Learn the Top Strategies for Enterprise Warehousing

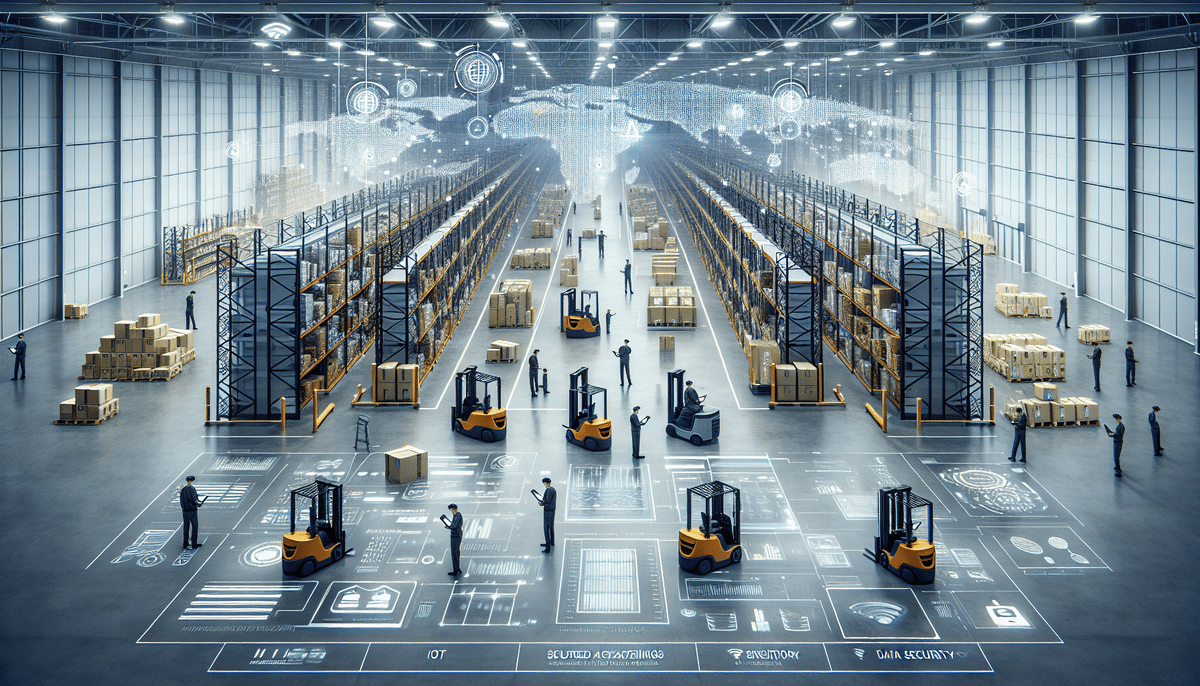

In today's fast-paced business landscape, enterprise warehousing has become a pivotal element in the supply chain management strategies of large-scale organizations. Effective enterprise warehousing involves the storage and handling of substantial volumes of goods and materials, meticulous inventory tracking, and the optimization of various processes to enhance overall operational efficiency. This article delves into the fundamentals of enterprise warehousing, its benefits for businesses, common challenges, criteria for selecting the right warehouse solution, top strategies for optimizing warehouse operations, the role of automation, ensuring data security, improving supply chain management, integrating IoT and Big Data Analytics, and exploring the future of enterprise warehousing with emerging trends and technologies.

Understanding the Basics of Enterprise Warehousing

Enterprise warehousing is a centralized approach to storing and managing goods efficiently in a structured environment. This can be either company-owned or outsourced to third-party logistics providers (3PLs). Unlike individual product storage, enterprise warehousing consolidates multiple goods, which significantly reduces transportation, staffing, and handling costs. According to a 2023 Global Warehouse Management Report, companies leveraging centralized warehousing reported a 15% reduction in operational costs on average.

A critical advantage of enterprise warehousing is the implementation of advanced inventory management systems. These systems utilize real-time data to monitor inventory levels, track product movements, and proactively identify potential issues. This data-driven approach enables companies to optimize inventory levels, minimize waste, and boost overall efficiency. Additionally, enterprise warehousing offers value-added services such as kitting, labeling, and packaging, which help businesses cater to specific customer requirements.

Benefits of Enterprise Warehousing for Businesses

The advantages of enterprise warehousing are multifaceted. Firstly, it ensures the secure and safe storage of goods, which is fundamental for smooth business operations. Secondly, by storing goods in bulk, businesses can significantly reduce transportation and handling costs, delivering products directly to customers as needed. According to the Supply Chain Digital, companies utilizing enterprise warehousing see an average of 20% improvement in inventory turnover rates.

