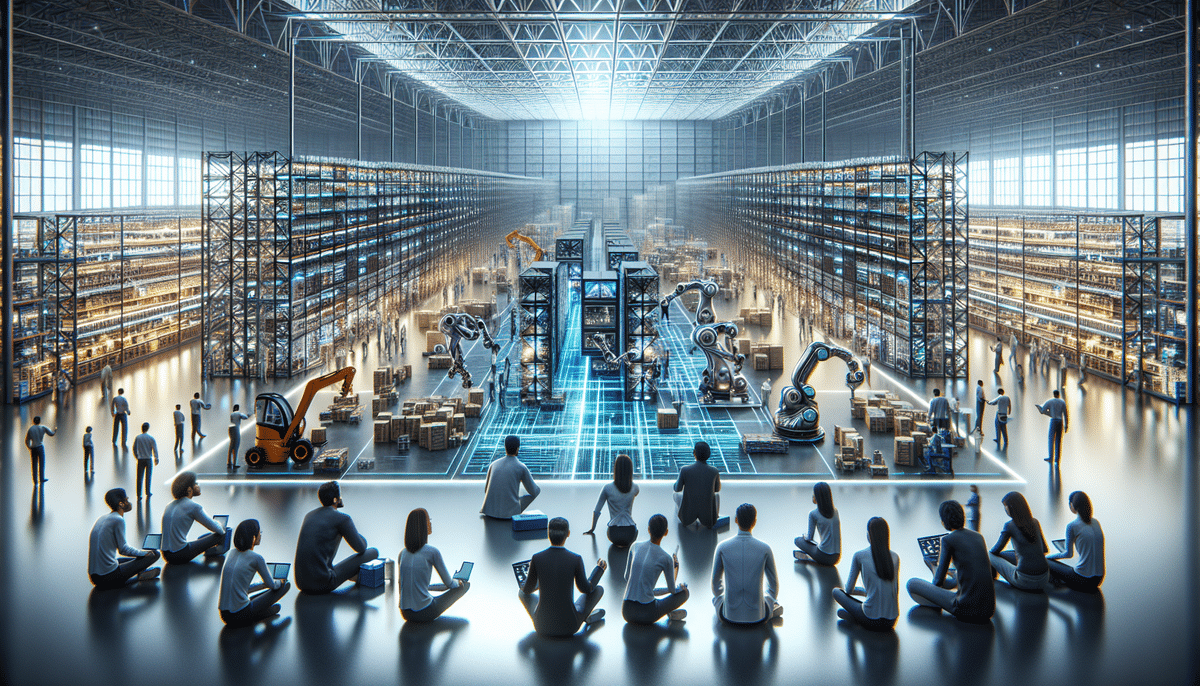

The History of Knapp and Swisslog: A Comprehensive Overview

Warehouse automation has transformed supply chain management, with Knapp and Swisslog emerging as two of the leading providers in this domain. Founded in 1952, Knapp is an Austrian company specializing in automation technology and software solutions for logistics and supply chain management. With operations in over 35 countries, Knapp serves diverse sectors including e-commerce, retail, and healthcare.

Swisslog, established in 1900 in Switzerland, focuses on robotic and automation solutions tailored for warehouses. Known for its precision and reliability, Swisslog serves industries such as healthcare, automotive, and e-commerce. In 2014, Swisslog was acquired by KUKA, a global leader in robotics and automation, further enhancing its technological capabilities.

Since the acquisition, Swisslog has expanded its portfolio, particularly in the healthcare sector, developing innovative solutions like automated medication dispensing systems and robotic storage and retrieval systems. These advancements have significantly improved patient safety and reduced medication errors in hospitals.

Knapp has also been a pioneer in logistics innovation, offering solutions such as automated storage and retrieval systems, shuttle systems, and goods-to-person systems. These technologies have enabled e-commerce businesses to enhance efficiency and expedite order fulfillment, thereby increasing customer satisfaction.

Understanding the Key Differences Between Knapp and Swisslog

While both Knapp and Swisslog provide robust warehouse automation systems, their approaches and technological implementations differ significantly.

