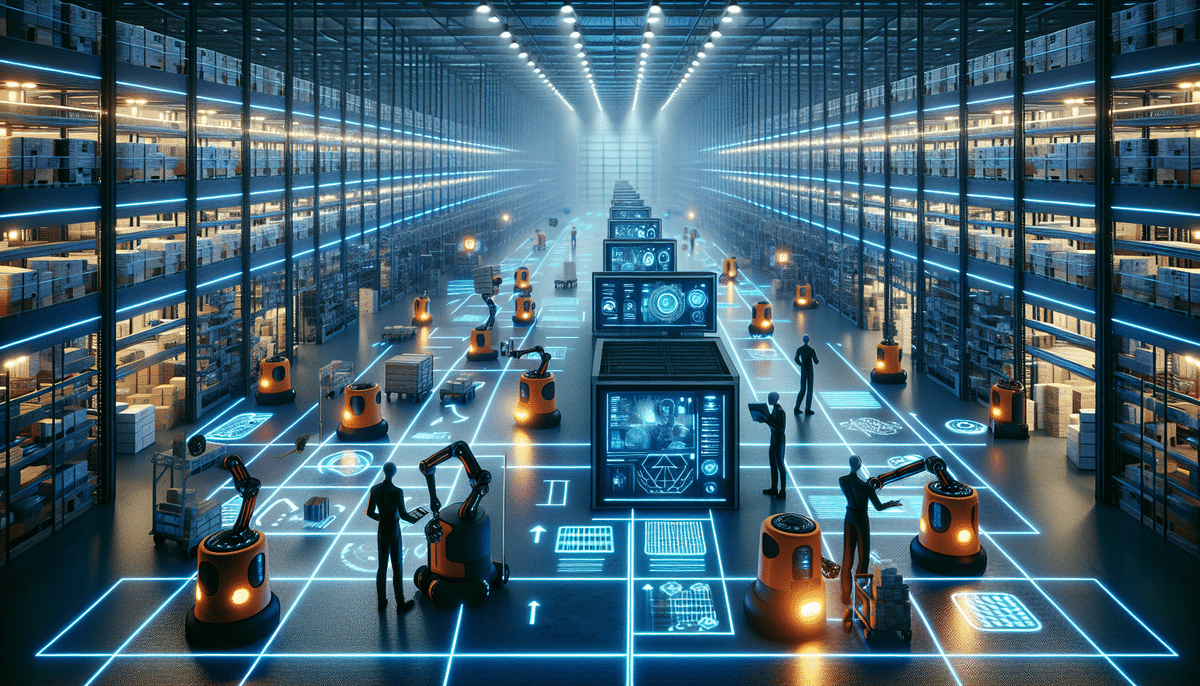

Introduction: The Rise of Automated Warehouses

Automated warehouses are revolutionizing the logistics industry by enhancing efficiency, reducing error rates, and minimizing the need for human intervention. As businesses increasingly invest in automation, a critical decision emerges: whether to implement Kiva Systems (now Amazon Robotics) or Locus Robotics. This article provides an in-depth analysis of these two leading robotic systems, highlighting their similarities, differences, and suitability for various warehouse operations.

Kiva Systems (Amazon Robotics) Overview

Kiva Systems, rebranded as Amazon Robotics, is a pioneer in warehouse automation. The system utilizes small, agile robots that transport inventory across the warehouse floor, significantly reducing manual handling. By seamlessly integrating hardware and software, Amazon Robotics coordinates robot movements to ensure maximum efficiency and adaptability, allowing businesses to scale operations as needed.

One of the primary advantages of Amazon Robotics is the substantial reduction in order fulfillment time. Robots handle the heavy lifting and transportation of goods, enabling warehouse workers to concentrate on tasks such as quality control and customer service. This division of labor not only accelerates order processing but also enhances overall customer satisfaction.

Additionally, Amazon Robotics offers remarkable flexibility in adapting to changing warehouse layouts. The robots are capable of navigating around obstacles and adjusting their routes to accommodate new products or fluctuating demand, helping businesses stay competitive in dynamic markets.

Locus Robotics Overview

Locus Robotics is a prominent player in the warehouse automation space, offering autonomous mobile robots that work collaboratively with human workers. Leveraging machine learning, computer vision, and decision science, Locus Robotics navigates warehouses and picks products with minimal human intervention. The system is renowned for its flexibility and scalability, making it suitable for a wide range of warehouse sizes and operations.

