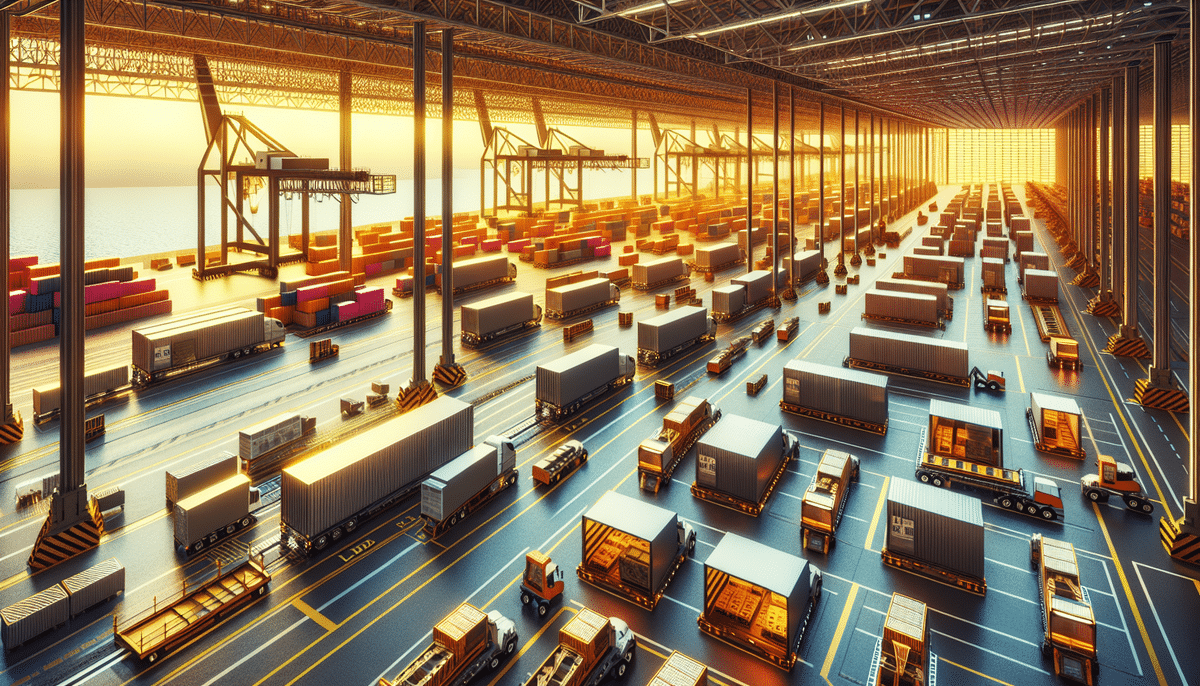

How ULDs Are Revolutionizing the Supply Chain

Unit Load Devices (ULDs) have transformed the transportation industry by providing durable containers and pallets specifically designed for the efficient movement of cargo across various transportation modes, including air, sea, and land. According to the 2023 Air Cargo Industry Report, ULDs account for over 60% of cargo shipments, highlighting their critical role in the supply chain. In this article, we delve into the significance of ULDs, explore their types, discuss their advantages, examine innovations in ULD technology, and speculate on future trends shaping their evolution.

The Importance of ULDs in the Air Cargo Industry

ULDs have been instrumental in enhancing the efficiency of the air cargo industry. By enabling airlines to load and unload cargo within minutes, ULDs significantly reduce turnaround times, allowing for more flights and higher revenue potential. A study by IATA found that the implementation of standardized ULDs can lead to a 15% increase in cargo handling efficiency.

Beyond efficiency, ULDs offer a cost-effective solution. Their reusability and rental options allow airlines to minimize capital expenditures associated with acquiring cargo containers. Additionally, ULDs enhance cargo security and integrity by providing robust protection against damage and theft during transit. With customizable sizes and shapes, they maximize cargo hold utilization, enabling airlines to transport larger volumes of goods per flight.