Modularity vs. Integration

Knapp emphasizes a modular system design, allowing for easy customization and rapid reconfiguration to meet changing warehouse needs. This modularity provides flexibility, making it suitable for businesses that require adaptable solutions.

In contrast, Swisslog adopts a more integrated approach, resulting in highly efficient but complex systems. This integration is ideal for large-scale operations that demand precision and reliability.

Target Markets

Knapp caters primarily to small and medium-sized warehouses, offering user-friendly interfaces and ease of use. On the other hand, Swisslog targets larger, more complex operations that necessitate specialized training and expertise to operate effectively.

Pros and Cons of Knapp vs Swisslog for Your Business Needs

Selecting the right warehouse automation system requires careful consideration of the strengths and limitations of each provider.

Pros of Using Knapp:

- High flexibility and modularity

- Quick and easy system reconfiguration

- Seamless integration with existing warehouse infrastructure

- Faster implementation times

Cons of Using Knapp:

- May not handle highly complex, high-volume operations effectively

- Potential need for additional integrations with other systems

- Less precision compared to Swisslog’s systems

Pros of Using Swisslog:

- Highly efficient and accurate automation

- Strong integration capabilities with other systems

- Ideal for complex and high-volume operations

Cons of Using Swisslog:

- Lower flexibility and modularity compared to Knapp

- Longer implementation times

- Higher initial costs

Ultimately, the decision between Knapp and Swisslog hinges on your specific business needs, including the size of your operation, complexity of processes, and budget constraints. Consulting with industry experts can further aid in making an informed choice.

Knapp vs Swisslog: Industry-Specific Suitability

The optimal choice between Knapp and Swisslog depends largely on the industry you operate in and the specific requirements of your business.

E-Commerce

For e-commerce businesses that demand rapid order fulfillment and flexibility, Knapp offers modular systems that can quickly adapt to varying order sizes and product types. According to a Forbes technology report, such flexibility is crucial for maintaining high customer satisfaction levels.

Healthcare

Swisslog excels in the healthcare sector with its precise and reliable automation solutions. Automated medication dispensing and robotic storage systems help hospitals minimize errors and enhance patient safety, aligning with industry standards for healthcare management.

Automotive

In the automotive industry, where precision and high-volume operations are paramount, Swisslog provides robust solutions that ensure efficient and accurate inventory management, contributing to streamlined manufacturing and distribution processes.

Comparative Features and Functionalities of Knapp and Swisslog

Both Knapp and Swisslog offer a suite of features designed to enhance warehouse automation, though their focuses differ.

Knapp’s System Features:

- Modular design for easy customization and reconfiguration

- Flexible software solutions enabling seamless system integration

- Intelligent control systems that maximize efficiency and reduce errors

- Advanced storage and retrieval systems

Swisslog’s System Features:

- Highly efficient automation systems boosting productivity and accuracy

- Robotic solutions that enhance operational efficiency and lower costs

- Smart software leveraging data analytics and machine learning for optimal performance

- Customizable solutions that integrate with existing infrastructure

While Knapp’s modularity offers flexibility, Swisslog’s focus on robotics and smart software provides a high level of operational efficiency. The choice between the two should be based on whether your priority is flexibility or efficiency.

Cost Comparison: Knapp vs Swisslog – Which Offers Better Value?

The cost of implementing warehouse automation systems varies based on several factors, including the size and complexity of your operations.

Initial and Ongoing Costs

Swisslog systems tend to be more expensive initially due to their advanced precision and efficiency capabilities. However, for high-volume operations, the long-term benefits may outweigh the higher upfront costs. A study by McKinsey & Company suggests that the ROI for precision-focused systems like Swisslog’s can be realized within 3-5 years depending on usage.

Knapp, with its modular and flexible approach, offers a lower initial investment. While maintenance and potential upgrades may incur additional costs over time, the ability to easily reconfigure the system can lead to cost savings by adapting to changing business needs without significant capital expenditure.

Customization and Flexibility Costs

The high level of customization offered by Swisslog can increase implementation costs, whereas Knapp’s standardized yet flexible solutions may allow for cost-effective adjustments as your business grows.