Moreover, enterprise warehousing enhances inventory management, reducing stock wastage and increasing revenue. It also improves operational efficiency by shortening the lead time between production and delivery. The scalability of enterprise warehouses allows businesses to adjust their storage capacity based on demand fluctuations, optimizing resource allocation and minimizing unnecessary expenses. Additionally, faster delivery times enabled by enterprise warehousing provide a competitive edge in today’s market, where customers expect swift and reliable service.

Common Challenges Faced in Enterprise Warehousing

Despite its benefits, enterprise warehousing presents several challenges. Space constraints, effective inventory management, order fulfillment delays, staffing costs, data management, security concerns, and supply chain disruptions are common issues that can adversely affect business operations. These challenges can lead to revenue loss, decreased productivity, and compromised customer satisfaction, making it essential for businesses to implement effective strategies and solutions.

A significant challenge is the lack of real-time visibility into inventory levels, which can result in overstocking or understocking products, leading to increased costs and lost sales. Implementing robust inventory management software that provides real-time data can mitigate this issue by enabling better decision-making and optimal inventory levels.

Another prevalent challenge is the growing demand for faster and more efficient order fulfillment, especially with the surge in e-commerce. To address this, businesses are turning to automated order fulfillment systems, such as robotics and conveyor systems, to enhance efficiency and reduce fulfillment times. According to Forbes, automation can reduce order processing times by up to 30%.

How to Choose the Right Enterprise Warehouse Solution?

Selecting the appropriate enterprise warehouse solution is crucial for optimizing supply chain management. The ideal solution should align with your specific business needs, including inventory requirements, order volumes, security protocols, and other relevant factors. Key considerations when choosing a solution include scalability, cost-effectiveness, technology integrations, and data analytics capabilities. Conducting a comprehensive analysis of your warehouse’s specific needs can help identify the most suitable solution that enhances efficiency, reduces costs, and boosts productivity.

Additionally, evaluating the level of support and training provided by the vendor is essential. A reliable enterprise warehouse solution should offer comprehensive training and support to ensure that your team can effectively utilize the system. Ongoing vendor support is also important for troubleshooting any issues that may arise. Assessing the vendor’s reputation and industry track record can provide insights into their expertise and commitment to customer satisfaction.

Top Strategies for Optimizing Your Enterprise Warehouse Operations

Optimizing enterprise warehousing operations can be achieved through several key strategies. These include regular inventory forecasting, streamlined order processing and fulfillment, optimized warehouse layout, investment in automation and robotic solutions, routine maintenance of machinery and equipment, enhanced employee training, and the implementation of data analytics tools to monitor and analyze operational metrics. These strategies collectively improve overall efficiency, reduce costs, and enhance the customer experience.

Implementing a real-time location system (RTLS) is an additional strategy for optimizing warehouse operations. RTLS utilizes sensors and tags to provide real-time data on the location and movement of items within the warehouse, reducing the time and effort required for manual inventory checks and enhancing inventory accuracy.

Establishing a culture of continuous improvement is another critical strategy. This involves regularly reviewing and analyzing operational processes, identifying areas for enhancement, and implementing changes to optimize efficiency and reduce waste. Fostering such a culture ensures that warehouse operations remain competitive and adaptable to changing market demands.

Implementing Automation in Your Enterprise Warehouse: Benefits and Best Practices

Automation plays a pivotal role in optimizing enterprise warehouse operations by minimizing manual intervention, enhancing accuracy, and accelerating processes. The adoption of automated systems like conveyor belts, robotic arms, and autonomous forklifts enables organizations to achieve higher levels of employee productivity. Best practices for implementing automation include conducting a thorough analysis of the warehouse environment, selecting technology that aligns with specific business needs, integrating automation with existing ERP systems, and investing in regular maintenance and upgrades.

One notable benefit of automation is the reduction of labor costs. By automating repetitive and time-consuming tasks, businesses can decrease the number of employees required to operate the warehouse, leading to substantial long-term savings. Additionally, automation enhances warehouse safety by reducing the risk of accidents caused by human error. It is important to view automation not as a replacement for human workers but as a means to augment their capabilities and improve overall efficiency. According to a McKinsey study, warehouses that have implemented automation have seen a 25% increase in operational efficiency.

