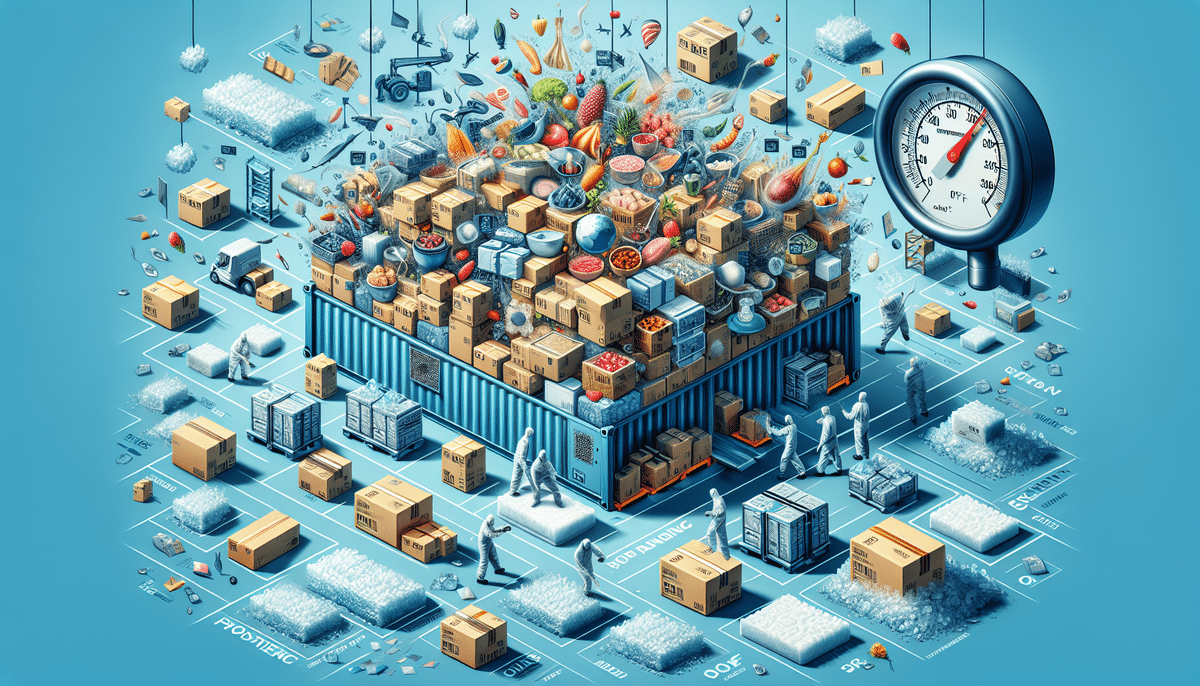

How to Ship Frozen Foods and Avoid Spoilage

Shipping frozen foods presents significant challenges due to the inherent risk of spoilage. However, with meticulous planning and appropriate packaging, you can ensure your products reach their destination in optimal condition. This article delves into the science of food spoilage, identifies the primary causes of spoilage during shipping, and offers top strategies for effectively packaging and securing frozen foods for transit.

Why Shipping Frozen Foods Can Be a Challenge

Frozen foods are highly susceptible to temperature fluctuations, requiring consistent maintenance below 0°F (-18°C) to preserve their quality and safety. Variations in temperature can lead to moisture formation and the melting and refreezing of ice crystals, resulting in freezer burn and off-flavors. Additionally, long-distance shipping exposes products to varying weather conditions and logistical hurdles.

One of the foremost challenges in shipping frozen foods is maintaining their frozen state throughout the shipping process. This necessitates coordinated efforts between the shipper, carrier, and recipient to ensure proper packaging, labeling, and transportation using temperature-controlled vehicles. According to the FDA guidelines, maintaining the cold chain is crucial to prevent spoilage and ensure food safety.

Beyond temperature control, managing inventory and order fulfillment is critical, given the limited shelf life of frozen products. Implementing accurate inventory tracking and efficient order management systems ensures timely shipments, preventing products from expiring before they reach customers.

