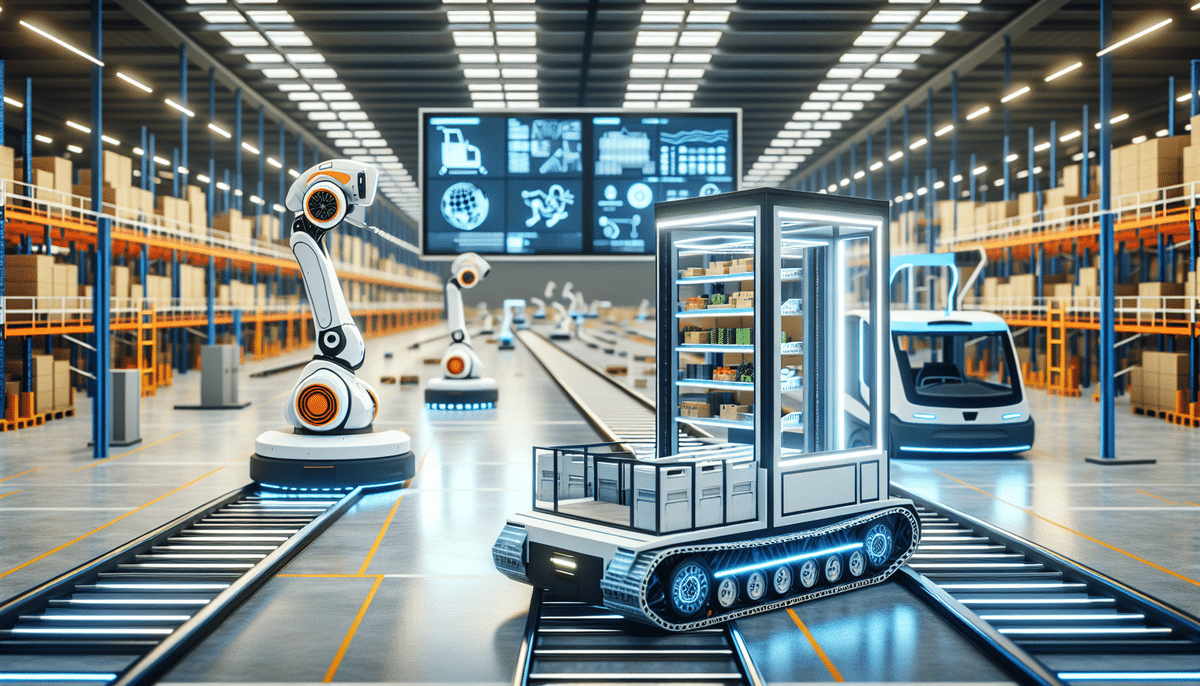

Knapp vs Dematic: Comprehensive Comparison of Leading Material Handling Solutions

When it comes to material handling solutions, Knapp and Dematic are among the top suppliers in the industry. Selecting the right system can significantly impact the efficiency of your operations, operational costs, and the quality of service delivered. This article provides a comparative analysis of Knapp and Dematic, examining their history, features, benefits, and drawbacks to help you determine which system best suits your business needs.

A Brief Overview of Knapp and Dematic

Knapp is an Austrian-based company renowned for its automation solutions across various industries, including healthcare, fashion, and retail. They specialize in designing and implementing fully automated warehouse systems, such as the Pick-it-Easy robot. With a global presence in over 35 countries, Knapp emphasizes research and development to stay at the forefront of innovation.

Dematic, headquartered in the United States, operates in over 25 countries worldwide. They offer a broad range of logistics solutions, including automated storage and retrieval systems (AS/RS), conveyors, palletizing systems, and more. Dematic serves diverse industries such as food and beverage, retail, and e-commerce, focusing on sustainability and environmental responsibility.

The History of Knapp and Dematic: A Comparative Analysis

Both Knapp and Dematic boast extensive histories in the material handling industry. Knapp, founded in 1952, has over seven decades of experience in providing innovative logistics solutions. In contrast, Dematic was established in 1819, making it one of the oldest companies in the sector with over two centuries of expertise.

Throughout their histories, both companies have demonstrated a commitment to innovation, quality, and customer satisfaction. They have received numerous awards for their products and services and are trusted by businesses worldwide. However, notable differences exist:

- Specialization: Knapp focuses primarily on automated warehouse solutions, while Dematic offers a broader range of material handling solutions, including conveyor systems, AGVs (Automated Guided Vehicles), and sortation systems.

- Market Presence: Knapp has a stronger foothold in Europe, whereas Dematic holds a larger market share in North America.

The Advantages and Disadvantages of Knapp and Dematic Solutions

Advantages of Knapp

- High Automation: Knapp's solutions are highly automated, reducing labor costs and increasing efficiency.

- Customization: Their systems are customizable to handle a wide range of products with speed and accuracy.

- Advanced Software: Integrated software enhances functionality, improving overall productivity.

- Sustainability: Features like energy-efficient lighting and automated shut-offs help reduce the carbon footprint.

Advantages of Dematic

- Versatility and Scalability: Dematic's solutions accommodate various warehouse sizes and budgets, making them suitable for both small and large businesses.

- Analytics Tools: In-built analytics allow real-time monitoring and optimization of operations.

- Sustainability Initiatives: Products like the Eco-friendly Accumulation Conveyor and Green AGV systems reduce energy consumption and operational costs.

