Locus Robotics vs Dematic

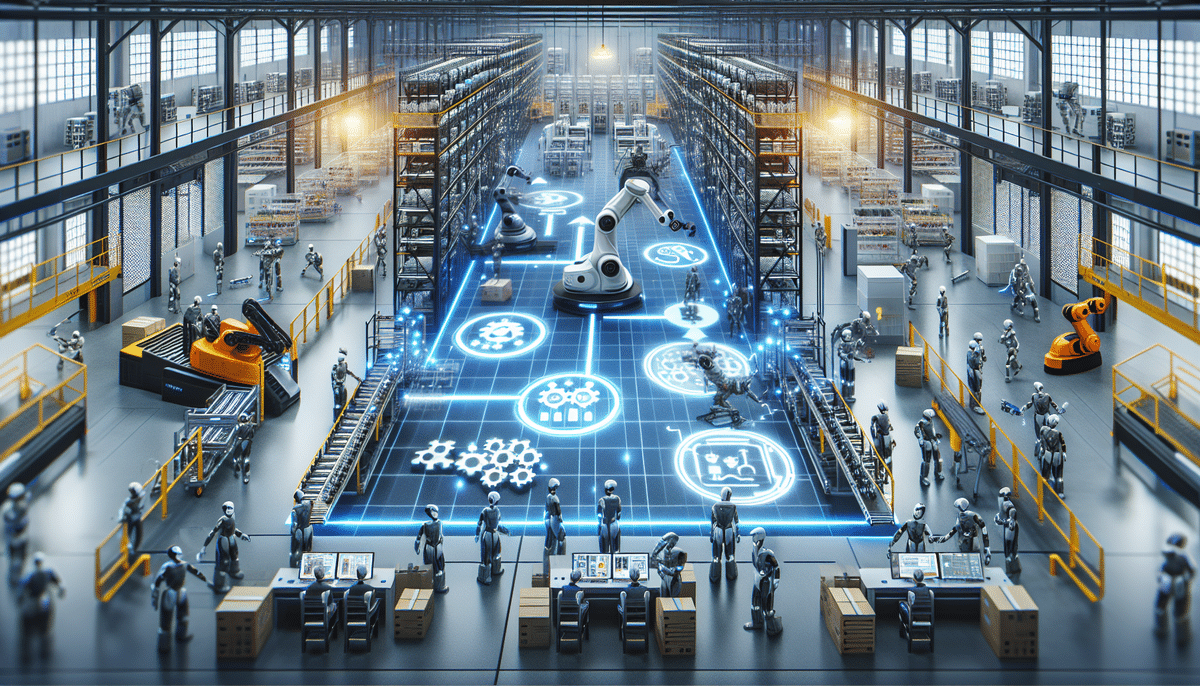

Robotic technology is revolutionizing warehouse operations, and Locus Robotics and Dematic are two of the leading names in the industry. This article provides an in-depth comparison of both companies, examining their history, technology, customer feedback, and future prospects to help you make an informed decision.

Introduction to Locus Robotics and Dematic

Locus Robotics is a Massachusetts-based company founded in 2014, specializing in collaborative robots designed to work alongside human workers in warehouses. Their robots are utilized by major companies such as DHL, GEODIS, and Radial. Dematic, headquartered in Grand Rapids, Michigan, is a global supplier of integrated automated technology, software, and services. With operations in over 25 countries, Dematic serves diverse industries including retail, e-commerce, and manufacturing.

Together, Locus Robotics and Dematic have the potential to deliver comprehensive warehouse automation solutions. By leveraging Locus Robotics' innovative robotic technology and Dematic's expertise in automation and software, warehouses can achieve optimized operations, increased productivity, and reduced costs. This synergy is pivotal in addressing the evolving demands of modern logistics.

History of Locus Robotics and Dematic: A Brief Overview

Locus Robotics was founded by Bruce Welty and Mike Johnson, who leveraged their backgrounds in logistics to create advanced warehouse robotics solutions. The company has secured over $105 million in funding and was acquired by the global logistics firm Körber in 2020. Dematic boasts a rich history dating back to the 1930s, initially known as Rapistan. In 2006, it merged with several companies to become Dematic, and in 2016, it was acquired by KION Group, a leading provider of forklifts and warehouse equipment.

Since its acquisition by Körber, Locus Robotics has expanded its operations and partnerships. In 2021, they partnered with DHL Supply Chain to deploy robots across North American warehouses, enhancing efficiency, productivity, and safety. Locus Robotics has also introduced new robots tailored for specific tasks like picking and packing, positioning themselves for continued growth and innovation in the logistics sector.

Similarities and Differences Between Locus Robotics and Dematic

Both Locus Robotics and Dematic offer robotic solutions for warehouses, but they differ in their approaches and product offerings:

- Locus Robotics focuses on collaborative robots that assist human workers, enhancing flexibility and adaptability in various tasks.

- Dematic provides a broader range of solutions, including conveyor systems and automated storage and retrieval systems, catering to more specialized warehouse needs.

Despite these differences, both companies leverage advanced technology to optimize warehouse operations, utilizing cutting-edge software and hardware to improve accuracy, speed, and safety. They also offer customizable solutions tailored to the specific requirements of their clients.

However, Locus Robotics emphasizes flexibility and real-time adaptability, while Dematic offers specialized solutions focused on specific areas such as material handling and order fulfillment. The choice between the two depends on the unique needs and priorities of each warehouse operation.