Understanding the Science of Food Spoilage

Food spoilage is a multifaceted process involving the growth of pathogenic bacteria, oxidation, and enzymatic reactions, all of which can alter the texture, color, and flavor of food. Temperature is a pivotal factor; warmer conditions accelerate bacterial proliferation and chemical reactions that lead to spoilage.

Moisture is another critical element in spoilage. Excess moisture fosters an environment conducive to bacterial growth and can trigger chemical reactions detrimental to food quality. Consequently, storing food in a dry environment and minimizing moisture exposure are essential practices.

The type of food and its packaging significantly influence its susceptibility to spoilage. High-protein foods, such as meats and dairy products, are more prone to spoilage compared to carbohydrate-rich foods like bread and pasta. Additionally, non-airtight packaging can permit bacterial ingress, hastening spoilage. Refer to the USDA Food Safety guidelines for comprehensive insights.

The Most Common Causes of Food Spoilage During Shipping

Temperature fluctuations and moisture exposure are primary culprits in food spoilage during shipping. For instance, if frozen food packages experience thawing and refreezing, ice crystals can form, compromising the food's texture and flavor. Moreover, non-water-tight packaging allows moisture intrusion, leading to freezer burn.

Light exposure is another frequent cause of spoilage. Sensitive foods like dairy products and meats deteriorate faster when exposed to light for prolonged periods. To mitigate this, many products are packaged in opaque containers or wrapped in foil to shield them from light during transit.

Choosing the Right Packaging for Frozen Foods

Effective packaging for frozen foods must be crafted from materials that endure freezing temperatures and prevent moisture ingress. Durability is paramount to withstand rough handling during shipping. Commonly used materials include insulated boxes, foam containers, and vacuum-sealed bags. Selecting packaging appropriate for the food's size and weight is crucial for maintaining integrity.

Environmental considerations are increasingly significant in packaging choices. Eco-friendly options, such as biodegradable or compostable materials, are gaining popularity for their ability to reduce waste and pollution while appealing to environmentally conscious consumers. Balancing functionality with environmental impact is essential when selecting packaging for frozen foods.

Top Tips for Packing and Securing Frozen Foods for Shipping

Implementing the following strategies can enhance the likelihood that frozen foods arrive in excellent condition:

- Ensure Complete Freezing: Confirm that products are fully frozen before packing to maintain consistency during transit.

- Wrap Tightly: Use plastic wrap or aluminum foil to create a moisture-resistant barrier around the product.

- Secondary Protection: Place the wrapped product in a freezer bag or container to add an extra layer of protection.

- Appropriate Packaging Material: Utilize insulated foam or similar materials to shield the product from external temperature fluctuations.

- Use Sufficient Dry Ice: Incorporate adequate dry ice to sustain the required temperature throughout the shipping duration.

- Secure Packaging: Ensure that all packaging is tightly sealed to prevent movement and potential damage during transport.

Additionally, clearly labeling packages as containing frozen food and providing handling instructions can facilitate appropriate treatment during shipping and handling upon arrival. Opting for expedited shipping methods reduces the risk of thawing, further preserving product quality.

The Benefits of Using Dry Ice for Shipping Frozen Foods

Dry ice is an effective means of maintaining the optimal temperature for frozen foods during shipping. Unlike regular ice, dry ice sublimes directly from a solid to a gas without leaving residual moisture, preventing freezer burn and moisture-related spoilage. With a temperature of -109.3°F (-78.5°C), dry ice is ideal for keeping foods frozen. However, it is imperative to handle dry ice with appropriate safety measures, including using insulated gloves and ensuring proper ventilation.

Beyond its cooling efficacy, dry ice offers environmental benefits over traditional ice packs. As a byproduct of industrial processes, utilizing dry ice can contribute to reducing carbon footprints. Nonetheless, proper disposal is essential, as improper handling can pose safety hazards. Refer to the EPA guidelines for safe disposal practices.

How to Properly Label Your Frozen Food Packages for Shipping

Accurate labeling is critical for the correct handling and shipping of frozen foods. Labels should include the product name, packaging date, and any specific handling instructions. Clearly indicating the presence of dry ice and stressing the need for careful handling ensures that carriers manage the package appropriately during transit.

