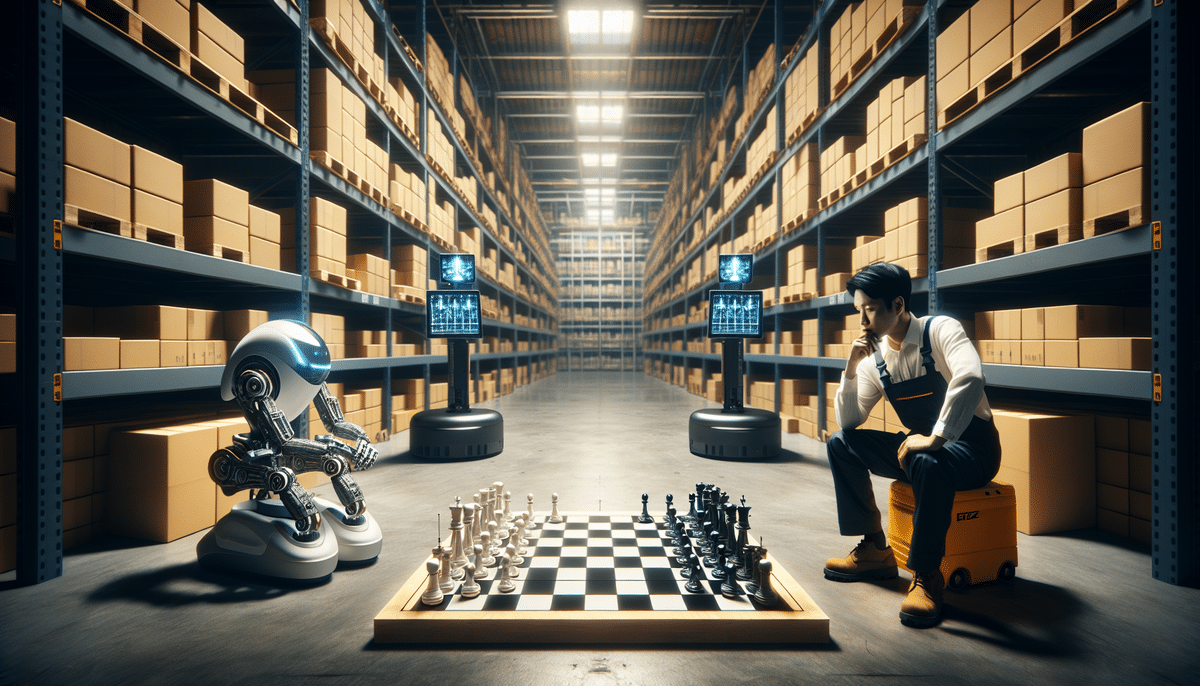

Locus Robotics vs Kiva Systems (Amazon Robotics)

As the demand for fast and efficient delivery of products continues to soar, warehouse automation has become increasingly important for businesses looking to streamline their operations. Two of the most popular systems available in the market today are Locus Robotics and Kiva Systems (now Amazon Robotics). This article provides an in-depth comparison of these two warehouse automation systems to help business owners make an informed decision when choosing which system to implement.

Overview of Locus Robotics and Kiva Systems

Locus Robotics

Locus Robotics is an innovative warehouse automation system that utilizes collaborative robots to enhance warehouse efficiency and productivity. The system employs a network of robots that work alongside human workers to pick and move products throughout a warehouse. The robots are designed to be highly agile and flexible, allowing them to navigate narrow aisles and tight spaces efficiently.

Kiva Systems (Amazon Robotics)

Similarly, Kiva Systems (acquired by Amazon and rebranded as Amazon Robotics) is a warehouse automation technology that leverages mobile robots to automate distribution centers and warehouses. The system uses autonomous mobile robots that swiftly transport products from one location to another. These robots are engineered to navigate around obstacles and travel at high speeds, facilitating fast and efficient order fulfillment.

Revolutionizing Warehouse Automation

Efficiency and Cost Savings

Locus Robotics and Kiva Systems are both revolutionizing the way products are moved within warehouses, making order fulfillment faster, cheaper, and more accurate. These systems automate many of the manual tasks associated with warehouse operations, freeing up human workers to engage in higher-level tasks that require reasoning, creativity, and decision-making.

According to a Forbes report, automated systems can reduce operational costs by up to 30% while improving order accuracy.

Inventory Management

Another advantage is optimized inventory management. These systems can track inventory levels in real-time, allowing businesses to make informed decisions about when to reorder products and how much inventory to maintain. This helps in reducing waste and avoiding stockouts, which can lead to lost sales and dissatisfied customers.