The Technology Behind Locus Robotics and Dematic

Locus Robotics utilizes its Adaptive Fulfillment System (AFS), which employs artificial intelligence and machine learning to optimize picking routes and enhance warehouse efficiency. Their LocusBots collaborate with human workers, equipped with sensors and cameras for navigation and item location, ensuring accurate picking and packing.

Dematic offers a variety of technologies, including the Multishuttle system for storing and retrieving items and Automated Guided Vehicles (AGVs) that navigate warehouses using sensors. Additionally, Dematic provides the Warehouse Execution System (WES), which integrates with existing warehouse management systems to offer real-time visibility into inventory, order status, and equipment performance, enabling data-driven decision-making.

Both companies provide robust software solutions to help warehouse managers optimize operations, enhance efficiency, and reduce costs.

Key Technological Features

- Locus Robotics

- Adaptive Fulfillment System (AFS): Uses AI to optimize operations.

- LocusBots: Collaborative robots with advanced navigation.

- Dematic

- Multishuttle System: Efficient storage and retrieval.

- Automated Guided Vehicles (AGVs): Seamless navigation and task execution.

- Warehouse Execution System (WES): Comprehensive real-time data integration.

Advantages of Using Locus Robotics Over Dematic

- Collaborative Robots: Locus Robotics' robots work alongside human workers, adapting to workflow changes and enhancing real-time efficiency.

- Adaptive Fulfillment System: The AFS technology significantly reduces order fulfillment time, leading to faster shipping and increased customer satisfaction.

- Flexibility and Scalability: Locus Robotics' systems can be easily integrated and reconfigured to meet changing demands and warehouse layouts, allowing businesses to scale without extensive overhauls.

Advantages of Using Dematic Over Locus Robotics

- Comprehensive Solutions: Dematic offers a wider range of warehouse automation solutions, enabling tailored approaches to meet specific client needs.

- Industry Expertise: With decades of experience, Dematic provides invaluable expertise and handles large-scale, complex warehouse operations effectively.

- System Integration: Dematic's solutions seamlessly integrate with various warehouse management systems, ensuring smooth transitions and enhanced data management.

Customer Reviews Comparison

Customer feedback for both Locus Robotics and Dematic is largely positive. Clients of Locus Robotics commend the collaborative nature of their robots and the efficiency improvements they bring. Dematic's clients appreciate the customized solutions and reliability of their services. However, some clients have reported challenges with installation and maintenance for both companies.

Locus Robotics excels in customer service, with many clients highlighting quick responses and excellent support during implementation. Conversely, Dematic is praised for handling large-scale projects and their deep expertise in complex warehouse operations.

In terms of pricing, both companies offer competitive rates. Locus Robotics is noted for its transparent pricing and willingness to work within client budgets, while Dematic is perceived as more expensive but justifies the cost through high-quality products and services.

The Impact of COVID-19 on Locus Robotics and Dematic

The COVID-19 pandemic significantly affected the logistics industry, boosting demand for warehouse automation as online shopping surged. Both Locus Robotics and Dematic experienced increased demand for their solutions. Locus Robotics implemented safety measures such as social distancing and enhanced cleaning protocols to protect their workforce and clients.

Despite rising demand, both companies faced supply chain disruptions. Locus Robotics had to adjust production schedules and source materials from alternative suppliers, while Dematic dealt with delays in receiving essential components, resulting in longer lead times for customers.

Nevertheless, the pandemic also spurred innovation. Locus Robotics developed new software features to enhance robot efficiency, and Dematic expanded its offerings to include contactless delivery options. These adaptations have positioned both companies for continued leadership in the evolving logistics landscape.

Case Studies: Successful Implementations

Locus Robotics has partnered with DHL to enhance efficiency in their e-commerce fulfillment centers, demonstrating significant improvements in order processing times and accuracy. Dematic has worked with companies like Coca-Cola to optimize warehouse operations, showcasing their ability to tailor solutions to diverse industry needs.

These case studies illustrate how both Locus Robotics and Dematic can effectively customize their solutions to meet the unique requirements of various clients, highlighting their versatility and expertise in warehouse automation.

Challenges Faced by Locus Robotics and Dematic

Both Locus Robotics and Dematic operate in a highly competitive market, contending with startups and established giants like Amazon. The high cost of implementing robotic solutions also poses a barrier for some businesses.

Additionally, maintaining technological advancements and keeping up with rapidly changing industry standards are ongoing challenges. Both companies must continuously innovate to stay ahead of competitors and meet the evolving needs of the logistics sector.

Future Prospects for Locus Robotics and Dematic

The future appears promising for both Locus Robotics and Dematic. As the logistics industry continues to grow and evolve, the demand for efficient and innovative warehouse automation solutions will increase. Locus Robotics' acquisition by Körber provides a strong foundation for continued growth, while Dematic's extensive industry expertise ensures they remain competitive.

Both companies are expected to push the boundaries of warehouse automation, incorporating advancements in artificial intelligence, machine learning, and robotics to deliver even more sophisticated and effective solutions.

Conclusion: Which Company is the Best Fit for Your Business?

Choosing between Locus Robotics and Dematic depends on your business's specific needs. If you require a collaborative solution that enhances human worker productivity, Locus Robotics may be the ideal choice. However, if you need a comprehensive, customizable solution tailored to your unique operational requirements, Dematic might be the better fit. Both companies offer innovative and reliable warehouse automation solutions, ensuring that whichever you choose, your business will benefit from cutting-edge technology and industry expertise.