Knapp vs Locus Robotics: An In-Depth Comparison

In 2023, the logistics industry continues to evolve rapidly, driven by the necessity to enhance efficiency and meet growing consumer demands. As businesses strive to stay competitive, the adoption of advanced robotic solutions has become paramount. Among the leading providers in this space are Knapp and Locus Robotics. This article offers a comprehensive analysis of Knapp and Locus Robotics, aiding you in determining the most suitable solution for your business requirements.

Table of Contents

- Overview of Knapp and Locus Robotics

- Robotic Solutions and Technologies

- Comparative Analysis: Features, Benefits, and Cost

- Implementation and Operational Considerations

- Cost Comparison

- Impact on Efficiency and Productivity

- Case Studies: Success Stories

- Future Developments

- Final Verdict

Overview of Knapp and Locus Robotics

Knapp is an Austrian-based company with over 60 years of experience in the logistics automation industry. Specializing in logistics systems and software services, Knapp serves sectors such as retail, eCommerce, and healthcare. Their extensive portfolio includes Automated Storage and Retrieval Systems (ASRS), automated sortation systems, and more, designed to optimize warehouse operations.

In contrast, Locus Robotics, headquartered in the United States, focuses on Autonomous Mobile Robots (AMR) for warehouse logistics. The company's flagship product, LocusBot, is engineered to collaborate seamlessly with human workers, enhancing productivity and operational efficiency.

Both companies are at the forefront of the logistics industry, offering innovative solutions that address the challenges of modern warehousing. With the global eCommerce market projected to exceed $6.54 trillion by 2023 according to [eMarketer](https://www.emarketer.com/content/global-ecommerce-sales-2023), the demand for efficient logistics solutions from providers like Knapp and Locus Robotics is more critical than ever.

Robotic Solutions and Technologies Offered by Knapp and Locus Robotics

Knapp's Robotic Solutions

Knapp provides a spectrum of semi-automated and fully-automated warehouse solutions tailored for material handling, storage, and order fulfillment. Key products include:

- Shuttle Systems: Capable of handling up to 1,000 kg per tray, ideal for storing heavy items like automotive parts.

- Pocket Sorters: Efficiently sort a high volume of items, reducing manual sorting errors.

- Automated Guided Vehicles (AGVs): Streamline the movement of goods within the warehouse.

Knapp's modular systems allow for scalability, enabling businesses to adapt and expand their operations as needed.

Locus Robotics' Solutions

Locus Robotics specializes in Autonomous Mobile Robots (AMR) that operate alongside human workers to enhance warehouse activities such as:

- Picking: Robots navigate the warehouse to retrieve items efficiently.

- Replenishment: Automated restocking of inventory shelves.

- Order Fulfillment: Streamlining the process from picking to packing.

The integration of machine learning and computer vision technologies in LocusBots allows them to navigate complex environments, optimize routes, and adapt to dynamic warehouse conditions.

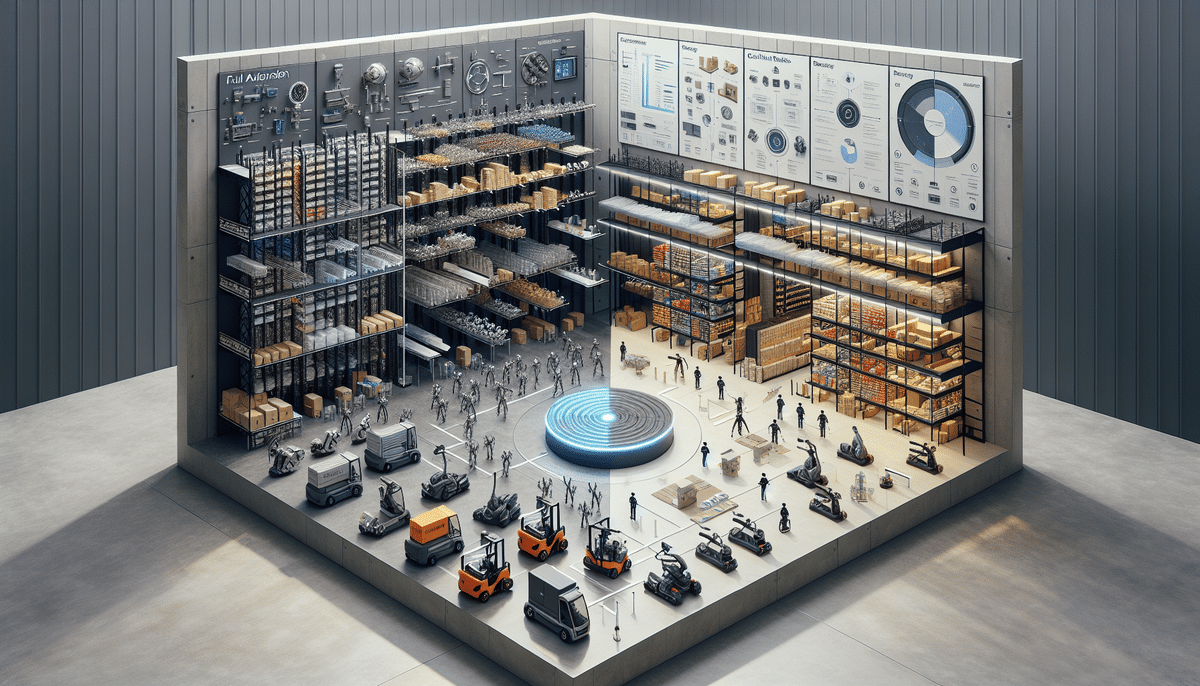

Comparative Analysis: Features, Benefits, and Cost

Automation Level

Knapp offers comprehensive automation solutions suitable for large-scale operations requiring full automation. Their systems minimize human intervention, thereby reducing labor costs and increasing operational speed.