Including contact information for both the sender and recipient, such as phone numbers and email addresses, facilitates communication in case of shipping issues or delays. Additionally, specifying the storage temperature requirements on the label helps maintain the product’s frozen state until it reaches its destination.

Best Practices for Choosing a Shipping Carrier for Frozen Goods

Selecting the right shipping carrier is paramount for the safe transport of frozen goods. Evaluate carriers based on their experience with temperature-controlled shipping, availability of refrigerated vehicles, and comprehensive tracking and monitoring services. Ensuring that the carrier can deliver within the required timeframe minimizes the risk of thawing.

Customer service quality is another vital consideration. Partners that offer responsive and supportive customer service can address any issues promptly, ensuring a smoother shipping process. Look for carriers with dedicated support teams and 24/7 assistance capabilities.

Cost efficiency should also factor into your decision. While prioritizing safety and reliability, seek carriers that offer competitive rates and opportunities for negotiating based on shipping volume. Balancing cost with the necessity of maintaining product quality is essential for optimal shipping operations.

What to Do If Your Frozen Goods Arrive Damaged or Spoiled

In the event that frozen goods arrive in a compromised state, prompt and organized action is necessary. Begin by documenting the damage with clear photographs and detailed notes. Subsequently, contact the shipping carrier to file a formal claim for damages. Reviewing insurance policies and contracts is crucial to ensure coverage for losses incurred during shipping.

How to Maintain the Quality and Freshness of Your Frozen Foods During Transit

Maintaining consistent temperatures below 0°F (-18°C) is essential for preserving the quality and freshness of frozen foods during transit. Utilizing an adequate amount of dry ice and ensuring secure, water-tight packaging are fundamental practices. Partnering with carriers that offer temperature-controlled transportation further reduces the risk of temperature fluctuations that can lead to spoilage.

Understanding the Legal Requirements for Shipping Frozen Foods

Compliance with legal regulations is imperative when shipping frozen foods. This includes adhering to standards related to food safety, packaging, labeling, and transportation. Regulations may vary based on the origin and destination regions, necessitating thorough research and consultation with legal experts to ensure all requirements are met. The FDA regulations provide comprehensive guidelines for shipping perishable food items.

Cost Considerations When Shipping Frozen Foods

Shipping frozen foods typically incurs higher costs compared to non-perishable items due to the need for specialized packaging and temperature-controlled transportation. However, optimizing packaging efficiency and shipment sizes can mitigate some of these expenses. Selecting carriers that offer competitive rates without compromising service quality is essential for managing shipping costs effectively.

Balancing shipping costs with the value and perishability of the product ensures that expenses are justified by the necessity of maintaining food quality and safety.

Innovative Packaging Solutions for Shipping Frozen Goods in Bulk

Emerging packaging technologies are enhancing the efficiency and cost-effectiveness of shipping frozen goods in bulk. Eco-friendly packaging made from sustainable materials offers durability and effective temperature maintenance while reducing environmental impact. Additionally, smart packaging solutions equipped with temperature and condition sensors provide real-time monitoring, allowing shippers to address any issues proactively. These advancements contribute to more reliable and sustainable frozen food logistics.

The Future of Frozen Food Logistics: Emerging Trends and Technologies

The frozen food logistics industry is poised for transformation through advancements in automation, robotics, and the Internet of Things (IoT). These technologies streamline shipping processes, reduce operational costs, and enhance the quality and safety of frozen products. Automation and robotics can optimize packaging and handling, while IoT devices enable precise temperature monitoring and real-time tracking. Embracing these innovations is crucial for businesses aiming to stay competitive and meet evolving consumer demands.

Conclusion

Shipping frozen foods successfully demands detailed planning, robust packaging solutions, and unwavering attention to detail. By understanding the mechanisms of food spoilage, selecting appropriate packaging and reliable carriers, and adhering to best practices for shipping and handling, you can ensure that your frozen products retain their quality and safety upon arrival. Staying informed about emerging trends and technologies will further enhance your frozen food logistics, positioning your business for sustained success.