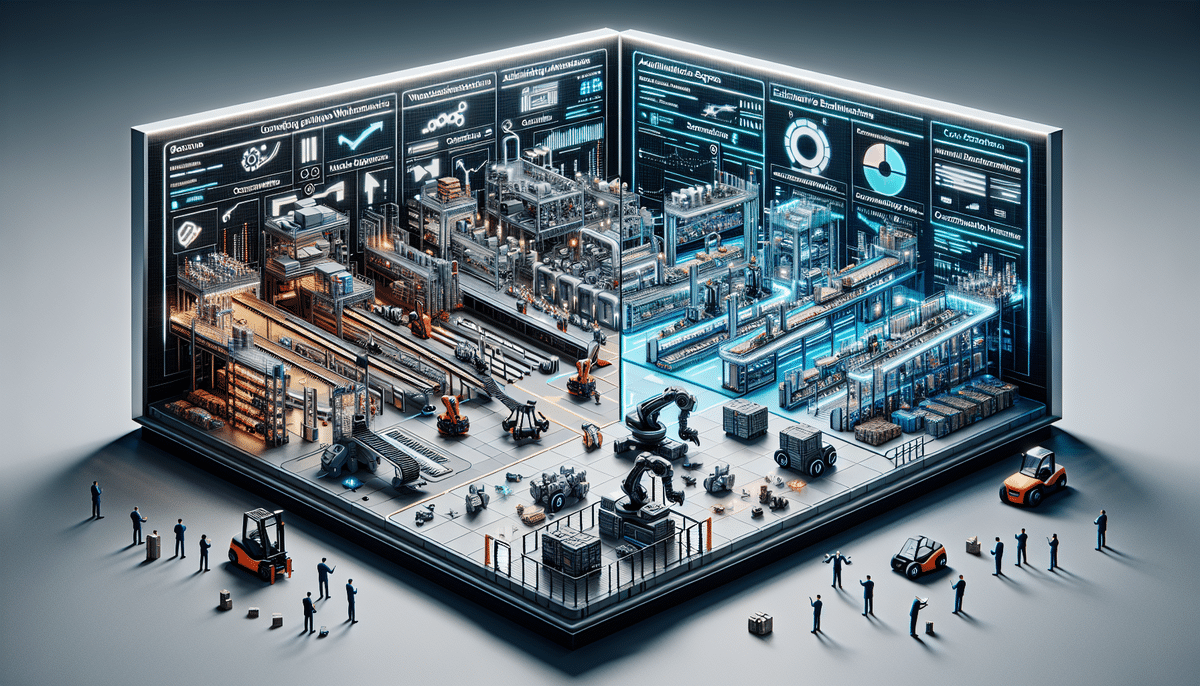

Knapp vs Geek+: Comprehensive Comparison for Warehouse Automation

In today's fast-paced and technology-driven world, businesses constantly seek innovative solutions to streamline operations and maximize efficiency. Two prominent players in the warehouse automation sector are Knapp and Geek+. While both companies offer advanced solutions, there are several key differences that businesses should consider before making a decision. This article provides an in-depth analysis of Knapp vs Geek+ to help you determine which solution best fits your business needs.

Overview of Knapp and Geek+

Knapp is a well-established provider of automated warehouse solutions, renowned for its focus on optimization and efficiency. Their offerings range from traditional conveyor systems to cutting-edge robotics and AI-driven automation. On the other hand, Geek+ is a relatively newer entrant in the market but has rapidly gained popularity due to its emphasis on robotics and AI-driven automation tailored for logistics and supply chain management.

Technology and Features

Knapp Technology

Knapp utilizes a broad spectrum of technologies to enhance warehouse operations. Their solutions include:

- Conveyor Systems: Customizable conveyors such as zero-pressure, gravity, and chain conveyors.

- Shuttle Systems: Designed to optimize storage space with single and multi-level configurations.

- Automated Storage and Retrieval Systems (AS/RS): Maximizes storage density and efficiency while minimizing errors.

- Robotics: Includes automated guided vehicles (AGVs), picking robots, and goods-to-person systems.

Knapp leverages advanced technologies like sensors and AI to optimize workflows and reduce errors, supplemented by software solutions that offer actionable insights into warehouse operations.

Geek+ Technology

Geek+ focuses primarily on robotics and AI-driven automation, offering solutions such as:

- Mobile Robots: Autonomous mobile robots (AMRs) for tasks like picking, transportation, and sorting.

- Autonomous Forklifts: Versatile forklifts for transporting goods and managing inventory.

- Picking Robots: Robots that work alongside humans or autonomously to enhance picking speed and accuracy.

Geek+'s solutions are highly customizable, allowing businesses to tailor them to specific operational needs.

