Kiva Systems (Amazon Robotics) vs. 6 River Systems (Shopify)

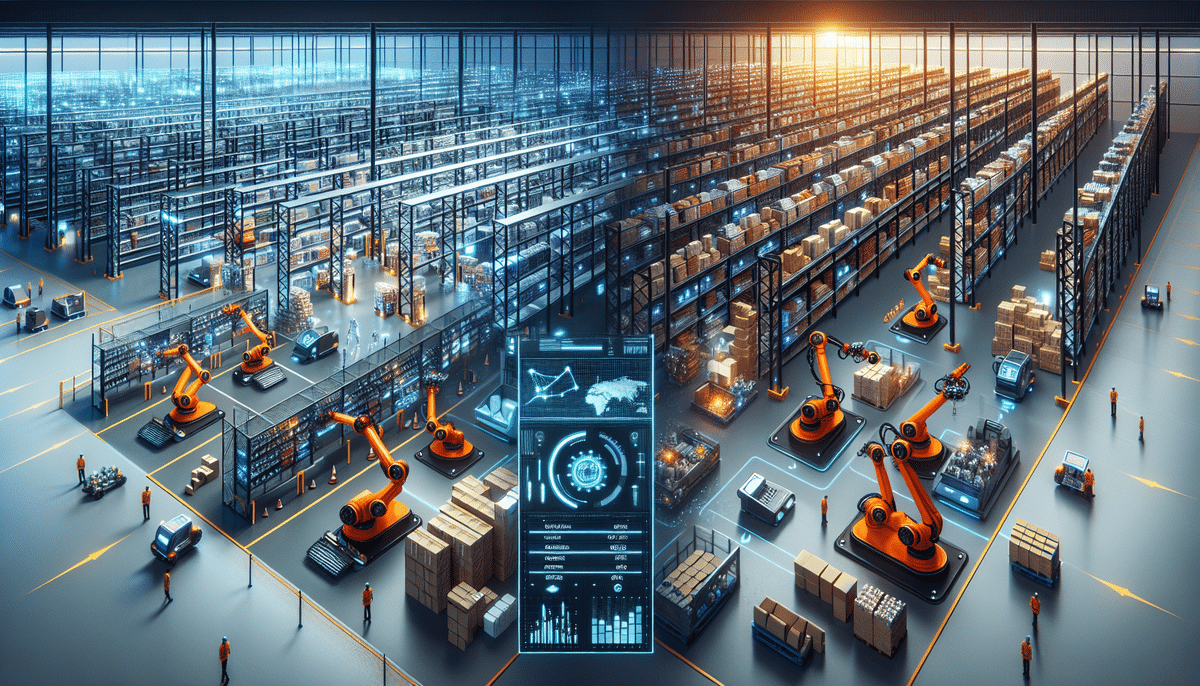

In the rapidly evolving landscape of e-commerce and warehousing, efficiency and speed in fulfillment processes are paramount. Robotic automation has become a cornerstone in achieving these objectives. Among the leading innovators in this space are Amazon Robotics (formerly Kiva Systems) and 6 River Systems, a subsidiary of Shopify. This comprehensive analysis delves into the history, technology, features, and the advantages and challenges associated with both systems.

History and Evolution of Amazon Robotics and 6 River Systems

Amazon Robotics originated as Kiva Systems, founded in 2003 with the mission to revolutionize warehouse operations through automation. By developing autonomous robots that efficiently move inventory within warehouses, Kiva significantly reduced the need for manual labor and increased operational speed. Amazon recognized the potential of this technology and acquired Kiva Systems in 2012, rebranding it as Amazon Robotics. Today, Amazon Robotics is integral to Amazon's vast distribution network, continually advancing warehouse automation technologies.

6 River Systems was established in 2015 by seasoned robotics engineers with the goal of enhancing warehouse efficiency for e-commerce businesses. The company specialized in deploying mobile robots coupled with an advanced software platform to optimize fulfillment processes. In 2019, Shopify acquired 6 River Systems, integrating its solutions to bolster Shopify's logistics and fulfillment capabilities, thereby extending its reach to a global marketplace.

