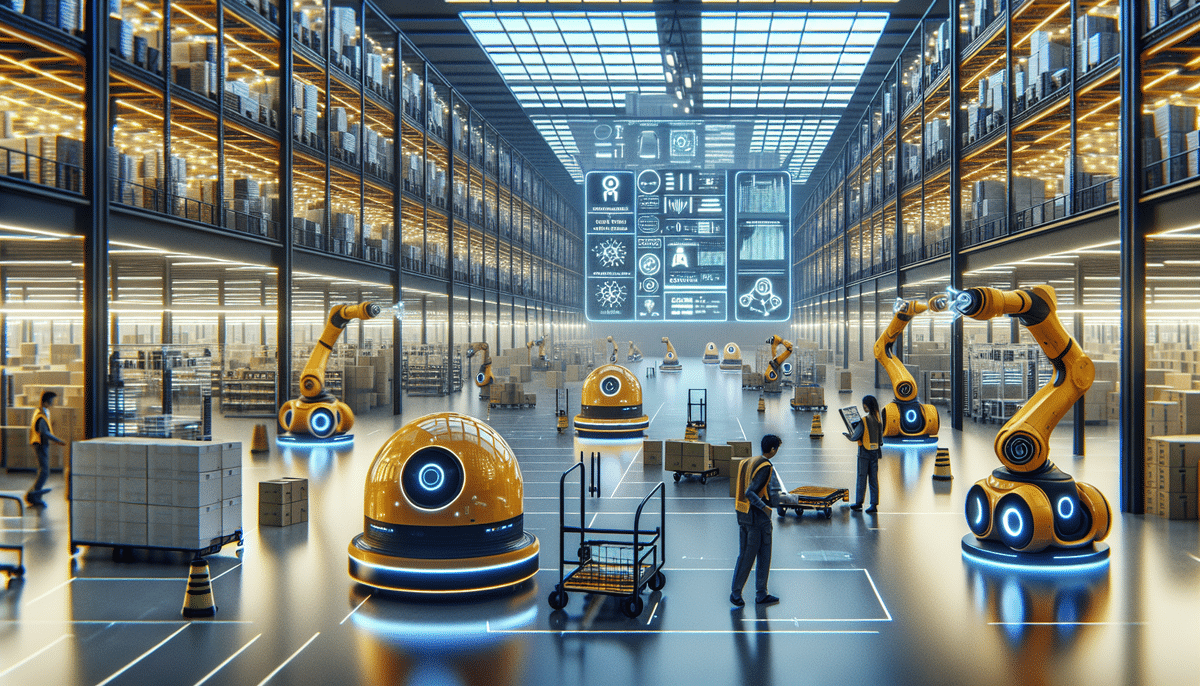

Knapp vs Amazon Robotics: Leading the Warehouse Automation Revolution

In the rapidly evolving landscape of warehouse automation, two companies have emerged as frontrunners due to their cutting-edge technologies and impressive track records: Knapp and Amazon Robotics (formerly Kiva Systems). These industry leaders have transformed warehouse operations by implementing advanced robotic solutions that optimize processes, reduce costs, and boost productivity. This article provides an in-depth comparison of Knapp and Amazon Robotics, examining their histories, technological innovations, benefits, and costs to help businesses make informed decisions about their warehouse management strategies.

History and Evolution of Knapp and Amazon Robotics

Knapp's Journey in Logistics Automation

Founded in Austria in 1952 as a small carpentry shop, Knapp has grown into a global powerhouse in logistics automation with over four decades of expertise. Knapp's early innovations in automated storage and retrieval systems set the foundation for its expansive product portfolio, which now includes shuttle systems, conveyor systems, and robotics. Recent advancements include the OSR Shuttle Evo, an advanced automated storage and retrieval system, and the AI-powered Pick-it-Easy Robotics, which integrates robotic arms with artificial intelligence to enhance order picking efficiency and accuracy. Knapp's commitment to sustainability is evident in its energy-efficient products and services, such as systems that reduce energy consumption and minimize packaging waste.

