Introduction to Warehouse Automation: Kiva Systems (Amazon Robotics) vs Swisslog

Warehouse automation is revolutionizing business operations, with Kiva Systems (now Amazon Robotics after its acquisition) and Swisslog leading the charge. Both companies provide automated guided vehicles (AGVs) that enhance warehouse efficiency, but they differ in their approaches and technologies. This article delves into the histories of Kiva Systems and Swisslog, compares their AGV technologies, evaluates the benefits and cost-effectiveness of their solutions, examines the integration of artificial intelligence, and explores their adaptability to evolving e-commerce and omnichannel retail trends.

Company Histories and Origins

Kiva Systems (Amazon Robotics)

Kiva Systems was founded in 2003 in Massachusetts with a mission to transform warehouse operations through robotics. Their pioneering use of small, mobile robots to transport inventory eliminated the need for manual item retrieval, gaining rapid adoption by companies like Gap, Walgreens, and Staples. In March 2012, Amazon acquired Kiva Systems for $775 million, rebranding it as Amazon Robotics to further integrate advanced automation into their fulfillment centers.

Swisslog

Swisslog has a long-standing history in automation, dating back to 1900 when it was established as Schweizerische Warenhaus AG. Over the decades, Swisslog expanded its expertise into logistics, specializing in material handling and warehouse automation. The company focuses on optimizing space, time, and resources through their AGV solutions, presenting a viable alternative to traditional conveyor systems.

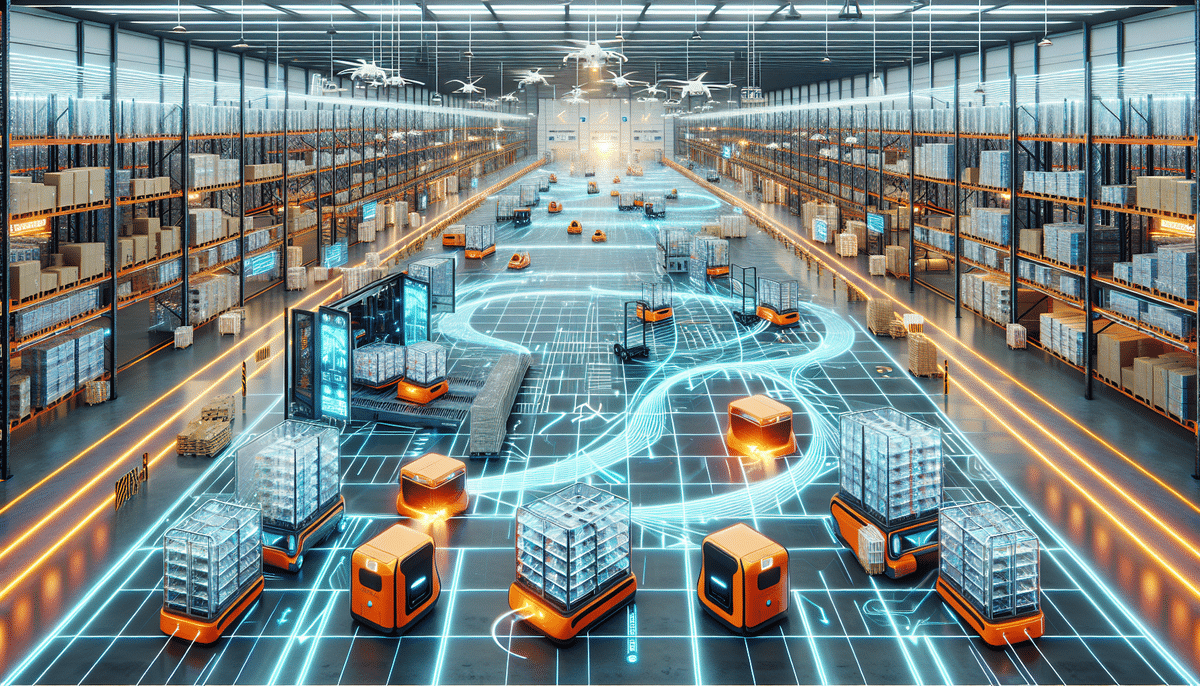

AGV Technologies: Kiva Systems vs Swisslog

Kiva Systems' AGV Technology

Kiva Systems, now Amazon Robotics, utilizes a centralized system to manage a fleet of small, motorized robots. These AGVs navigate the warehouse by following fixed pathways guided by barcode labels or wireless signals. The system efficiently directs robots to transport inventory to workers, streamlining the pick-and-pack process. Additionally, Kiva's modular design allows for easy upgrades and system reconfigurations to adapt to changing warehouse needs.