The Basics of ULDs: What They Are and How They Work

ULDs are available in various shapes and sizes, constructed from materials such as aluminum, steel, and advanced composites. Adhering to standardized dimensions ensures compatibility across different transportation modes. Rectangular ULDs are prevalent as they optimize space utilization within cargo holds. Each ULD is equipped with specific markings and labels indicating contents, weight limits, and handling instructions, which streamline cargo management and compliance with safety regulations.

Loading and unloading ULDs involve specialized equipment like conveyor belts and ULD loaders, which expedite the process while minimizing manual handling risks. This mechanization not only enhances operational efficiency but also reduces the likelihood of workplace injuries. ULDs accommodate a wide array of cargo, including perishable items, hazardous materials, oversized goods, and even live animals, providing versatile solutions for diverse transportation needs.

The design integrity of ULDs ensures they can withstand the extreme conditions of air travel, including temperature fluctuations, pressure changes, and high altitudes. Their stackable nature allows for optimal space usage within cargo holds, contributing to the overall efficiency of global supply chains.

The History and Evolution of ULDs in the Supply Chain

ULDs emerged in the 1950s as the air cargo industry sought more efficient and secure methods for transporting goods. Early ULDs were primarily made from steel, but advancements in materials science have led to the use of lighter and more durable materials such as aluminum and composite fibers. This evolution has not only reduced the weight of ULDs, contributing to fuel savings, but also enhanced their longevity and reliability.

Technological advancements have further revolutionized ULD operations. Automated tracking systems and RFID technology now allow for real-time monitoring of ULD locations, improving logistics management and reducing the incidence of lost or misplaced containers. The integration of ULDs into multi-modal transportation networks has expanded their utility beyond air freight, facilitating seamless transitions across sea and land transport.

Today, ULDs are indispensable in the global supply chain, offering standardized solutions that enhance cargo handling efficiency, reduce costs, and ensure the safe transportation of goods across continents.

Types of ULDs: Containers, Pallets, and Nets

ULDs are categorized into three primary types:

- Containers: Enclosed boxes designed to fit within an aircraft's cargo hold, providing secure storage for a variety of goods.

- Pallets: Flat structures placed on top of containers, capable of supporting luggage, cartons, and heavy cargo items.

- Nets: Flexible restraints used to secure cargo within ULDs, preventing movement and potential damage during transit.

Each type serves a specific function, contributing to the overall efficiency and versatility of cargo transportation. The standardized design of ULDs ensures compatibility with different aircraft models and facilitates easy tracking and management through centralized systems.

Advantages of Using ULDs in the Transportation of Goods

Utilizing ULDs in cargo transportation offers numerous benefits:

- Efficiency: Streamlined loading and unloading processes reduce turnaround times and increase flight frequency.

- Cost-Effectiveness: Reusable ULDs lower the need for additional packaging materials and minimize capital expenditures for airlines.

- Space Optimization: Stackable and customizable ULDs maximize cargo hold utilization, allowing more goods to be transported per flight.

- Enhanced Security: Robust construction protects cargo from damage and theft, ensuring the integrity of goods during transit.

- Compliance: Designed to meet stringent safety standards, ULDs ensure adherence to regulatory requirements across different transportation modes.

Moreover, the eco-friendly aspect of ULDs cannot be overlooked. By reducing the reliance on single-use packaging and improving transportation efficiency, ULDs contribute to lower carbon emissions and a more sustainable supply chain.

How ULDs Improve Efficiency in the Supply Chain

ULDs play a pivotal role in enhancing the overall efficiency of supply chains. Their standardized dimensions facilitate seamless integration across various transportation modes, enabling quick transfers between air, sea, and land logistics. This interoperability reduces delays and streamlines the movement of goods, ensuring timely deliveries.

Furthermore, the use of ULDs minimizes manual handling, thereby reducing the potential for human error and increasing cargo handling speed. Automated tracking and inventory management systems associated with ULDs provide real-time visibility into cargo movements, allowing for better planning and resource allocation.

By enabling the transportation of larger cargo volumes in single shipments, ULDs decrease the number of trips required, leading to significant savings in transportation costs and resource utilization.

Reducing Costs with ULDs: A Case Study

A case study conducted by ShipScience revealed that airlines implementing standardized ULDs reduced their operational costs by up to 50%. The study highlighted several factors contributing to these savings:

- Decreased Handling Time: Automated loading and unloading processes accelerated cargo processing.