Amazon Robotics' Transformation from Kiva Systems

Amazon Robotics originated as Kiva Systems, founded in 2003 in the United States. Kiva's groundbreaking Automated Guided Vehicles (AGVs) revolutionized warehouse logistics by efficiently moving heavy materials within storage facilities. Amazon's acquisition of Kiva Systems in 2012 for $775 million marked a significant milestone, integrating Kiva's technology into Amazon's vast logistics network. This acquisition accelerated the development and deployment of Amazon Robotics' Autonomous Mobile Robots (AMRs), designed to navigate warehouses autonomously, delivering goods to human pickers at packing stations. These robots enhance flexibility, scalability, and adaptability, allowing warehouses to efficiently handle fluctuating demand and maintain high operational standards.

Technological Innovations and Functionalities

Knapp's Automation Solutions

Knapp offers a range of automated solutions tailored to various industries, including automated storage and retrieval systems, shuttle systems, and conveyor systems. The OSR Shuttle Evo utilizes intelligent algorithms and advanced sensors to optimize order fulfillment, inventory management, and shipping processes. Additionally, Knapp's Pick-it-Easy Robotics leverages robotic arms combined with artificial intelligence to ensure precise and efficient order picking, significantly reducing errors and increasing throughput.

Amazon Robotics' Autonomous Mobile Robots

Amazon Robotics specializes in Autonomous Mobile Robots (AMRs) that operate seamlessly alongside human workers. These AMRs are equipped with sophisticated navigation systems, allowing them to move freely within the warehouse, dynamically adjust their routes, and handle diverse tasks such as inventory counting and restocking. This flexibility reduces the need for fixed infrastructure and enables warehouses to scale operations effortlessly in response to changing demands.

Comparative Technological Approaches

The primary distinction between Knapp and Amazon Robotics lies in their technological methodologies. Knapp's systems are predominantly stationary, operating on fixed schedules with robots following predefined paths. This approach ensures high precision and control but requires extensive planning and infrastructure. Conversely, Amazon Robotics' AMRs offer unparalleled flexibility, navigating warehouses dynamically and adapting to real-time demand changes without the need for extensive upfront planning. While Knapp's robots excel in structured environments with predictable workflows, Amazon Robotics' AMRs are ideal for dynamic settings requiring agility and scalability.

Benefits of Warehouse Automation with Knapp and Amazon Robotics

- Increased Productivity: Automation enables the processing of a higher volume of orders in less time, which is particularly advantageous for e-commerce businesses handling numerous small items.

- Reduced Human Error: Automated systems enhance accuracy, leading to fewer order discrepancies and returns, thereby improving customer satisfaction.

- Improved Safety: Robots can handle hazardous materials and heavy loads, reducing the need for manual labor and minimizing workplace injuries.

- Cost Savings: Automation lowers labor costs and boosts operational efficiency, resulting in significant long-term savings.

- Scalability: Robotic systems can be scaled up or down based on demand, allowing businesses to adapt quickly to market fluctuations.

Success Stories: Implementations of Knapp and Amazon Robotics

Case Study: Calzedonia

Calzedonia, an Italian fashion retailer, integrated Knapp's OSR Shuttle Evo and Pick-it-Easy Robotics into its warehouse operations. This implementation led to a 50% reduction in picking time and increased accuracy to 99.9%, significantly enhancing operational efficiency and customer satisfaction.

Case Study: Zulily

Zulily, an online retail platform, deployed Amazon Robotics' AMRs within its warehouses. The adoption of these robots resulted in an 80% decrease in picking time and a fourfold increase in productivity, demonstrating the substantial impact of robotics on warehouse performance.

Other Notable Implementations

- Staples implemented Knapp's automation solutions, achieving enhanced inventory management and order accuracy.

- Walgreens utilized Amazon Robotics' AMRs to streamline its distribution centers, resulting in faster order processing and reduced operational costs.

- Symbotic adopted both Knapp and Amazon Robotics' technologies to optimize its supply chain, leading to improved throughput and scalability.

Impact of COVID-19 on Robotics Adoption in Warehouse Operations

The COVID-19 pandemic acted as a catalyst for the accelerated adoption of robotics in warehousing and logistics. With the surge in online shopping and the necessity to minimize human contact, businesses turned to automation to maintain operational continuity and meet increased demand. Robotic systems proved invaluable in handling higher order volumes efficiently while ensuring worker safety.

