBRE US Industrial Outlook for current market lease rates and trends.

Understanding Legal Requirements

Operating a warehouse involves complying with various legal regulations, including:

- Zoning Laws: Ensure the warehouse is located in an area zoned for industrial use.

- Labor Laws: Comply with regulations regarding employee rights and working conditions.

- Environmental Regulations: Adhere to laws related to waste management, emissions, and sustainability.

- Safety Requirements: Implement safety protocols as per guidelines from organizations like the Occupational Safety and Health Administration (OSHA).

Understanding these requirements helps in avoiding legal issues and ensuring smooth operations.

Effective Inventory and Safety Management

Managing Inventory

Efficient inventory management is crucial for maintaining optimal stock levels and ensuring timely order fulfillment. Here are some best practices:

- Organize inventory strategically for easier picking and packing

- Create an inventory management system that tracks inventory levels, order fulfillment, and cycle times

- Implement an effective routing system for receiving and shipping inventory

- Ensure your employees are trained on inventory management best practices

Leverage technology such as Warehouse Management Systems (WMS) to automate and streamline inventory processes.

Ensuring Safety and Security

Maintaining a safe and secure warehouse environment is essential for protecting your assets and employees. Implement the following measures:

- Install security cameras, alarms, and access controls

- Create safety protocols for employees and visitors

- Regularly inspect equipment and facilities to identify potential safety issues

- Implement a reporting and incident response system for injuries or accidents

According to the Centers for Disease Control and Prevention (CDC), comprehensive safety programs can significantly reduce workplace injuries in warehouse settings.

Enhancing Warehouse Operations and Efficiency

Cost-Effective Improvements

Enhancing your warehouse operations doesn't always require significant investment. Consider these cost-effective strategies to improve efficiency:

- Implement automation where possible to reduce manual labor costs

- Simplify and standardize processes to reduce errors and delays

- Adopt lean principles to minimize waste and optimize workflows

- Invest in training and development programs to boost employee performance and retention

Research from McKinsey & Company highlights that adopting lean principles can improve warehouse efficiency by up to 20%.

Optimizing Warehouse Layout

The physical layout of your warehouse can significantly impact operational efficiency and employee productivity. Consider the following layout design tips:

- Optimize vertical space to maximize storage capacity

- Minimize travel time by creating logical pathways for material handling equipment

- Ensure adequate lighting and ventilation for employee safety and comfort

- Design ergonomic workstations to enhance efficiency

Studies from the Warehouse & Logistics News suggest that efficient layout designs can increase warehouse productivity by up to 30%.

Avoiding Common Selection Mistakes

Selecting the wrong warehouse can lead to operational inefficiencies and increased costs. Avoid these common mistakes:

- Choosing the Cheapest Option: Opting for the lowest cost warehouse might result in higher transportation and operational costs in the long run.

- Overlooking Location Importance: Ignoring the significance of location can lead to increased transportation costs and longer delivery times.

- Neglecting Facility Inspection: Failing to thoroughly inspect the warehouse condition can result in unexpected maintenance issues.

- Ignoring Future Growth: Not considering future expansion can limit your ability to scale operations.

- Disregarding Safety and Security: Overlooking safety and security measures can expose your inventory to risks.

By carefully evaluating these factors, you can select a warehouse that aligns with your business needs and supports your growth objectives.

Conclusion

Choosing the right warehouse is a critical decision that can significantly influence your business's operational efficiency and financial performance. By considering key factors such as location, storage needs, technology, and legal requirements, you can make an informed choice that supports your business objectives. Additionally, implementing effective inventory management and safety measures will help optimize your warehouse operations, reduce costs, and enhance overall productivity. Take the time to evaluate your options carefully and seek expert advice when needed to ensure you select the warehouse that best fits your business needs.