Kiva Systems (Amazon Robotics) vs Dematic: A Comprehensive SEO-Optimized Comparison

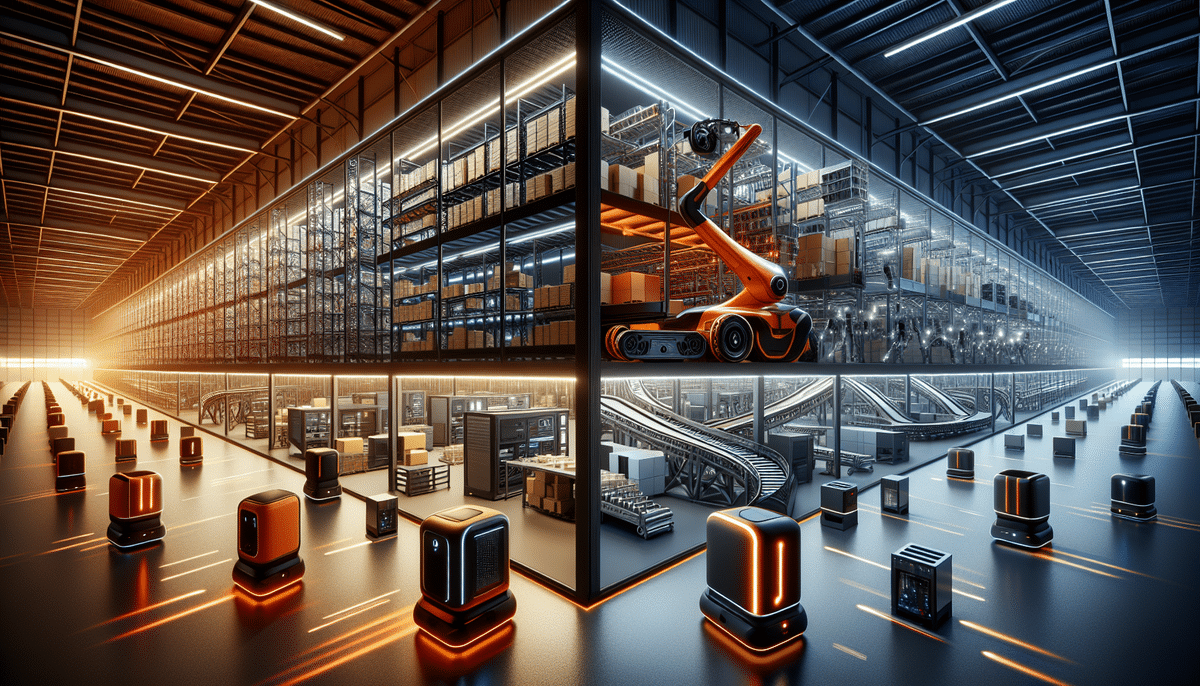

In the evolving landscape of warehouse automation, Kiva Systems (now Amazon Robotics) and Dematic stand out as leading innovators. With the exponential growth of e-commerce, the demand for streamlined and efficient warehouse operations has surged. This article offers an in-depth analysis of both Kiva Systems and Dematic, highlighting their strengths and assisting businesses in selecting the optimal automation partner.

The Evolution of Warehouse Automation: A Brief Overview

Warehouse automation has transformed significantly since its inception in the 1970s and 1980s. Early systems primarily aimed to reduce manual labor and enhance process efficiency. Over the decades, advancements in technology have shifted focus from simple material handling to intelligent systems capable of autonomous decision-making.

One of the most groundbreaking advancements is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into warehouse operations. These technologies enable systems to analyze data from sensors and cameras, facilitating real-time decision-making and operational optimization. For instance, AI-powered systems can forecast product demand, adjusting inventory levels to minimize stockouts and excess inventory [1].

Additionally, the rise of collaborative robots (cobots) has revolutionized warehouse workflows. Cobots work alongside human employees, handling tasks that require precision and adaptability, such as picking and packing, while humans focus on complex problem-solving and decision-making. This symbiotic relationship enhances overall efficiency, safety, and employee satisfaction.

What is Kiva Systems and How Does it Work?

Kiva Systems, established in 2003 and rebranded as Amazon Robotics after its acquisition by Amazon in 2012, specializes in Autonomous Mobile Robots (AMRs) for inventory management and order fulfillment. These robots navigate warehouse floors to move inventory, pick and pack orders, and replenish stock, significantly enhancing operational efficiency.

