Knapp vs 6 River Systems: A Comprehensive Comparison for Shopify-Integrated Warehouse Automation

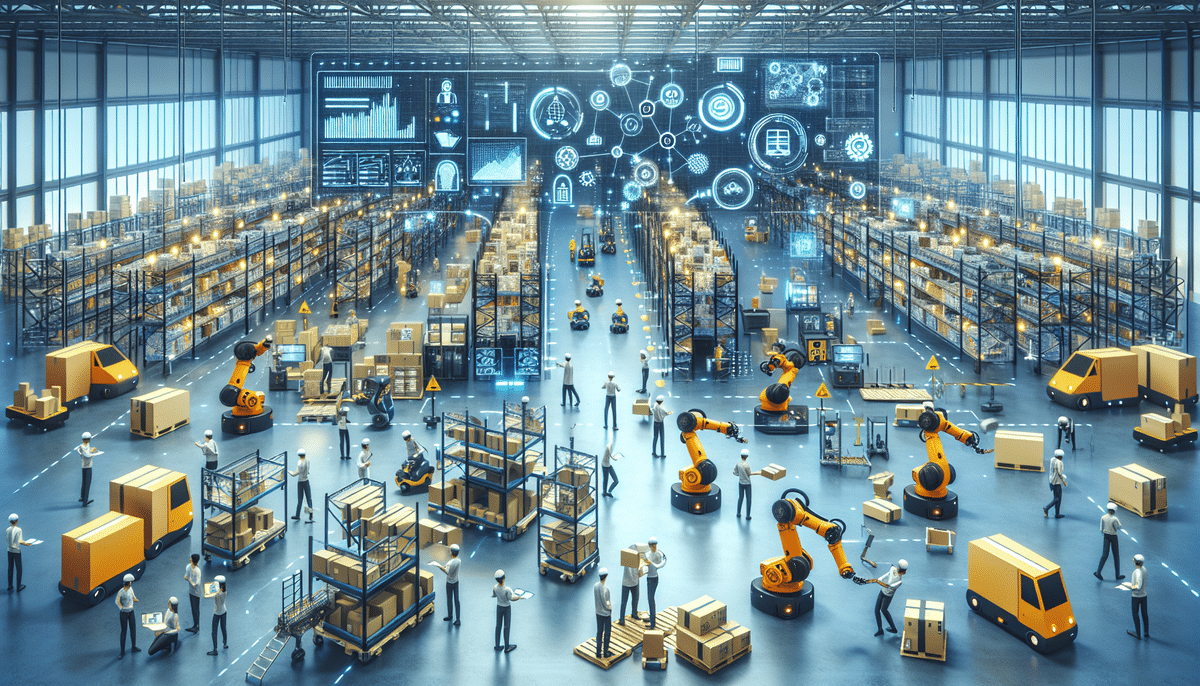

Warehouse automation is a pivotal component of modern supply chain management. Businesses are increasingly investing in automation systems to enhance operational efficiency and speed. Two of the leading players in this industry are Knapp and 6 River Systems. This article offers an in-depth comparison of these two systems, helping you determine which best suits your business needs.

An Introduction to Knapp and 6 River Systems

Knapp and 6 River Systems are renowned for their innovative warehouse automation solutions designed to boost productivity and efficiency. Leveraging cutting-edge technology, these systems optimize workflows and minimize errors.

Knapp is a Europe-based company with over 40 years of industry experience. It offers a wide range of automated storage and sorting systems suitable for businesses of all sizes. In contrast, 6 River Systems is an American company known for its collaborative mobile robot solutions tailored for warehouse fulfillment. Their system uniquely combines mobile robots with human workers, fostering a collaborative environment.

Both companies have successfully implemented their solutions across various industries, including retail, e-commerce, and healthcare. Notable clients of Knapp include Adidas, Coca-Cola, and Nestlé, while 6 River Systems has partnered with DHL and XPO Logistics. With the growing demand for warehouse automation, both companies continue to innovate to meet their clients' evolving needs.

Comparison Between Knapp and 6 River Systems

When comparing Knapp and 6 River Systems, several factors come into play:

- Scale of Operations: Knapp is ideal for larger, more complex operations, whereas 6 River Systems excels in smaller operations requiring high scalability.

- Level of Automation: Knapp offers advanced robotics and conveyor systems for high automation levels. In contrast, 6 River Systems focuses on collaborative robots that work alongside human workers.

- Implementation Time and Cost: Knapp typically has longer implementation times and higher upfront costs but may offer a greater return on investment for larger operations. 6 River Systems provides faster implementation and lower initial costs, making it more accessible for smaller businesses.

Integration with Shopify in Warehouse Automation

Integration with e-commerce platforms like Shopify plays a vital role in warehouse automation. Both Knapp and 6 River Systems integrate seamlessly with Shopify, allowing businesses to optimize their online sales channels alongside automated warehouse solutions.

This integration enables a streamlined order fulfillment process, where orders placed on Shopify are automatically sent to the warehouse system for processing and fulfillment. This reduces the need for manual intervention, minimizes errors, and enhances overall efficiency.

Moreover, Shopify's real-time inventory tracking, combined with the automated systems of Knapp and 6 River Systems, ensures that businesses maintain accurate stock levels, preventing issues like stockouts and overstocking.