Ultimately, the best value depends on balancing the initial investment with the long-term operational efficiencies and the specific needs of your warehouse operations.

Customer Reviews and Ratings: Insights from Users of Knapp and Swisslog

Feedback from users indicates strong satisfaction with both Knapp and Swisslog, though each has its unique strengths.

Positive Feedback for Knapp:

- Appreciation for the system's flexibility and modularity

- Ease of integration with existing warehouse infrastructure

- Efficient implementation and quick setup times

Positive Feedback for Swisslog:

- High levels of precision and reliability in operations

- Effectiveness in managing complex and high-volume tasks

- Strong performance of robotic solutions and smart software

Common Concerns:

- Some users report longer wait times for technical support from both companies

- Difficulty in resolving issues promptly

Despite these concerns, users generally recommend Knapp and Swisslog for their innovative and effective automation solutions, highlighting the significant impact on operational efficiency and accuracy.

The Future of Warehouse Automation: The Role of Knapp and Swisslog

As warehouse automation continues to evolve, both Knapp and Swisslog are poised to lead the industry through innovative technologies and strategic advancements.

Integration of Robotics and AI

The adoption of robotics, artificial intelligence (AI), and machine learning will drive the next wave of warehouse automation. Swisslog is at the forefront with its intelligent systems that leverage data analytics to optimize warehouse operations in real-time. These technologies enable predictive maintenance, demand forecasting, and adaptive workflow management, enhancing overall efficiency.

Flexibility and Scalability

Knapp’s modular systems are well-suited to meet the increasing demand for flexibility in warehouse operations. As e-commerce continues to grow, warehouses must adapt to a diverse range of products and fluctuating order volumes. Knapp’s ability to quickly reconfigure its systems makes it an ideal partner for businesses aiming to scale and diversify their offerings.

Sustainability and Efficiency

Environmental sustainability is becoming a key focus in warehouse operations. Both Knapp and Swisslog are developing energy-efficient solutions that reduce operational costs and minimize environmental impact. Innovations such as automated lighting, energy-efficient robotics, and optimized logistics workflows contribute to greener warehouse practices.

According to the World Economic Forum, the integration of sustainable practices in warehouse automation will become increasingly important, and companies like Knapp and Swisslog are well-positioned to lead in this area.

Choosing the Right Warehouse Automation System: Factors to Consider

Deciding between Knapp and Swisslog involves evaluating several critical factors to ensure the chosen system aligns with your business objectives.

Operational Size and Complexity

Assess the scale and complexity of your warehouse operations. Swisslog is better suited for large, intricate operations requiring high precision, while Knapp offers flexibility for smaller to medium-sized warehouses.

Budget and Cost Constraints

Consider both the initial investment and long-term operational costs. Analyze the ROI based on your specific operational needs and expected efficiency gains.

Customization and Flexibility

Determine the level of customization required. Knapp provides highly customizable solutions, whereas Swisslog offers more standardized systems with some flexibility.

Existing Infrastructure

Evaluate how well the automation system will integrate with your current warehouse infrastructure and systems. Seamless integration can reduce implementation time and costs.

Future Expansion Plans

Consider your long-term business goals and potential for expansion. Choose a system that can scale and adapt to future growth and changing business needs.

Support and Maintenance

Evaluate the support and maintenance services offered by each provider. Reliable customer service and quick response times are crucial for minimizing downtime and ensuring smooth operations.

By carefully considering these factors, you can make an informed decision that best suits your warehouse automation needs.

Conclusion

Both Knapp and Swisslog are exemplary providers of warehouse automation systems, each with distinct advantages. Knapp’s strength lies in its flexible and modular solutions, making it ideal for businesses that require adaptability and quick reconfiguration. On the other hand, Swisslog offers highly precise and efficient systems, perfect for large-scale operations that demand reliability and accuracy.

Ultimately, the best choice depends on your specific business requirements, including the size and complexity of your operations, budget constraints, and future growth plans. By evaluating these factors and leveraging the strengths of each provider, you can enhance your warehouse operations, leading to increased efficiency and customer satisfaction.