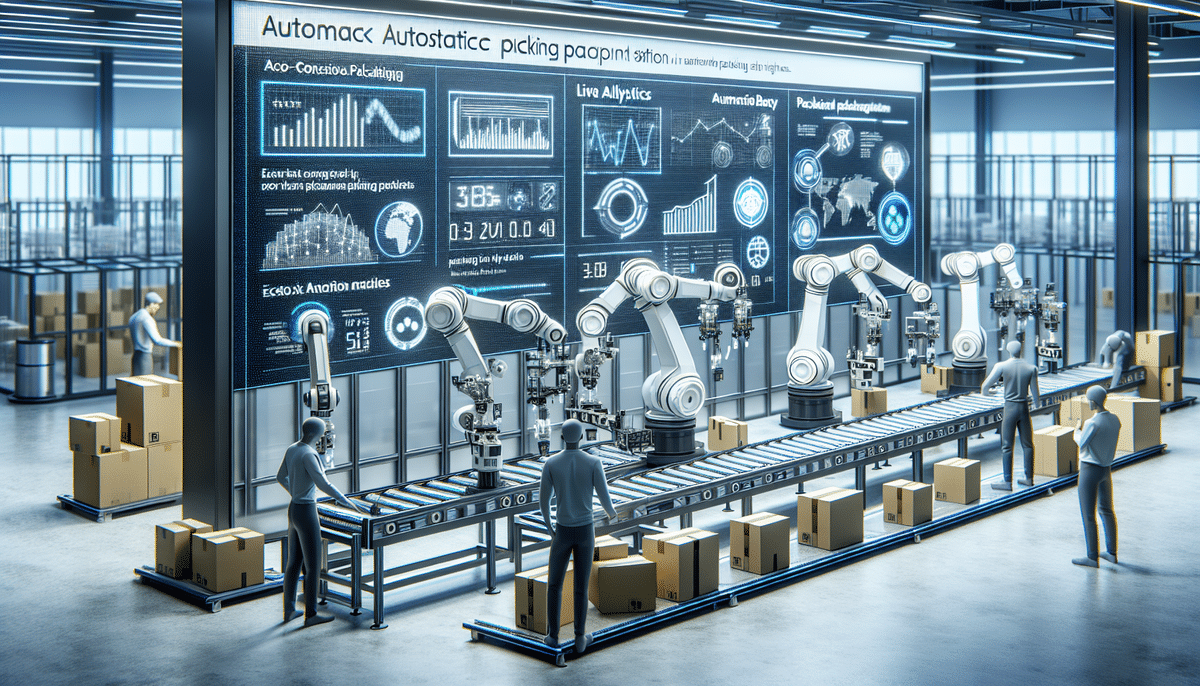

Introduction to Adaptive Packing Stations

The packaging industry is undergoing a significant transformation, with adaptive packing stations emerging as a key innovation. These advanced systems mark a shift from traditional manual packing methods to automated, highly efficient operations. This article explores the development, advantages, challenges, and future prospects of adaptive packing stations, emphasizing their transformative impact across various sectors.

Benefits of Adaptive Packing Stations

Enhanced Productivity and Efficiency

Adaptive packing stations streamline the packaging process by automating tasks that were previously manual and time-consuming. This automation leads to increased productivity, allowing businesses to handle larger order volumes with greater efficiency.

- Increased Output: Automation accelerates the packaging process, enabling higher production rates.

- Cost Savings: Reduces labor costs and minimizes material waste, contributing to significant cost reductions.

- Precision and Consistency: Ensures uniform packaging quality, decreasing errors and the incidence of damaged goods.

According to a Forbes report, companies implementing adaptive packing stations have experienced a productivity boost of up to 30% within the first year.

Sustainability and Waste Reduction

Adaptive packing stations contribute to environmental sustainability by optimizing the use of packaging materials and enhancing waste management processes.

- Material Efficiency: Precise measurement and dispensing of materials reduce excess usage.

- Recycling Integration: Facilitates the sorting and recycling of materials, promoting sustainable practices.

- Energy Efficiency: Some systems are designed to incorporate renewable energy sources, further lowering their carbon footprint.

Improved Customer Satisfaction

By ensuring faster turnaround times and accurate order fulfillment, adaptive packing stations enhance the overall customer experience.

- Consistent Quality: Guarantees that products arrive in excellent condition, fostering customer trust.

- Faster Deliveries: Speeds up processing and shipping, meeting customer expectations for quick delivery.

- Eco-Friendly Packaging: Appeals to environmentally conscious consumers, enhancing brand reputation.

Technology Behind Adaptive Packing Stations

Core Components

The functionality of adaptive packing stations is powered by a combination of advanced technologies:

- Sensors: Monitor packaging parameters in real-time, ensuring precise operations.

- Robotics: Enable accurate handling and placement of items, adapting to various sizes and shapes.

- Custom Software: Analyzes data to optimize packaging processes, enhancing efficiency and reducing costs.

Integration and Automation

Adaptive packing stations seamlessly integrate with existing inventory management and shipping systems, creating a unified workflow from order processing to delivery. This integration ensures timely fulfillment and maintains high-quality standards.

Implementation Challenges and Solutions

Common Challenges

Implementing adaptive packing stations can present several obstacles, including:

- High Initial Investment: The upfront costs for automated systems can be significant.

- Skilled Workforce Requirement: Operating and maintaining advanced systems requires specialized training.

- System Complexity: Integrating new technologies with existing processes can be complex and time-consuming.

Strategies to Overcome Challenges

Businesses can address these challenges by:

- Investing in Training: Providing comprehensive training programs to equip employees with the necessary skills.

- Conducting ROI Analyses: Evaluating the return on investment to justify the initial expenditure and plan for long-term benefits.

- Customizing Solutions: Collaborating with vendors to tailor systems to specific business needs, ensuring seamless integration.

Future Trends in Adaptive Packing Stations

The packaging industry is poised for further advancements, with adaptive packing stations at the forefront of innovation. Key trends include:

- Advanced AI Integration: Leveraging artificial intelligence for enhanced decision-making and process optimization.

- IoT Connectivity: Utilizing Internet of Things (IoT) technologies for real-time data sharing and monitoring.

- Sustainable Innovations: Developing eco-friendly materials and energy-efficient systems to promote environmental sustainability.

- Increased Customization: Offering greater flexibility to accommodate diverse packaging needs and unique product specifications.

As businesses strive to stay competitive, the adoption of adaptive packing stations is expected to accelerate, driven by the need for greater efficiency, sustainability, and superior customer experiences.

Conclusion

Adaptive packing stations represent a significant advancement in the packaging industry, offering automated, efficient, and precise solutions for order processing and packaging. Despite the challenges associated with implementation, the benefits—including faster turnaround times, reduced labor costs, increased efficiency, and enhanced customer satisfaction—make adaptive packing stations a valuable investment for businesses aiming to thrive in a dynamic market.