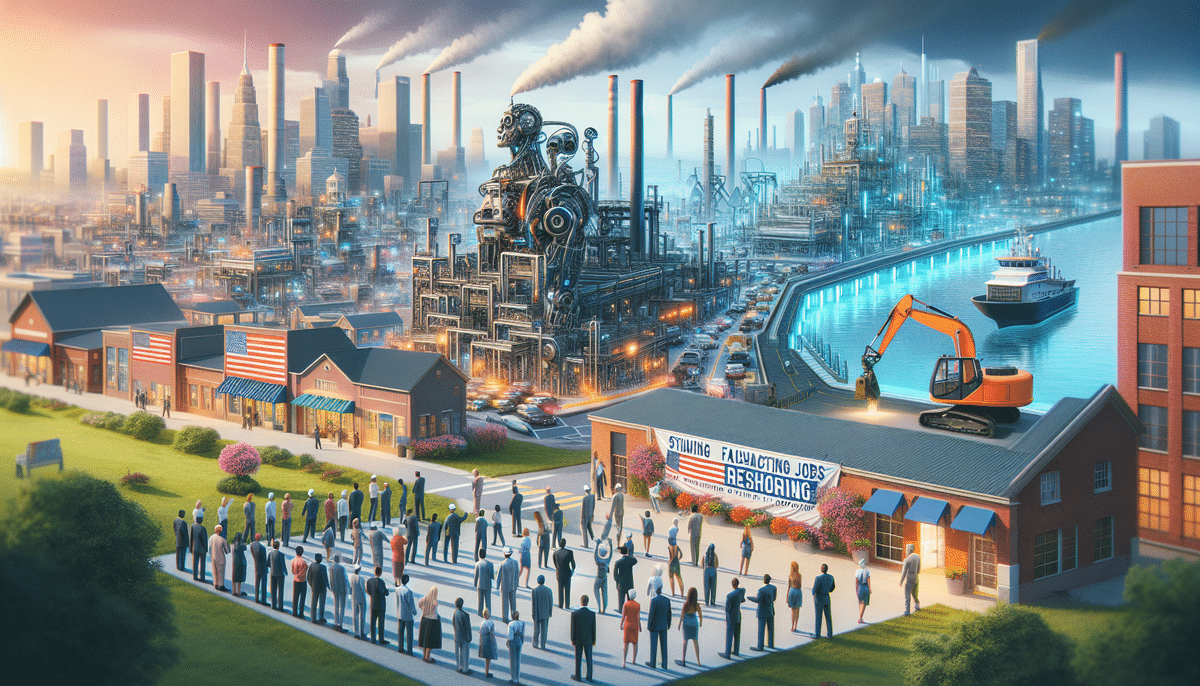

Is Reshoring Useful or Just Supply Chain Hype?

Reshoring continues to be a significant topic in the supply chain industry, generating discussions about its true value. This comprehensive analysis delves into the concept of reshoring, evaluating its effects on businesses, local economies, and government policies. Additionally, we compare reshoring with offshoring, examine both successful and unsuccessful case studies, and explore future trends and challenges.

Defining Reshoring: What Does it Mean for Supply Chain?

Reshoring refers to the practice of relocating manufacturing and other business operations back to the company's home country from overseas. This trend has gained momentum due to factors such as escalating labor costs, quality control issues, and heightened concerns about supply chain resilience. The primary objectives of reshoring include reducing dependence on foreign suppliers, fostering local job creation, and stimulating the domestic economy.

One of the key advantages of reshoring is the enhanced control over the supply chain. Offshore manufacturing often complicates the assurance of quality standards and ethical production practices. By bringing manufacturing back home, companies can better oversee their operations and ensure products meet their precise specifications.

However, reshoring presents challenges, including the high costs associated with relocating operations and potential shortages of skilled labor in certain industries. Additionally, existing relationships with overseas suppliers may be difficult to dissolve. Despite these obstacles, many companies opt for reshoring to gain greater supply chain control and support the local economy.

Reasons Behind the Growing Trend of Reshoring

Several factors are driving the increasing number of companies considering reshoring:

- Rising Labor Costs: Countries like China and India, once favored for their low labor costs, are experiencing wage increases, making reshoring more financially viable.

- Quality Control and Intellectual Property: Managing quality and protecting intellectual property rights has become more challenging overseas, prompting companies to bring operations back home.

- Supply Chain Risks: Natural disasters and global events like the COVID-19 pandemic have exposed vulnerabilities in global supply chains, encouraging companies to seek greater resilience through reshoring.

- Consumer Demand for Locally Sourced Products: Increasing consumer awareness about environmental impacts has boosted demand for products made closer to home, allowing companies to reduce their carbon footprint.

- Job Creation: Reshoring can lead to the creation of local jobs, positively impacting the economy and reducing unemployment rates.

The Pros and Cons of Reshoring for Businesses

Reshoring offers several benefits and drawbacks for businesses:

Advantages

- Cost Reduction: Potential long-term savings through reduced transportation costs and tariffs.

- Enhanced Quality Control: Improved oversight ensures products meet quality standards.