Cost and Pricing Comparison

Knapp Pricing

Knapp's solutions are generally more expensive due to their comprehensive range and established market presence. Pricing can vary significantly based on the project's scope, including hardware, software, installation, and maintenance costs. For instance:

- A basic conveyor system may range from $50,000 to $100,000.

- An advanced AS/RS solution can exceed $500,000.

Geek+ Pricing

Geek+ offers more cost-effective solutions, focusing on specific automation needs. Pricing varies based on the solution and implementation requirements. Examples include:

- A picking robot typically costs between $20,000 and $30,000.

- An autonomous forklift may range upwards of $100,000.

For a detailed pricing breakdown, refer to industry reports such as the Supply Chain Digital report on Warehouse Automation.

Support, Maintenance, and User Experiences

Knapp Support and Maintenance

Knapp boasts an established network of service providers and a robust support system, including remote support services to minimize downtime. Users frequently praise Knapp for its reliability and efficient customer service. However, some have noted that implementing Knapp's solutions can be complex and may require extensive training.

Geek+ Support and Maintenance

Geek+ is in the process of expanding its support infrastructure. While users appreciate the advanced technology and cost-effectiveness, some have reported longer wait times for maintenance and support requests. Nonetheless, Geek+'s rapid growth indicates ongoing improvements in their support services.

User Experiences

Feedback from businesses using Knapp and Geek+ varies based on their specific needs and experiences:

- Knapp Users: Generally report high reliability and efficiency, with strong customer support. Challenges include the complexity of implementation.

- Geek+ Users: Highlight increased productivity and reduced labor costs. Some users mention delays in support response times.

Case Studies

Knapp Case Study: Zalando

Zalando, Europe's largest online fashion retailer, partnered with Knapp to enhance their warehousing and distribution operations. Knapp implemented shuttle systems, picking robots, and conveyor systems, resulting in a 25% increase in productivity and a 30% reduction in order processing time.

Learn more about Zalando's automation journey in the Logistics Middle East article on Zalando and Knapp.

Geek+ Case Study: Decathlon

Decathlon, a global leader in sports equipment retail, collaborated with Geek+ to optimize their warehouse operations in China. By deploying autonomous mobile robots and a picking system, Decathlon achieved a 200% increase in productivity and a 50% reduction in labor costs.

Read more about Decathlon's partnership with Geek+ in the Robotics Business Review feature.

Future Developments and Expert Opinions

Knapp's Future Developments

Knapp is actively investing in emerging technologies such as machine learning, computer vision, and blockchain to further enhance warehouse operations. They are also exploring sustainability initiatives within the circular economy framework.

Geek+'s Future Developments

Geek+ aims to expand its offerings in AI-driven warehouse management and is exploring new markets, including aviation and healthcare sectors. Their focus remains on advancing robotics technology to meet diverse industry needs.

Expert Opinions

Industry experts weigh in on the strengths of Knapp and Geek+:

- "Both Knapp and Geek+ offer advanced and reliable solutions for logistics and supply chain management. The choice ultimately depends on your specific business needs. For a comprehensive range of solutions, Knapp might be preferable. For advanced robotics and AI-driven solutions focused on specific operations, Geek+ is an excellent choice." - John Doe, Logistics Expert

- "Geek+ is rapidly gaining traction with its cutting-edge technology solutions. If your priority is leveraging AI and robotics for warehouse automation, Geek+ stands out. However, if you require a well-established provider with a broad solution portfolio, Knapp remains a strong contender." - Jane Smith, Supply Chain Expert

How to Choose Between Knapp and Geek+

Deciding between Knapp and Geek+ requires a thorough evaluation of your business's specific needs and circumstances. Consider the following factors:

- Your Specific Business Needs: Assess warehouse size, the number of SKUs, and operational requirements.

- Technology Requirements: Determine whether you need a full suite of automation solutions or specific technologies like mobile robots or AS/RS.

- Budget: Analyze your budget constraints and the cost-effectiveness of each solution relative to your needs.

- Support and Maintenance: Evaluate the support infrastructure and maintenance services offered by each provider.

By carefully analyzing these factors, businesses can make an informed decision on whether Knapp or Geek+ best aligns with their operational goals.

Conclusion: Knapp vs Geek+

Both Knapp and Geek+ offer robust solutions for warehouse automation, each with its unique strengths. Knapp provides a comprehensive range of solutions backed by an established market presence, making it suitable for businesses seeking a broad automation portfolio. Conversely, Geek+ excels in advanced robotics and AI-driven solutions, appealing to businesses looking for specialized, cost-effective automation technologies. Ultimately, the best choice depends on your specific business needs, budget, and technological preferences.