Integrate FedEx Ship Manager with Dymo Label Printers for an Optimized Shipping Workflow

Enhancing your shipping workflow is essential for operational efficiency and customer satisfaction. Integrating FedEx Ship Manager with Dymo Label Printers is a strategic move that not only saves time and money but also ensures your shipping labels are professional and of high quality. This comprehensive guide provides a step-by-step setup process, explores the benefits, offers troubleshooting tips, and shares best practices to help you streamline your shipping operations effectively.

The Benefits of Using FedEx Ship Manager with Dymo Label Printers

Cost and Time Efficiency

Integrating FedEx Ship Manager with Dymo Label Printers allows businesses to purchase labels in bulk, reducing the cost per label. Printing labels on-demand eliminates the need for frequent reordering, saving valuable time and minimizing downtime.

Professional and Customizable Labels

With Dymo Label Printers, you can customize labels to include your company's branding, such as logos and color schemes, ensuring a professional appearance on every package. Customized labels enhance brand recognition and provide a consistent look across all shipments.

Increased Accuracy and Reduced Errors

Automated label printing reduces the risk of human errors, such as incorrect addresses or missing information. This leads to fewer lost or misrouted packages, enhancing customer satisfaction and reducing the costs associated with shipping errors.

Streamlined Shipment Tracking and Management

The integration offers real-time tracking and management of shipments. You can monitor package statuses, receive delivery notifications, and maintain better control over your inventory, ensuring timely deliveries and efficient inventory management.

Setting Up FedEx Ship Manager with Dymo Label Printers

Step-by-Step Installation Guide

- Connect Your Dymo Label Printer: Ensure your Dymo Label Printer is properly connected to your computer via USB or network connection. Install the latest drivers from the Dymo Support page.

- Download FedEx Ship Manager: Visit the FedEx Ship Manager download page and download the appropriate version for your operating system.

- Install the Software: Run the downloaded installer and follow the on-screen instructions to install FedEx Ship Manager on your computer.

- Configure Label Printer Settings: Open FedEx Ship Manager, navigate to ‘Settings,’ and select ‘Label Printer Setup.’ Choose ‘Thermal Printer’ and select your Dymo Label Printer from the list of available printers.

- Select Label Size: Choose the label size that matches your Dymo Label Printer. Common sizes include 4x6 inches for shipping labels.

- Test the Setup: Click on ‘Test Print’ to ensure that your printer is correctly configured and that labels are printing as expected.

- Start Shipping: With the setup complete, you can now begin creating and printing shipping labels directly from FedEx Ship Manager.

For assistance during the setup process, refer to the FedEx Customer Support or visit the Dymo Support page.

Troubleshooting Common Issues

Printer Connectivity Problems

- Ensure that the Dymo Label Printer is securely connected to your computer or network.

- Verify that the correct drivers are installed and up to date.

- Restart both the printer and the FedEx Ship Manager software to reset the connection.

Label Printing Errors

- Check that the label size selected in FedEx Ship Manager matches the labels loaded in the Dymo Label Printer.

- Clean the print head of the label printer to prevent smudging or incomplete prints.

- Replace any depleted or damaged label cartridges to ensure optimal print quality.

Software Compatibility Issues

- Ensure that both FedEx Ship Manager and Dymo Label Printer firmware are updated to the latest versions.

- Verify that your operating system is compatible with the versions of the software you are using.

- Consult the FedEx Support and Dymo Support for specific compatibility solutions.

If problems persist, contacting customer support for FedEx or Dymo can provide additional assistance and troubleshooting steps.

Advanced Tips and Best Practices

Optimizing Label Designs

Utilize high-resolution images and clear fonts in your label designs to ensure readability. Incorporate QR codes or barcodes for efficient scanning and tracking. Tools like Adobe Illustrator can help create professional label designs.

Automating Shipping Processes

Leverage the automation features in FedEx Ship Manager to schedule shipments, automate label printing for recurring orders, and integrate with e-commerce platforms. This reduces manual input and speeds up the shipping process.

Maintaining Printer Health

Regularly clean your Dymo Label Printer to prevent dust buildup and print head clogs. Store label cartridges in a cool, dry place to extend their lifespan. Schedule periodic maintenance checks to ensure sustained performance.

Leveraging Batch Shipping and Address Management

Use batch shipping features to process multiple shipments simultaneously, saving time on large orders. Maintain an organized address book to quickly select frequently used shipping destinations, reducing the time spent on manual entry.