Swisslog's AGV Technology

Swisslog employs AGVs equipped with advanced laser sensors for precise navigation and obstacle avoidance. Their AGVs are designed to operate seamlessly in dense and varied warehouse environments, handling diverse loads such as pallets, carts, and custom containers. Swisslog's focus on flexibility ensures their AGVs can adapt to different terrains and warehouse layouts, maximizing speed and efficiency without extensive infrastructure investments.

Benefits and Advantages of AGVs

Efficiency and Productivity

Both Kiva Systems and Swisslog's AGVs significantly enhance warehouse efficiency by automating the movement of goods, reducing retrieval times, and minimizing human error. According to a McKinsey report, warehouses implementing AGVs can see productivity increases of up to 30%.

Cost-Effectiveness

Implementing AGVs from Kiva Systems and Swisslog can lead to substantial cost savings. Reduced labor costs, lower error rates, and optimized space utilization contribute to a favorable return on investment. A study by Gartner projects the global warehouse automation market to reach $30 billion by 2025, driven by cost-efficiency and scalability.

Safety and Flexibility

AGVs enhance workplace safety by handling repetitive and physically demanding tasks, reducing the risk of worker injuries. Additionally, the flexibility of AGV systems allows warehouses to adapt to fluctuating demands and evolving business models without significant downtime.

Real-World Implementations and Case Studies

Kiva Systems in Action

- PUMA: Transitioned to using Kiva robots, resulting in a 20% increase in inventory handling efficiency.

- Zulily: Implemented Kiva AGVs, reducing pick times by up to 60% and increasing order fulfillment accuracy.

Swisslog in Action

- Huawei: Adopted Swisslog's AGVs to handle large quantities of equipment, enhancing fulfillment center efficiency by 25%.

- Heineken: Utilized Swisslog AGVs to streamline their supply chain operations, resulting in faster turnaround times and reduced operational costs.

The Role of Artificial Intelligence in Warehouse Automation

Artificial intelligence (AI) and machine learning are pivotal in advancing AGV technologies:

- Kiva Systems (Amazon Robotics): Integrates AI to optimize robot coordination, predictive maintenance, and dynamic task allocation, enhancing overall system efficiency.

- Swisslog: Employs AI algorithms to refine routing, improve obstacle detection, and enable real-time adjustments based on warehouse conditions.

The integration of AI allows AGVs to become more intelligent and adaptive, facilitating smarter decision-making and autonomous operations in complex warehouse environments.

Adapting to E-Commerce and Omnichannel Retail Trends

With the exponential growth of e-commerce, warehouses must adapt to handle increased order volumes and diverse delivery requirements:

- Swisslog: Focuses on AI-powered AGV solutions that can analyze large data sets to provide actionable insights, enhancing inventory management and order processing.

- Amazon Robotics (Kiva Systems): Continues to innovate by integrating AGVs with other automation technologies, such as drones and autonomous vehicles, to support Amazon's expansive fulfillment network.

These adaptations ensure that AGV solutions remain aligned with the dynamic demands of modern retail and distribution channels.

Future Trends and Prospects in Warehouse Automation

The future of warehouse automation is promising for both Swisslog and Amazon Robotics:

- Kiva Systems (Amazon Robotics): Expanding into drone technology and autonomous delivery vehicles to further enhance the automation ecosystem.

- Swisslog: Investing in advanced AI and machine learning to develop more sophisticated AGV systems capable of handling increasingly complex warehouse tasks.

As e-commerce continues to grow and supply chains become more intricate, the demand for advanced automation solutions is expected to rise, positioning both companies as key players in shaping the future of warehouse operations.

Conclusion

Warehouse automation is a critical component of modern supply chain management, with Kiva Systems (Amazon Robotics) and Swisslog at the forefront of this transformation. Both companies offer robust AGV solutions that enhance efficiency, reduce costs, and improve safety in warehouse operations. While Kiva Systems excels in centralized, scalable systems tailored for high-demand environments like Amazon's fulfillment centers, Swisslog provides versatile and flexible AGV options suitable for a wide range of warehouse settings.

As technology advances, the integration of artificial intelligence and machine learning will further elevate the capabilities of AGVs, making warehouses smarter and more adaptive. Businesses looking to stay competitive in the rapidly evolving marketplace would benefit from implementing AGV solutions from either Kiva Systems or Swisslog, leveraging automation to drive operational excellence and support growth objectives.