Ensuring Data Security in Your Enterprise Warehouse: Tips and Techniques

Data security is paramount for any enterprise, and warehouse operations are no exception. Warehouses handle sensitive information, including inventory data, employee details, and customer information, making it critical to adopt robust security protocols. Key tips for ensuring data security include implementing access control systems, conducting regular audits, investing in cybersecurity solutions, providing ongoing employee training on data security, and developing a comprehensive disaster recovery plan.

Additionally, regularly updating and patching software and hardware systems is essential for maintaining data security. Outdated systems are more vulnerable to cyberattacks, which can compromise sensitive data. Staying current with the latest security patches and updates ensures that systems are protected against potential threats. Regularly reviewing and updating security protocols helps prevent data breaches and safeguards the business from financial and reputational harm. For more insights on data security best practices, refer to the ISO 27001 standard.

How to Improve Your Supply Chain Management with Enterprise Warehousing?

Enterprise warehousing is integral to enhancing supply chain management. Improving supply chain management through enterprise warehousing involves a thorough analysis of various operations, identifying potential bottlenecks, deploying appropriate technology solutions, enhancing communication among stakeholders, implementing data analytics tools, and investing in regular employee training. These measures enable organizations to achieve faster turnaround times, improve order fulfillment, reduce costs, and deliver a superior customer experience.

One of the primary benefits of enterprise warehousing is optimized inventory management. Utilizing advanced inventory management tools allows organizations to track inventory levels in real-time, identify slow-moving items, and make informed decisions regarding reordering. This approach reduces inventory carrying costs and prevents stockouts, which can result in lost sales and dissatisfied customers.

Furthermore, enterprise warehousing enhances transportation management. Integrating transportation management systems (TMS) with warehouse management systems (WMS) enables organizations to optimize transportation routes, reduce transportation costs, and improve delivery times. According to the PwC Supply Chain Report, integrated TMS and WMS solutions can lead to a 10-15% reduction in transportation costs.

Integrating IoT and Big Data Analytics to Enhance Your Enterprise Warehouse Capabilities

The integration of Internet of Things (IoT) and Big Data Analytics significantly enhances the capabilities of enterprise warehouse operations by providing real-time visibility into various processes. IoT sensors can monitor inventory levels, track equipment performance, and ensure employee safety. Concurrently, Big Data Analytics can track performance metrics, identify inefficiencies, and offer predictive maintenance alerts. These technologies collectively improve operational efficiency, reduce costs, and facilitate better warehouse management.

Moreover, integrating IoT and Big Data Analytics optimizes supply chain management by analyzing data from IoT sensors to gain insights into goods movement and identify bottlenecks. This information can be leveraged to streamline the flow of goods, reduce lead times, and enhance customer satisfaction. Big Data Analytics also enables the identification of trends and patterns in customer demand, aiding in more accurate inventory management and strategic product placement.

According to a Gartner report, warehouses that integrate IoT and Big Data Analytics see up to a 30% improvement in operational efficiency.

Future of Enterprise Warehousing: Emerging Trends and Technologies to Watch Out For

The future of enterprise warehousing is poised for transformative changes driven by emerging trends and technologies. These include the use of drones for inventory management, implementation of artificial intelligence (AI) and machine learning (ML) algorithms for predictive analytics, adoption of augmented reality (AR) for employee training, and the integration of blockchain technology for end-to-end supply chain visibility. These advancements are set to revolutionize enterprise warehousing, providing organizations with a competitive advantage.

Drones are increasingly being used for inventory tracking and auditing, significantly reducing the time and effort required for manual checks. AI and ML algorithms enable predictive analytics, allowing warehouses to anticipate demand fluctuations and optimize inventory accordingly. AR technology enhances employee training by providing immersive and interactive learning experiences, improving skill acquisition and operational efficiency. Blockchain technology offers unparalleled transparency and traceability in the supply chain, ensuring data integrity and reducing the risk of fraud.

Additionally, the adoption of sustainable practices and green warehousing is becoming a priority, with technologies aimed at reducing energy consumption and minimizing environmental impact. According to a Forrester report, sustainable warehousing practices can reduce operational costs by up to 20% while enhancing corporate social responsibility.

Conclusion

Enterprise warehousing offers numerous benefits to businesses, including enhanced operational efficiency, cost-effectiveness, and improved customer experiences. However, it also presents several challenges that necessitate effective strategies and solutions. By implementing the right technology solutions, optimizing warehouse operations, ensuring data security, and staying abreast of emerging trends and technologies, organizations can establish a robust, efficient, and future-ready enterprise warehousing system. Embracing these strategies will not only streamline supply chain operations but also position businesses for long-term success in an increasingly competitive market.