- Minimized Cargo Damage: Enhanced cargo protection reduced loss and damage-related expenses.

- Optimized Space Utilization: Increased cargo capacity lowered the number of flights needed.

- Reduced Packaging Costs: Reusable ULDs eliminated the need for excessive packaging materials.

Additionally, the study noted improvements in cargo safety and worker productivity, underscoring the multifaceted benefits of adopting ULDs in cargo transportation.

Innovations in ULD Technology: IoT and Beyond

The future of ULDs is being shaped by several technological advancements:

- Internet of Things (IoT): Integration of IoT sensors allows for real-time tracking and monitoring of ULDs, providing data on location, temperature, and handling conditions. This enhances supply chain visibility and allows for proactive management of potential issues.

- 3D Printing: Customization of ULDs through 3D printing enables the production of containers tailored to specific cargo needs, improving space utilization and reducing waste.

- Lightweight Materials: Adoption of materials like carbon fiber and advanced composites reduces the weight of ULDs, leading to significant fuel savings and lower carbon emissions.

- Smart ULDs: Development of ULDs with built-in electronic devices for automated inventory management and enhanced security measures.

These innovations are poised to further enhance the efficiency, sustainability, and functionality of ULDs, driving the next generation of supply chain solutions.

ULD Maintenance Best Practices

Maintaining ULDs in optimal condition is crucial for their reliability and longevity. Best practices for ULD maintenance include:

- Regular Inspections: Periodic checks for structural integrity, wear and tear, and compliance with safety standards.

- Cleaning: Thorough cleaning to prevent contamination and corrosion, ensuring that ULDs remain suitable for transporting various types of cargo.

- Repairs: Timely repairs of any damages to maintain the functionality and safety of ULDs.

- Proper Storage: Storing ULDs in dry, cool environments to protect them from moisture and extreme temperatures.

- Handling Procedures: Training personnel on correct handling techniques to prevent accidental damage during loading and unloading.

Adhering to these maintenance practices ensures that ULDs continue to perform reliably, supporting the smooth operation of supply chains and safeguarding the integrity of transported goods.

Regulatory Compliance for ULD Use and Transportation

Compliance with regulations governing ULD use and transportation is essential for safety and operational integrity. Key regulatory bodies include the Federal Aviation Administration (FAA) in the United States and the International Air Transport Association (IATA) globally. These organizations establish standards for ULD design, testing, and operational procedures to ensure consistent safety and performance across the industry.

Failure to comply with ULD regulations can lead to severe penalties, including fines and operational restrictions. Moreover, non-compliance increases the risk of cargo damage and safety hazards, which can have far-reaching consequences for businesses and stakeholders involved in the supply chain. Staying informed about the latest regulatory updates and implementing best practices for compliance are critical for maintaining operational excellence and ensuring the safe transport of goods.

The Future of ULDs: Trends and Predictions

The trajectory of ULD development points towards increased integration with smart technologies and sustainability initiatives. Emerging trends include:

- Advanced Tracking Systems: Enhanced real-time monitoring capabilities through IoT and blockchain technologies, improving transparency and traceability within the supply chain.

- Sustainable Materials: Greater use of recyclable and eco-friendly materials to reduce the environmental impact of ULD production and disposal.

- Modular Designs: Flexible ULD designs that can be easily reconfigured to accommodate different types of cargo, enhancing versatility.

- Automated Handling: Increased automation in ULD handling processes, leveraging robotics and AI to further boost efficiency and reduce human error.

As the transportation industry evolves, ULDs will continue to adapt, incorporating innovative technologies and sustainable practices to meet the growing demands of global supply chains. These advancements promise to make ULDs even more efficient, cost-effective, and environmentally friendly, solidifying their role as a cornerstone of modern logistics.

In conclusion, ULDs have fundamentally transformed the transportation landscape by enhancing efficiency, reducing costs, and ensuring the safe transport of a wide array of goods. With ongoing innovations and a focus on sustainability, the future of ULDs is poised to drive further advancements in the global supply chain.