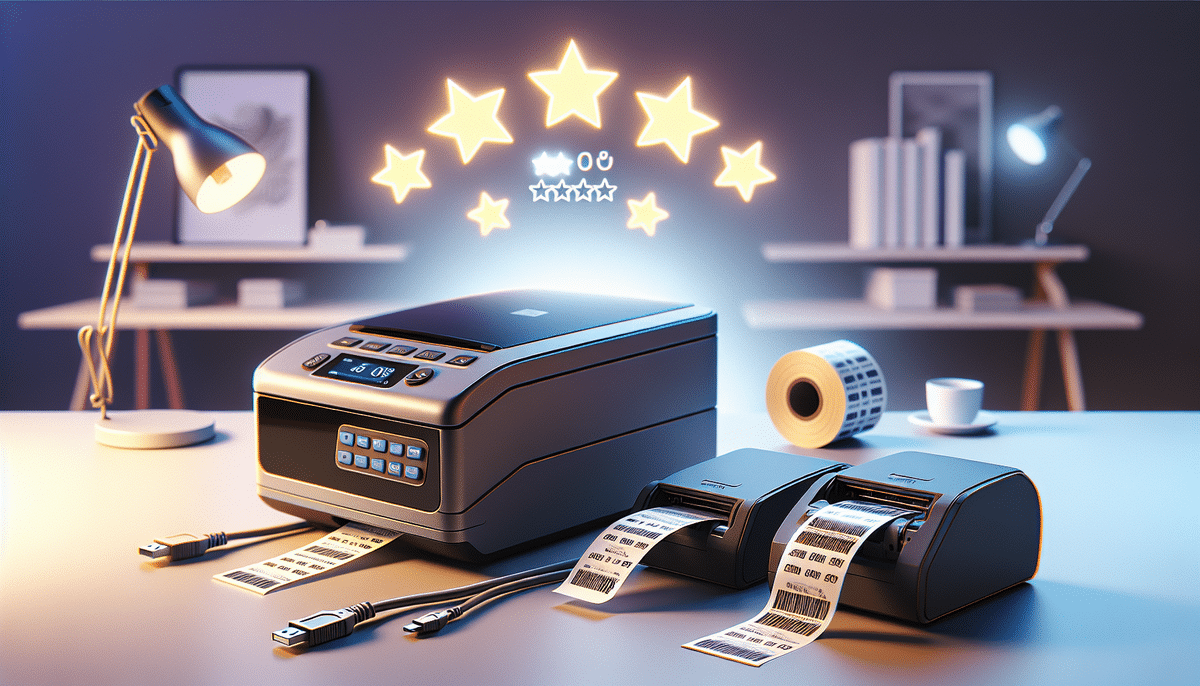

Comparing Dymo Label Printer Models Compatible with FedEx Ship Manager

Dymo LabelWriter 4XL

The Dymo LabelWriter 4XL is ideal for high-volume shipping needs, offering fast printing speeds and the ability to handle larger label sizes (4x6 inches). It is highly compatible with FedEx Ship Manager, making it suitable for businesses that require efficient and reliable label printing.

Dymo LabelWriter 450

The Dymo LabelWriter 450 is well-suited for small to medium-sized businesses. It supports a variety of label sizes and types, including address labels and barcode labels, providing flexibility for different shipping requirements.

Dymo LabelWriter Wireless

The Dymo LabelWriter Wireless offers the convenience of wireless connectivity, allowing multiple devices to connect to the printer without the need for physical cables. This model is perfect for businesses that require mobility and ease of access across different workstations.

Each of these models integrates seamlessly with FedEx Ship Manager, offering features tailored to various business needs and shipping volumes.

Maintaining Your Dymo Label Printer for Optimal Performance

Regular Cleaning

Clean the exterior of the printer with a soft, dry cloth to remove dust and debris. Periodically clean the print head using isopropyl alcohol and a lint-free cloth to prevent ink buildup and ensure clear prints.

Proper Storage of Labels

Store label cartridges in a cool, dry place away from direct sunlight to maintain their quality. Proper storage prevents label deformation and prolongs the lifespan of the labels.

Software Updates

Keep both FedEx Ship Manager and Dymo Label Printer software updated to the latest versions. Updates often include important bug fixes, security patches, and new features that enhance functionality and compatibility.

Handling and Replacing Label Cartridges

Handle label cartridges with care to avoid bending or tearing. Replace cartridges promptly when labels begin to show signs of wear or printing quality decreases. Refer to the Dymo Support for instructions on replacing cartridges.

Leveraging Automation and Advanced Techniques

Automation Features in FedEx Ship Manager

FedEx Ship Manager offers various automation features such as automated shipment scheduling, batch label printing, and integration with e-commerce platforms. Utilizing these features can significantly reduce manual workload and streamline the shipping process.

Using Barcode and QR Code Technologies

Incorporate barcodes and QR codes into your shipping labels to enhance tracking and inventory management. Dymo Label Printers are capable of producing high-quality barcodes and QR codes that are easily scanned, improving accuracy and efficiency in package handling.

Integrating Additional Shipping Services

If your business uses multiple shipping carriers, ensure that your Dymo Label Printer and FedEx Ship Manager setup can accommodate these services. Customize label templates to include specific carrier information, allowing seamless integration and flexibility in your shipping options.

Implementing Barcode Scanners

Integrate barcode scanners into your workflow to automate package tracking and reduce the risk of human error. Scanners can quickly read barcodes on labels, updating shipment statuses in real-time and improving overall operational efficiency.

Conclusion

Integrating FedEx Ship Manager with Dymo Label Printers offers substantial benefits, including cost and time savings, enhanced label quality, and a streamlined shipping process. By following the step-by-step setup guide, addressing common troubleshooting issues, and implementing advanced best practices, businesses can optimize their shipping workflows for greater efficiency and accuracy. Whether you operate a small business or a large enterprise, this integration is a valuable investment that can significantly improve your shipping operations and customer satisfaction.