Since these acquisitions, both Amazon Robotics and 6 River Systems have pushed the boundaries of warehouse automation. Amazon Robotics has introduced innovations like the Robo-Stow, a robotic arm for handling heavy items, and the Pegasus Drive, a mobile robot for transporting large inventory volumes. Meanwhile, 6 River Systems has focused on enhancing software flexibility and robot adaptability to cater to diverse warehouse environments.

Purpose and Functionality of Amazon Robotics and 6 River Systems

The core objective of both Amazon Robotics and 6 River Systems is to automate warehouse operations, thereby increasing speed, efficiency, and accuracy. These systems deploy autonomous robots to transport items between storage areas and shipping zones, streamlining the fulfillment process and minimizing human intervention in repetitive tasks. This automation not only enhances productivity but also contributes to a safer working environment, leading to significant cost reductions.

Both systems incorporate advanced analytics and reporting tools, monitoring inventory levels, order fulfillment rates, and key performance indicators (KPIs). These insights enable warehouse managers to make informed, data-driven decisions to further optimize their operations.

Continuous technological advancements ensure that Amazon Robotics and 6 River Systems remain at the forefront of warehouse automation. Amazon Robotics has rolled out faster and more efficient robots, while 6 River Systems has developed software platforms that offer greater customization and scalability, catering to a wide range of warehouse sizes and requirements.

Pros and Cons of Amazon Robotics and 6 River Systems

Pros of Amazon Robotics

- Proven Track Record: Successfully integrated into Amazon's logistics network, showcasing reliability and effectiveness.

- High Operational Speed: Capable of processing a large number of deliveries per hour, significantly boosting overall efficiency.

- User-Friendly Interface: Simplified setup and management, accessible even to users without extensive robotics expertise.

- Robust Support: Backed by Amazon's substantial resources, ensuring strong customer support and ongoing technological advancements.

Cons of Amazon Robotics

- High Implementation Costs: Requires a significant initial investment, which may be prohibitive for small and medium-sized enterprises.

- Space Requirements: Necessitates considerable adjustments to warehouse layouts to accommodate autonomous robots.

- Limited Flexibility: Optimized for large warehouses with uniform inventory, making it less suitable for specialized or highly diverse inventories.

Pros of 6 River Systems

- Lower Implementation Costs: More affordable, increasing accessibility for smaller companies.

- Ease of Use: Intuitive platform that is easy for all warehouse staff to learn and navigate.

- Versatile Interface: Supports multiple simultaneous tasks, enhancing operational flow and efficiency.

- Adaptable to Various Sizes: Suitable for a range of warehouse sizes, from startups to large enterprises.

Cons of 6 River Systems

- Slower Operational Speed: Processes fewer deliveries per hour compared to Amazon Robotics, which may impact overall efficiency.

- Limited Capabilities: May not fully meet the needs of specialized warehouses with unique inventory management requirements.

- Customer Support Limitations: Less extensive support infrastructure compared to Amazon Robotics, potentially leading to longer delays in updates and issue resolution.

Both Amazon Robotics and 6 River Systems are continuously evolving, with recent updates including Amazon Robotics' new robots capable of handling a broader range of products and 6 River Systems' improvements in robot speed and efficiency. Staying informed about these advancements is essential for businesses when selecting the most appropriate warehouse automation solution.

Comparison of Features and Capabilities

Robotic Hardware

Amazon Robotics employs mobile robots equipped with advanced sensors for navigating complex warehouse environments. These robots are capable of lifting and transporting up to 1,000 pounds, making them ideal for handling large and heavy inventory items. In contrast, 6 River Systems utilizes smaller robots designed to lift up to 150 pounds, making them more suitable for compact or specialized warehousing spaces.

Software Platform

Both systems offer user-friendly interfaces that facilitate plug-and-play setup without requiring extensive programming knowledge. Amazon Robotics focuses on ease of use with streamlined workflows, while 6 River Systems provides a more customizable software platform. 6 River's software includes advanced graphical user interfaces that offer greater flexibility and integration capabilities with existing warehouse management systems.

Flexibility

6 River Systems excels in flexibility, catering to both large and small warehouses and supporting a wide range of product types. This adaptability makes it suitable for businesses with diverse inventory management needs. On the other hand, Amazon Robotics is optimized for large-scale operations with homogeneous inventory, offering less adaptability for highly specialized or varied inventory systems.