Enhancing Resilience and Adaptability

The pandemic highlighted the importance of resilient and adaptable supply chains. Robotics enabled warehouses to scale operations quickly in response to fluctuating demands and disruptions, ensuring consistent service delivery despite unprecedented challenges.

Future Implications

The experiences gained during the pandemic have underscored the critical role of automation in building robust supply chains. As a result, the adoption of robotics is expected to continue growing, with businesses investing in advanced technologies to enhance their resilience and adaptability in the face of future disruptions.

The Future of Robotics in Warehousing: Challenges and Opportunities

Emerging Trends

The future of robotics in warehousing is poised for significant growth, driven by advancements in artificial intelligence, machine learning, and data analytics. These technologies will further enhance the capabilities of robotic systems, enabling more sophisticated decision-making and autonomous operations.

Challenges to Overcome

- High Implementation Costs: The initial investment required for robotic systems remains a barrier for many small to medium-sized enterprises.

- Maintenance Expertise: Advanced robotic systems require specialized skills for maintenance and operation, necessitating investment in training and development.

- Job Displacement Concerns: Automation may lead to the reduction of certain job roles, raising concerns about workforce displacement and the need for reskilling.

Opportunities Ahead

Despite these challenges, the opportunities presented by robotics are substantial. Enhanced profitability, improved customer satisfaction, and scalable operations are key benefits that drive businesses to invest in automation. Moreover, the integration of robotics with other emerging technologies will unlock new possibilities for optimizing warehouse operations and supply chain management.

Choosing the Right Robotics Partner: Knapp vs Amazon Robotics

Selecting the appropriate warehouse automation partner is crucial for achieving operational excellence. Key factors to consider include:

- Type of Goods Handled: The nature of the inventory influences the choice of automation solutions, with some systems better suited for specific types of products.

- Order Volume and Frequency: High-volume operations may benefit from scalable systems capable of handling large order quantities efficiently.

- Complexity of Operations: Complex workflows may require highly customizable and precise robotic systems to meet specific operational needs.

- Customization Needs: The level of customization required to align the robotic system with business processes is a critical consideration.

- Cost-Benefit Analysis: Evaluating the upfront investment, ongoing maintenance costs, and potential return on investment is essential for making an informed decision.

In terms of functionality, Knapp is ideal for businesses with highly structured and predictable operations that demand high accuracy and precision. On the other hand, Amazon Robotics offers solutions that are better suited for dynamic environments requiring flexibility and scalability to adapt to evolving demands. Ultimately, the choice between Knapp and Amazon Robotics should align with the specific needs and strategic objectives of the business.

Comparing the Cost-Effectiveness of Knapp and Amazon Robotics vs Traditional Warehouse Management Systems

When assessing the cost-effectiveness of Knapp and Amazon Robotics, it's important to consider several factors in comparison to traditional Warehouse Management Systems (WMS):

- Upfront Investment: Robotic systems generally require a higher initial investment compared to traditional WMS due to the cost of hardware and implementation.

- Long-Term Savings: Over time, reductions in labor costs and increases in productivity can offset the initial expenditures, making automation a cost-effective solution in the long run.

- Scalability: Robotic systems offer greater scalability, allowing businesses to expand operations seamlessly as demand grows without significant additional investments.

- Operational Efficiency: Enhanced accuracy and speed provided by robotic systems improve overall operational performance, leading to potential revenue growth and increased profitability.

While the initial costs of implementing Knapp and Amazon Robotics' systems are higher, the long-term benefits—including reduced labor expenses, improved efficiency, and scalable operations—often result in greater cost savings compared to traditional WMS. Businesses with high order volumes and the need for scalable solutions stand to gain the most from investing in robotic automation.

Conclusion

As businesses strive to optimize warehouse operations and stay competitive in a dynamic market, the adoption of robotic automation presents a compelling solution. Knapp and Amazon Robotics are at the forefront of this transformation, each offering unique technologies, benefits, and cost structures tailored to different operational needs.

By understanding the distinct offerings of Knapp and Amazon Robotics, businesses can make informed decisions that align with their specific requirements and strategic goals. Implementing the right robotic system can lead to significant improvements in productivity, accuracy, and efficiency, paving the way for sustained success and growth in the competitive landscape of warehouse management.