Locus Robotics provides a hybrid approach, combining autonomous robots with human workers. This is ideal for businesses looking to enhance productivity without fully automating their operations.

Scalability and Flexibility

- Knapp: Highly customizable and scalable, suitable for warehouses of varying sizes and complexities.

- Locus Robotics: Easily scalable with a subscription-based model, allowing for quick deployment across different warehouse sizes.

Pricing Models

Knapp typically follows a traditional pricing structure, involving significant upfront investments for hardware and software, along with ongoing maintenance fees.

Locus Robotics adopts a subscription-based pricing model, enabling businesses to manage costs more effectively without large initial expenditures.

Customer Support

- Knapp: Comprehensive support with dedicated teams of technicians and engineers.

- Locus Robotics: Emphasizes self-service with extensive documentation and online resources.

Implementation and Operational Considerations in Warehouse Settings

Knapp

Implementing Knapp's solutions requires detailed planning and substantial capital investment. The installation process can span several months, but results in unparalleled speed and accuracy in warehouse operations. Post-implementation, businesses benefit from reduced errors and increased throughput.

Locus Robotics

Locus Robotics offers a more straightforward setup, with plug-and-play robots that can be operational within hours. However, optimizing their performance may necessitate adjustments to the warehouse layout and the establishment of charging stations.

Both solutions demand trained personnel for effective operation and maintenance. While Locus Robotics may require less specialized training, Knapp's complex systems may necessitate hiring or training specialized staff.

Cost Comparison

When evaluating costs, Knapp's solutions are typically more expensive due to their comprehensive automation capabilities. Prices can range from $500,000 to several million dollars, depending on the system's scale and complexity.

Locus Robotics offers a more affordable alternative, with robots priced between $20,000 to $30,000 per unit. Their subscription-based model further reduces barriers to entry, making it a cost-effective choice for many businesses.

However, for large-scale operations with high order volumes, Knapp's fully automated systems may offer greater long-term cost savings by significantly reducing labor costs and increasing efficiency.

Additionally, Knapp's highly customizable solutions can cater to specific business needs, potentially offering better value for companies requiring tailored automation.

Impact on Warehouse Efficiency and Productivity

Both Knapp and Locus Robotics significantly enhance warehouse efficiency and productivity:

- Knapp: Full automation leads to faster processing times and higher accuracy levels, minimizing errors in order fulfillment.

- Locus Robotics: Enables human workers to focus on complex tasks while robots handle repetitive activities, boosting overall productivity.

Implementing these robotic solutions results in reduced labor costs, fewer operational errors, and accelerated delivery times. This not only improves business profitability but also enhances customer satisfaction through faster and more reliable service.

Moreover, the integration of robotics contributes to a safer work environment by taking over physically demanding and repetitive tasks, thereby reducing the risk of workplace injuries.

Case Studies: Success Stories with Knapp and Locus Robotics

Knapp

Aldi, one of Germany's largest discount supermarket chains, implemented Knapp's automation systems to streamline their logistics operations. The adoption led to a 30% reduction in warehousing costs and a significant increase in supply chain efficiency, as reported in [Knapp’s official case studies](https://www.knapp.com/en/case-studies).

GEODIS, a global logistics provider, utilized Knapp's ASRS to enhance their order fulfillment process, resulting in faster processing times and improved customer satisfaction.

Locus Robotics

DHL, a leading global logistics company, integrated Locus Robotics into their warehouse operations. This implementation led to a 300% increase in productivity and a near elimination of picking errors, as detailed in their [DHL case study](https://www.locusrobotics.com/resources/case-studies).

Quiet Logistics, a third-party logistics provider, deployed LocusBots to optimize their picking and packing processes, achieving faster order processing times and enhanced accuracy.

Future Developments: Advancements in Knapp and Locus Robotics Technology

Both Knapp and Locus Robotics are continually innovating to stay ahead in the competitive logistics automation market:

- Knapp: Investing in data analytics, IoT integration, and artificial intelligence to further optimize warehouse operations and enable predictive maintenance.

- Locus Robotics: Developing more agile robots capable of navigating diverse terrains and complex warehouse layouts. Additionally, they are expanding robot functionalities to include inspection, quality control, and advanced packing capabilities.

These advancements aim to provide businesses with more intelligent, flexible, and efficient automation solutions, ensuring they remain adaptable to the evolving demands of the logistics industry.

Final Verdict: Which One is Better for Your Business - Knapp or Locus Robotics?

Choosing between Knapp and Locus Robotics depends on your business's specific needs and objectives:

- Knapp: Ideal for large-scale operations requiring full automation and capable of making significant upfront investments. Best suited for businesses aiming for comprehensive automation to achieve long-term cost savings and high efficiency.

- Locus Robotics: Perfect for businesses seeking to enhance productivity through collaborative robots without fully automating their warehouses. The subscription-based model and lower initial costs make it an attractive option for businesses of various sizes.

Ultimately, both solutions offer substantial benefits in terms of warehouse productivity and operational efficiency. Assessing your business's warehousing volume, budget, and long-term automation goals will guide you in selecting the solution that best aligns with your operational strategy.