Disadvantages of Knapp

- Higher Costs: Due to sophisticated technology, Knapp's systems are generally more expensive.

- Specialized Training Required: Operating Knapp's systems may require specialized training, adding to overall costs.

Disadvantages of Dematic

- Lack of High Customization: Dematic's systems may not be suitable for warehouses needing highly tailored solutions.

- Potential Limitations: Some systems are a compromise between automation and manual processes, which might limit certain operations.

Key Features of Knapp vs Dematic Systems: Which One is Right for You?

Both Knapp and Dematic offer unique features that set their systems apart:

Knapp's Key Features

- Cutting-Edge Software: Enables effortless tracking and management of inventory.

- Robotic Solutions: The Pick-it-Easy system efficiently handles a diverse range of items, from small medical supplies to large apparel orders.

Dematic's Key Features

- Diverse System Range: Includes conveyors, AGVs, AS/RS, and sortation systems.

- Modular Design: Allows businesses to scale operations up or down as needed.

If your business requires highly tailored or customized solutions, Knapp might be the optimal choice. Conversely, if versatility and scalability are your priorities, Dematic could be the better fit.

Both companies provide exceptional customer support and maintenance services. Knapp offers 24/7 expert support, ensuring minimal downtime, while Dematic provides comprehensive maintenance services, including remote monitoring and predictive maintenance to optimize system performance.

Efficiency Comparison: How Knapp and Dematic Equipment Differ in Productivity

Both Knapp and Dematic excel in operational efficiency, but they achieve it through different approaches:

- Automation Levels: Knapp's highly automated systems result in a lower error rate and faster processing times compared to Dematic's more manual processes.

- Productivity: Knapp's robotic solutions, like the Pick-it-Easy, can sort and pick items at impressive rates, significantly boosting productivity.

- Throughput: Dematic's systems handle multiple products simultaneously, enhancing throughput and reducing delivery times.

- Customization vs. Standardization: Knapp offers highly customizable systems tailored to specific needs, while Dematic's standardized systems facilitate quicker implementation and potentially lower costs.

Cost Comparison: Which System is More Affordable, Knapp or Dematic?

When evaluating the cost of Knapp vs. Dematic systems, several factors are essential:

- Initial Investment: Knapp's sophisticated technology generally makes their systems more expensive than Dematic's.

- Operating Costs: Dematic's systems typically have lower operating costs due to less automation complexity.

- Maintenance and Repair: Knapp requires specialized technicians, increasing maintenance expenses, whereas Dematic's systems are designed for easier maintenance, potentially saving costs over time.

- Scalability: Knapp offers highly scalable systems at a higher cost, while Dematic provides scalable solutions that may require customization, affecting overall expenses.

For small to medium-sized businesses, Dematic's solutions might be more cost-effective. However, if your operations demand high automation and scalability, the investment in Knapp's systems could be justified by the long-term efficiency gains.

Customer Support Services: How Do Knapp and Dematic Compare in After-Sales Support?

Effective customer support is crucial for the seamless operation of material handling systems. Both Knapp and Dematic offer robust after-sales support:

Knapp's Customer Support

- 24/7 technical support

- Global field service teams

- Comprehensive training and maintenance services

Dematic's Customer Support

- Extensive maintenance and repair services

- Training programs for operators

- Strong customer service culture with readily available support

One key difference is the response time: Knapp responds to customer queries within 15 minutes, whereas Dematic's response time is approximately 30 minutes. While both offer excellent support, Knapp's quicker response can enhance operational productivity by reducing downtime.

Case Studies: Real-World Examples of Successful Implementations of Knapp and Dematic Solutions

Understanding how Knapp and Dematic solutions perform in real-world scenarios can provide valuable insights:

Knapp Implementation

A leading e-commerce company integrated Knapp's automated storage and retrieval system, resulting in a 30% improvement in order fulfillment efficiency[^1]. The robotic system expedited delivery times, minimized errors, and significantly increased overall productivity.

Dematic Implementation

A major food and beverage company deployed Dematic's fully automated system to enhance inventory management. With Dematic's in-built analytics tools, the company achieved real-time stock monitoring, leading to more accurate inventory records and streamlined supply chain operations[^2].

Future Trends in Material Handling Solutions: The Role of Knapp vs. Dematic Systems

The future of material handling is set to be transformative, with emerging trends shaping the industry:

- Artificial Intelligence Integration: AI will further optimize operations, enhance predictive maintenance, and reduce downtime.

- Internet of Things (IoT): IoT devices will enable more connected and intelligent systems.

- Robotic Automation: Increased use of robots for sorting, picking, and transportation tasks.

Knapp is at the forefront of integrating AI, with solutions like the KiSoft Vision software, which utilizes image recognition to enhance the accuracy of pick and pack operations, thereby boosting productivity.

Dematic continues to emphasize scalable and modular solutions, allowing their systems to be easily customized and reconfigured to meet evolving business needs. This flexibility is crucial for businesses seeking adaptable and future-proof material handling solutions.

Conclusion

Choosing the right material handling solution is pivotal for the efficiency and success of your business operations. Both Knapp and Dematic are reputable suppliers offering a wide array of solutions tailored to different needs. When deciding between them, consider factors such as:

- Budget

- Warehouse Size

- Required Level of Automation

- Customization Needs

- Customer Support Services

By evaluating these aspects, you can make an informed decision that aligns with your business objectives and operational requirements.