- Economic Support: Boosts the local economy by creating jobs and fostering business growth.

- Strategic Flexibility: Allows companies to respond more swiftly to market changes.

Disadvantages

- Higher Labor Costs: Domestic labor costs can be significantly higher than those offshore.

- Skill Shortages: Difficulty in finding skilled workers in certain industries.

- Initial Investment: High costs associated with relocating operations.

- Market Access: Potential loss of access to international markets due to trade barriers and tariffs.

Additionally, reshoring may not be feasible for businesses reliant on specialized overseas suppliers or raw materials, potentially leading to increased costs or compromised quality.

Analyzing the Impact of Reshoring on Local Economies

Reshoring can significantly influence local economies by:

- Job Creation: Returning jobs can reduce unemployment and increase local spending.

- Increased Productivity: Enhanced efficiency and innovation from a skilled local workforce.

- Support for Small Businesses: Stimulates growth of local suppliers and service providers.

- Balanced Economic Growth: Helps reduce trade deficits by increasing domestic production.

However, there is a risk that reshoring could exacerbate income inequality if it disproportionately benefits skilled labor over unskilled workers.

The Role of Government Policies in Encouraging Reshoring

Government policies are pivotal in promoting reshoring through various incentives such as:

- Tax Incentives: Reductions or credits to lower the cost of domestic operations.

- Investment Funds and Subsidies: Financial support to offset relocation expenses.

- Worker Training Programs: Collaborations with educational institutions to develop a skilled workforce.

- Infrastructure Development: Enhancing logistical networks to support domestic manufacturing.

Additionally, governments can facilitate the reshoring process by simplifying legal and regulatory requirements, assisting in site selection, and supporting logistics and transportation needs.

Public awareness campaigns highlighting the benefits of locally produced goods can also drive consumer demand, creating a more favorable environment for reshoring.

Case Studies: Successful and Failed Examples of Reshoring

Examining real-world examples provides insight into the reshoring process:

Successful Reshoring

- GE's Appliance Park in Kentucky: Successfully created jobs and enhanced productivity.

- Apple's Mac Pro Production: Reduced reliance on Chinese manufacturing and leveraged the skilled U.S. workforce and advanced technology.

Failed Reshoring

- Levi's Clothing Production: Struggled to transition from offshoring, highlighting the complexities of reshoring apparel manufacturing.

- Walmart's Apparel Production: Faced higher labor costs and insufficient infrastructure, making it difficult to compete with overseas suppliers.

These examples underscore the importance of considering industry-specific factors and company capabilities when pursuing reshoring.

Reshoring vs Offshoring: A Comparative Study

Understanding the differences between reshoring and offshoring is crucial for strategic decision-making:

Reshoring

- Advantages: Reduced supply chain risks, enhanced quality control, and support for the local economy.

- Disadvantages: Higher labor costs and potential market access limitations.

Offshoring

- Advantages: Cost savings through lower labor expenses and access to a large talent pool.

- Disadvantages: Increased supply chain vulnerabilities and challenges in maintaining quality standards.

The decision between reshoring and offshoring depends on a company’s strategic priorities, required skill sets, and stakeholder expectations.

The COVID-19 pandemic has further emphasized the need for supply chain resilience, prompting many companies to reevaluate their offshoring strategies and consider reshoring as a viable option.

The Future of Reshoring: Predictions and Challenges

Looking ahead, reshoring's trajectory will be influenced by:

- Trade Policies: Evolving international trade agreements and tariffs.

- Local Regulations: Domestic policies that support or hinder reshoring efforts.

- Economic Environment: Shifts in global economic conditions and consumer preferences.

Challenges that may impact the future of reshoring include:

- Skilled Workforce Availability: Ensuring access to a talented labor pool.

- Environmental Sustainability: Adopting eco-friendly practices to minimize carbon footprints.

- Market Demand Shifts: Adapting to changing consumer and market needs.

One key prediction is the increased adoption of advanced manufacturing technologies such as automation, artificial intelligence, and robotics. These technologies can lower labor costs, enhance productivity, and improve product quality, although they require significant investment and training. To support this transition, governments and industry associations are likely to offer financial incentives and training programs.

Best Practices for Companies Considering Reshoring

For companies contemplating reshoring, the following best practices are essential:

- Comprehensive Cost-Benefit Analysis: Assess the financial implications, including relocation costs and long-term savings.

- Strategic Location Selection: Choose locations that offer the necessary infrastructure and workforce.

- Collaborative Partnerships: Work with local and state governments to create an enabling environment.

- Skilled Workforce Development: Invest in training programs or partner with educational institutions to ensure access to skilled labor.

- Environmental Impact Assessment: Implement sustainable practices to minimize environmental footprints.

In conclusion, reshoring presents significant opportunities for businesses, local economies, and governments by enhancing control over production processes, creating jobs, and stimulating economic growth. However, successful reshoring requires careful evaluation of costs, risks, and strategic priorities. Companies must also consider workforce availability and environmental impacts to ensure a sustainable and profitable reshoring strategy.

For further reading and authoritative sources on reshoring, visit the ShipScience Reshoring Insights and refer to recent industry reports from reputable organizations.