Amazon Robotics' robots are equipped with advanced sensors and algorithms, including lidar and camera systems, allowing them to navigate seamlessly and autonomously. They integrate with warehouse management systems to ensure accurate item retrieval and placement, working harmoniously with human workers to optimize the fulfillment process.

The implementation of Amazon Robotics has demonstrated substantial improvements in efficiency and productivity. According to Amazon's 2023 annual report, warehouses utilizing Amazon Robotics have seen a 30% reduction in order processing time and a 25% increase in inventory accuracy [2].

Moreover, the flexibility of Amazon Robotics' solutions allows for easy reprogramming to adapt to varying tasks, making them suitable for dynamic warehouse environments. Their seamless integration with existing warehouse systems ensures a cohesive and efficient workflow.

Dematic: A Leading Provider of Material Handling Solutions

Dematic, founded in 1819, is a global leader in automated warehouse solutions and materials handling equipment. Their extensive product portfolio includes automated storage and retrieval systems (AS/RS), shuttle systems, conveyor systems, sortation systems, and robotic equipment. Additionally, Dematic offers comprehensive warehouse control software that orchestrates these technologies to create a unified and efficient operational environment.

With over two centuries of experience, Dematic has cemented its reputation for innovation in the material handling industry. The company continuously develops cutting-edge technologies aimed at enhancing warehouse efficiency and productivity. Dematic's solutions cater to diverse industries, including retail, e-commerce, and manufacturing, and are deployed in over 25 countries worldwide.

Dematic's commitment to excellence is reflected in their global workforce of more than 10,000 employees and their dedication to providing top-tier service and support, ensuring that their systems operate at optimal performance levels [3].

The Advantages of Kiva Systems over Dematic

One of the primary advantages of Kiva Systems is its inherent flexibility and adaptability. Amazon Robotics' robots can be seamlessly integrated into existing warehouse infrastructures without necessitating significant modifications, which reduces implementation costs and downtime.

Additionally, Amazon Robotics' systems occupy a smaller physical footprint compared to traditional conveyor or AS/RS systems. This is particularly beneficial for high-density warehouses where space optimization is crucial.

Amazon Robotics' robots are also capable of handling variable inventory sizes, shapes, and weights, with the capacity to manage loads up to 1,000 pounds. Their ability to adjust operations based on item specifications ensures versatility and efficiency across diverse product ranges.

Dematic vs Kiva Systems: Which is More Cost-Effective?

Cost is a pivotal consideration when choosing between Dematic and Kiva Systems. Generally, Amazon Robotics systems tend to be less expensive due to their lower upfront costs and reduced operating expenses. This cost efficiency stems from the minimal reliance on fixed materials handling equipment, such as conveyor belts, which lowers both capital and maintenance expenditures.

However, the total cost of ownership can vary based on specific warehouse requirements, the extent of system integration, and additional associated costs. For example, Dematic's comprehensive solutions might offer enhanced scalability and integration capabilities that justify their higher initial investment for larger operations.

Businesses must conduct a thorough cost-benefit analysis, considering both immediate and long-term financial implications, to determine the most cost-effective solution for their unique needs [4].

How Kiva Systems and Dematic are Revolutionizing the E-commerce Industry

Both Kiva Systems and Dematic are instrumental in transforming e-commerce operations by enabling more efficient and automated distribution centers. These advancements allow businesses to process orders at unprecedented speeds, meeting the escalating customer expectations for rapid delivery.

Kiva Systems, under Amazon Robotics, has been particularly influential in this transformation. Amazon's substantial investments in automation technology, including the expansion of Amazon Robotics, have facilitated global scalability and market penetration, enhancing order fulfillment capabilities [5].

Dematic’s solutions, known for their robustness and scalability, support large-scale e-commerce operations by integrating advanced robotics and software, ensuring seamless operations across diverse distribution networks.

The Role of Robotics in Warehouse Management

Robotic automation is revolutionizing warehouse management by enhancing operational efficiency, accuracy, and cost-effectiveness compared to traditional manual systems. Robots can operate continuously without fatigue, significantly increasing throughput and reducing error rates.

Moreover, modern robotic systems are designed to learn and adapt through machine learning algorithms, allowing continuous optimization of warehouse processes. This adaptability leads to shorter delivery times, higher accuracy, and sustained cost reductions over time [6].

Key Differences Between Kiva Systems and Dematic's Robotics Solutions

While both Kiva Systems and Dematic focus on warehouse automation, their approaches differ notably. Kiva Systems is renowned for its fleet of mobile robots that operate collaboratively in swarms, offering dynamic and flexible material handling solutions.