A key advantage of Locus Robotics is its adaptability to various warehouse layouts and inventory types. The robots can quickly learn and adjust to new environments, facilitating warehouse reconfigurations without disrupting ongoing operations. Moreover, Locus Robotics integrates seamlessly with existing warehouse management systems, ensuring smooth communication and coordination between robots and human workers.

Another significant benefit is the enhancement of worker safety. By automating the picking process, robots handle heavy or awkward items, reducing the risk of workplace injuries. Equipped with sensors and cameras, the robots are adept at detecting obstacles and avoiding collisions, fostering a safer warehouse environment.

Comparative Analysis: Kiva Systems vs Locus Robotics

Flexibility

- Kiva Systems: Offers high flexibility, ideal for businesses that frequently modify their warehouse layouts.

- Locus Robotics: Designed for collaboration with human workers, requiring fewer operational changes.

Scalability

- Kiva Systems: Suited for larger warehouses with high inventory volumes.

- Locus Robotics: Better suited for smaller warehouses with lower inventory levels.

Pricing Models

- Kiva Systems: Typically involves a higher upfront investment but lower ongoing costs.

- Locus Robotics: Requires a lower initial investment but may incur higher maintenance and support costs.

Design and Functionality

Kiva Systems features a simple design with small robots navigating flat surfaces, enabling streamlined and efficient warehouse layouts. This maximizes space utilization but limits the weight and size of items the robots can transport.

Locus Robotics employs more complex mobile robots that collaborate with human workers, allowing for greater flexibility in handling larger and heavier items. However, this may necessitate a more spacious warehouse layout to accommodate robot movements.

Performance

Both systems demonstrate high efficiency in warehouse operations. Kiva Systems excels at moving large volumes of inventory swiftly, optimized for grid-like warehouse layouts. In contrast, Locus Robotics enhances efficiency through effective collaboration with human workers and can navigate narrow aisles and tight spaces, making it more adaptable to warehouses with limited space.

Regarding maintenance, Kiva Systems requires a dedicated team of technicians for upkeep and repairs, which can be costly. Locus Robotics, with its modular design, allows for easier maintenance and repairs, reducing downtime and overall costs.

Usability

- Ease of Use: Kiva Systems is user-friendly with minimal training required. Locus Robotics may require more extensive training due to its complex and collaborative nature.

- Customization: Kiva Systems offers limited customization, suitable for businesses seeking straightforward solutions. Locus Robotics provides high levels of customization, allowing systems to be tailored to specific needs, though this may extend setup and implementation times.

- User Interface: Kiva Systems features an intuitive interface that is easy to navigate. Conversely, Locus Robotics offers a more complex interface with detailed information and control options for businesses requiring greater precision and control.

Pros and Cons

Kiva Systems (Amazon Robotics)

- Pros:

- Highly flexible and adaptable to changing business environments

- Reduces order fulfillment time

- Optimizes space utilization

- Cons:

- High initial investment cost

- Complex system requiring extensive employee training

- Potentially higher costs for system maintenance

Locus Robotics

- Pros:

- Collaborative design enhances worker productivity

- Highly scalable for business growth

- Flexible and adaptable to various warehouse layouts

- Cons:

- Requires more comprehensive employee training

- Potentially higher ongoing maintenance costs

- May need more spacious layouts to accommodate robot movements

Case Studies: Implementing Kiva Systems and Locus Robotics

Many companies have successfully integrated either Kiva Systems (Amazon Robotics) or Locus Robotics into their warehouse operations. For example, Amazon utilizes Amazon Robotics in its fulfillment centers, significantly boosting operational efficiency and order fulfillment speed. On the other hand, DHL has deployed Locus Robotics in its warehouses, reducing reliance on human intervention and enhancing overall efficiency and accuracy.

Future Trends in Automated Warehouses

The logistics industry continues to evolve, with automated warehouses leading the charge in innovation. Emerging technologies such as machine learning, computer vision, and artificial intelligence are set to drive further improvements in speed, accuracy, and efficiency. Future developments may include more advanced robotics, enhanced data analytics, and greater integration with Internet of Things (IoT) devices, paving the way for smarter and more responsive warehouse operations.

Conclusion: Choosing the Right Robotic System for Your Warehouse

Selecting between Kiva Systems (Amazon Robotics) and Locus Robotics depends on your warehouse's specific needs, budget, and scalability requirements. Amazon Robotics offers high flexibility and efficiency for larger operations, while Locus Robotics provides a collaborative and scalable solution suitable for smaller warehouses. Carefully assess your business requirements and operational goals to choose the system that best aligns with your objectives.