Enhancing Warehouse Efficiency with Amazon Robotics

Amazon Robotics has revolutionized Amazon's fulfillment centers by automating processes that were previously time-consuming and labor-intensive. This automation enables faster picking and shipping of products, leading to higher customer satisfaction and retention rates. Robots handle tasks such as moving inventory, reducing the need for employees to traverse large warehouse spaces, which decreases the risk of workplace injuries and enhances overall productivity. Additionally, precise inventory management minimizes stockouts and overstocks, ensuring optimal inventory levels.

Enhancing Fulfillment for E-commerce Businesses with 6 River Systems

6 River Systems provides a user-friendly automation platform that helps e-commerce businesses optimize warehouse organization, reduce customer wait times, and lower order cancellation rates. Integrating robots into the fulfillment process offers several key benefits:

- Increased Productivity: Automation accelerates order processing and handling.

- Cost Savings: Reduced reliance on manual labor lowers operational expenses.

- Improved Workflow: Enhanced warehouse workflows create a more efficient and organized environment.

The Technology Behind Amazon Robotics and 6 River Systems

Both Amazon Robotics and 6 River Systems utilize sensor-based robotics technology for warehouse navigation, but their approaches differ:

- Amazon Robotics: Uses a network of shelf-level storage and dedicated channels within which mobile robots operate, optimizing space usage for large inventories.

- 6 River Systems: Deploys ground-moving robots that offer greater flexibility, making them suitable for smaller and more diverse warehouse environments.

Cost Analysis: Amazon Robotics vs. 6 River Systems

The implementation costs for Amazon Robotics and 6 River Systems vary significantly. Generally, Amazon Robotics demands a higher initial investment due to its advanced robotic hardware and extensive integration processes. This makes it a substantial financial commitment, potentially limiting its adoption to larger enterprises.

In contrast, 6 River Systems offers a more affordable software platform that is accessible to smaller companies. However, the lower cost may come with limitations in terms of customizability and the frequency of software updates, which could impact long-term scalability and functionality.

Customer Feedback: Effectiveness of Amazon Robotics vs. 6 River Systems

Customer reviews for both systems are largely positive. Users of Amazon Robotics commend its ability to enhance efficiency, speed, and productivity within their warehouses. The integration with Amazon's logistics network further adds to its credibility and effectiveness.

Conversely, 6 River Systems receives praise for its ease of use, customization options, and affordable pricing. However, some users have noted the necessity for manual oversight, particularly for startups or smaller businesses that may lack the resources to manage these tasks effectively.

The Future of Robotic Automation in Warehousing and E-commerce

Robotic automation in warehousing and e-commerce is set for significant advancements as technology continues to progress. Robotics companies are expanding their product offerings to cater to a broader audience and enhance their capabilities. Future developments may include more intelligent and adaptable robots, integration with advanced AI for predictive analytics, and further reductions in operational costs. These innovations will enable companies to harness greater benefits from automation technologies, ensuring sustained improvements in logistics and operational efficiencies.

Choosing the Right System for Your Business: Amazon Robotics vs. 6 River Systems

When selecting between Amazon Robotics and 6 River Systems for warehouse automation, several critical factors should be considered:

- Warehouse Size: Larger warehouses with high inventory diversity may benefit more from Amazon Robotics, while smaller or specialized warehouses might find 6 River Systems more suitable.

- Budget: Companies with higher budgets may opt for Amazon Robotics despite the higher initial costs, whereas those with limited budgets may prefer the more cost-effective 6 River Systems.

- Product Type: Businesses handling a wide variety of products might require the robust capabilities of Amazon Robotics, whereas those dealing with smaller, more uniform items could leverage the flexibility of 6 River Systems.

- Customization Needs: 6 River Systems offers more customization options, making it ideal for businesses needing tailored solutions.

If your warehouse environment features high diversity in storage needs, manages smaller items, or operates in confined spaces, 6 River Systems is an excellent choice. Its platform is scalable, customizable, and integrates seamlessly with other software solutions, providing ample flexibility.

Conversely, for larger warehouses, Amazon Robotics offers a comprehensive and well-tested solution for automating warehousing and logistics operations. Its proven reliability, accuracy, and safety features ensure significant operational improvements, making it a dependable choice for enterprises seeking to enhance their logistics processes.