In contrast, Dematic emphasizes fixed materials handling equipment, such as conveyor belts and AS/RS, providing structured and scalable automation solutions suitable for large-scale operations.

Integration strategies also vary; Dematic has developed a suite of software solutions compatible with various systems, facilitating broader interoperability. Conversely, Amazon Robotics tends to prioritize proprietary software and hardware developments, ensuring tight integration within its ecosystem.

The choice between the two hinges on specific business requirements, including the desired level of flexibility, scalability, and existing infrastructure compatibility.

Choosing the Right Automation Partner for Your Business

Selecting the appropriate automation partner involves evaluating multiple factors, including cost, ease of integration, scalability, and reliability.

Businesses should seek partners with extensive experience in their industry, as this indicates a deeper understanding of unique operational challenges and requirements. Additionally, assessing the level of support and after-sales service is crucial to ensure long-term system performance and reliability.

Engaging with automation consultants or experts can provide valuable insights and assist in making informed decisions tailored to specific business needs [7].

Future Developments in Warehouse Automation: What to Expect from Kiva Systems and Dematic

The field of warehouse automation is poised for continual advancement, with both Kiva Systems and Dematic expected to lead innovation efforts. Kiva Systems, now Amazon Robotics, is anticipated to pioneer highly advanced robotic technologies capable of enhanced learning and adaptability, further optimizing warehouse operations.

Meanwhile, Dematic is projected to advance its software offerings, enabling greater integration and operational efficiency within warehouse environments. These developments will likely solidify both companies' positions as key industry players, driving the future of automated warehousing [8].

Case Studies: Successful Implementations of Kiva Systems and Dematic in Warehouses

Numerous successful deployments of Kiva Systems and Dematic technologies underscore their efficacy in warehouse automation. For example, Ocado, a leading online food retailer in Europe, implemented Kiva Systems to create a fully automated warehouse capable of processing up to 3.5 million items per week, enhancing operational efficiency and order accuracy [9].

In North America, PepsiCo leveraged Dematic's AS/RS and conveyor systems to establish a highly automated distribution center. This implementation enabled PepsiCo to accelerate order processing speeds and improve accuracy, demonstrating Dematic's capability to support large-scale, high-demand operations [10].

The Impact of Robotic Automation on Labor in Warehouses

The rise of warehouse automation has sparked discussions about its impact on labor. While there are concerns about potential job displacement, many experts argue that automation will create new employment opportunities as businesses expand and evolve.

Robots can take over repetitive and mundane tasks, allowing human workers to focus on more complex and cognitively demanding roles that require decision-making and problem-solving skills. This shift can lead to a more skilled and adaptable workforce, better suited to meet the challenges of modern warehousing.

Furthermore, training and development programs can equip employees with the necessary skills to manage and maintain automated systems, fostering a collaborative environment between humans and robots [11].

How to Evaluate Warehouse Automation Solutions for Your Business

When assessing warehouse automation solutions, consider the following key factors:

- Cost: Evaluate both initial investment and ongoing operational costs.

- Ease of Integration: Assess how easily the solution can be integrated with existing systems.

- Scalability: Ensure the solution can grow with your business needs.

- Reliability: Choose solutions with proven track records of performance and reliability.

- Customization: Consider the level of customization available to meet specific operational requirements.

- Support and Service: Ensure robust support and maintenance services are available.

Engaging with experienced consultants or automation partners can provide valuable guidance, helping businesses navigate the complexities of selecting and implementing the most suitable warehouse automation solutions [12].

Conclusion: Which Robotics Solution is Best for Your Business?

The decision to implement Kiva Systems or Dematic hinges on various factors, including specific business needs, budget constraints, and operational requirements.

Both companies offer robust and advanced automation solutions that can drive significant benefits. However, the optimal choice depends on the unique circumstances of each business. By thoroughly evaluating factors such as flexibility, scalability, cost-effectiveness, and integration capabilities, and by partnering with experienced automation experts, businesses can make informed decisions that position them for sustained success in the competitive realms of e-commerce and warehousing.

- Gartner Press Release on Supply Chain Automation

- Amazon Annual Reports

- Dematic Official Website

- Forbes: How to Evaluate Warehouse Automation Solutions

- Wall Street Journal: Amazon Robotics Impact

- McKinsey: The Future of Warehouse Automation

- Harvard Business Review: Choosing a Warehouse Automation Partner

- Forbes: Future of Warehouse Automation

- Ocado Case Study

- PepsiCo Automation Case Study

- Brookings: Impact of Robotics on Warehouse Labor

- SHRM: Evaluating Automation Solutions