Key Features and Benefits of Knapp

- High-speed storage and retrieval systems

- Optimized order picking with minimal human intervention

- Advanced warehouse management system

- Customizable solutions tailored to individual business needs

Knapp enhances warehouse efficiency and productivity through its high-speed storage and retrieval systems, significantly reducing the time required to locate and retrieve items. This leads to faster order fulfillment and increased customer satisfaction.

The advanced warehouse management system offered by Knapp provides real-time inventory tracking, ensuring businesses have accurate information about their stock levels. This capability helps prevent stockouts and overstocking, thereby avoiding lost sales and reducing costs.

Key Features and Benefits of 6 River Systems

- Collaborative mobile robots working alongside human workers

- Scalable solutions adaptable to changing business needs

- Real-time order tracking and fulfillment analytics

- Ease of use and fast implementation

6 River Systems offers intelligent task allocation, optimizing worker productivity and minimizing idle time. Their flexible integration capabilities allow seamless compatibility with existing warehouse management systems and other software platforms.

The collaborative robots from 6 River Systems enhance worker safety by automating repetitive and physically demanding tasks, allowing human workers to focus on higher-value activities that require human skills and judgment.

Functionality Differences Between Knapp and 6 River Systems

While both systems aim to provide automation and increased efficiency, they differ significantly in functionality:

- Knapp: Designed to manage complex warehouse operations with multiple simultaneous processes, handling high volumes of orders with minimal human intervention.

- 6 River Systems: Offers a user-friendly and scalable solution ideal for growing businesses with simpler operations.

Knapp provides highly customizable solutions, allowing businesses to tailor the system to their specific needs and processes, which is beneficial for operations with unique requirements. Conversely, 6 River Systems offers more standardized solutions suitable for businesses that do not require extensive customization.

Additionally, Knapp emphasizes robotics and automation, offering a wide range of robotic solutions for various warehouse tasks. This focus is advantageous for businesses aiming to reduce reliance on manual labor. On the other hand, 6 River Systems prioritizes human-robot collaboration, enhancing productivity and accuracy by integrating robots that work alongside human workers.

Cost Comparison Between Knapp and 6 River Systems

Knapp tends to be more expensive due to its complexity and extensive customization options. However, for larger companies with complex operations, the higher initial investment may translate into substantial long-term savings and efficiency gains.

6 River Systems offers a more affordable solution with lower upfront costs and faster implementation, making it an attractive option for smaller businesses with simpler operations. The cost-effectiveness of 6 River Systems ensures that businesses can achieve significant automation benefits without a hefty financial burden.

It's important to assess your specific business needs when comparing costs, as the value derived from each system can vary based on operational complexity and scale.

Customer Reviews of Knapp and 6 River Systems

Both Knapp and 6 River Systems receive positive reviews for their efficiency and reliability. However, some common feedback includes:

- Knapp: Praised for its advanced features and ability to handle complex operations, but criticized for its high cost and complexity.

- 6 River Systems: Appreciated for its user-friendly interface and affordability, though some users report occasional system glitches and limited customization options.

Despite these criticisms, many customers find Knapp's investment worthwhile due to its robust features and reliable customer support. Similarly, clients of 6 River Systems benefit from its ease of use and scalability, making it a dependable choice for efficient warehouse management.

Pros and Cons of Knapp vs 6 River Systems

When deciding between Knapp and 6 River Systems, consider the following advantages and disadvantages:

- Knapp:

- Pros: High level of customization, advanced technology, suitable for large operations.

- Cons: High cost, complex implementation.

- 6 River Systems:

- Pros: Ease of use, scalability, lower cost, fast implementation.

- Cons: Limited customization options, collaborative robots may not suit all warehouse types.

Case Studies: Implementing Knapp or 6 River Systems

Several companies have successfully implemented solutions from Knapp and 6 River Systems, yielding impressive results:

- Knapp: Implemented a solution for T-Mobile, resulting in a 300% increase in productivity.

- 6 River Systems: Provided a solution for Boxed, leading to a 200% increase in productivity and a 50% reduction in labor costs.

Future Trends in Warehouse Automation Industry

The future of warehouse automation is geared towards increased efficiency and scalability. Emerging trends include:

- Collaborative Robots: Continued emphasis on robots working alongside humans to enhance productivity.

- Advanced Analytics: Greater use of data analytics for real-time decision-making and process optimization.

- AI and Machine Learning: Integration of AI to predict demand, manage inventory, and optimize workflows.

Both Knapp and 6 River Systems are adapting to these trends. Knapp is likely to enhance its high-end customization and advanced robotics, while 6 River Systems may continue to innovate in human-robot collaboration and scalability. These trends will influence your choice based on how each system aligns with future advancements in warehouse automation.

Final Verdict: Choosing the Best System for Your Business

Determining the best system between Knapp and 6 River Systems depends on your specific business needs:

- Knapp: Best for extensive warehouse operations requiring high-speed automation and advanced technological solutions.

- 6 River Systems: Ideal for smaller operations seeking scalability, flexibility, and cost-effective automation.

In conclusion, both Knapp and 6 River Systems offer excellent warehouse automation solutions tailored to different business requirements. By carefully evaluating your operational needs, scale, and budget, you can make an informed decision on which system aligns best with your business goals.

For more information on choosing the right e-commerce platform for your business, visit our detailed guide on the e-commerce platforms.