Workplace Safety

Furthermore, warehouse automation systems enhance workplace safety by handling heavy lifting and other physically demanding tasks, reducing the strain on human workers and minimizing the risk of musculoskeletal injuries. A safer work environment can lead to higher job satisfaction and lower employee turnover rates.

Comparative Analysis: Locus Robotics vs Kiva Systems

Collaboration vs. Independence

- Collaboration: Locus Robotics' robots are designed to work collaboratively with human workers, enhancing productivity through teamwork. In contrast, Kiva Systems' robots operate independently, managing tasks without direct human collaboration.

Navigation Capabilities

- Agility: Locus Robotics' robots are highly agile and can maneuver through tight spaces, whereas Kiva Systems' robots follow pre-determined paths, which may limit flexibility in certain warehouse layouts.

Inventory Handling

- Advanced Sensors: Locus Robotics' robots are equipped with advanced sensors for item detection and localization, facilitating efficient picking and transportation. Kiva Systems' robots typically rely on barcodes and markers to locate items, which can be less efficient in dynamic environments.

Despite these differences, both systems offer significant benefits, including reduced manual labor, increased efficiency, and cost savings. The choice between them depends on specific business needs, warehouse layout, and operational requirements.

Cost Comparison

Pricing Models

- Locus Robotics: Offers a pay-per-usage pricing model, meaning businesses only pay for the time the robots are actively used. This model can be particularly cost-effective for businesses with variable order volumes or seasonal demand spikes.

- Kiva Systems: Utilizes a traditional pricing model with upfront costs for equipment and licensing fees. While this requires a higher initial investment, it may be more economical in the long run for warehouses with consistent high-volume operations.

Total Cost of Ownership

According to a Robotics Business Review, the total cost of ownership for Kiva Systems can be approximately 20-30% higher initially compared to Locus Robotics but may offer better ROI over time for large-scale operations.

Case Studies: Real-World Implementations

- DHL Supply Chain: Implemented Locus Robotics to optimize their warehouse operations, resulting in a 30% increase in picking productivity and significant reductions in error rates.

- Amazon: Utilizes Kiva Systems extensively in its fulfillment centers, enabling the company to process millions of orders efficiently and maintain rapid delivery times.

These case studies highlight the tangible benefits both systems can provide, including increased efficiency, higher productivity, and improved customer satisfaction.

Future of Warehouse Automation

- Artificial Intelligence Integration: Future iterations may incorporate more advanced AI for improved decision-making and autonomous operations.

- Enhanced Collaboration: Increased focus on seamless human-robot collaboration to further boost productivity and safety.

- Sustainability: Development of more energy-efficient robots to reduce the environmental impact of warehouse operations.

According to a Forbes Technology Council report, the warehouse automation market is projected to grow by 20% annually, driven by advancements in robotics and AI technologies.

Impact on the E-commerce Industry

- Faster Order Fulfillment: Automation allows e-commerce companies to process and ship orders more quickly, meeting the high expectations of today's consumers.

- Increased Accuracy: Reduced errors in order picking and fulfillment lead to higher customer satisfaction and lower return rates.

- Scalability: Automated systems can easily scale to handle fluctuating order volumes, especially during peak shopping seasons.

As a result, e-commerce companies leveraging these automation systems can enhance customer experience, leading to increased revenue and customer loyalty.

Pros and Cons of Locus Robotics vs Kiva Systems

Pros of Locus Robotics

- Collaborative operation with human workers.

- High agility and flexibility in navigating warehouse layouts.

- Pay-per-usage pricing model.

- Real-time data analytics for informed decision-making.

Cons of Locus Robotics

- Requires close collaboration between robots and human workers, which may not suit all business models.

- Potential dependency on continuous human oversight.

Pros of Kiva Systems

- Independent operation allowing for 24/7 warehouse management.

- Proven scalability for large-scale operations.

- Integration with Amazon's extensive e-commerce platform.

Cons of Kiva Systems

- Higher initial investment costs.

- Less flexibility in adapting to changing warehouse layouts.

Ultimately, the decision between Locus Robotics and Kiva Systems should be based on a thorough evaluation of your business's specific needs, operational workflows, and budget constraints.

Overcoming Implementation Challenges

Implementing warehouse automation systems like Locus Robotics and Kiva Systems can present several challenges. Here are some lessons learned to ensure a smoother transition:

- Comprehensive Planning: Carefully plan the warehouse layout to accommodate robots and optimize workflows. This includes designated charging stations, clear pathways, and adequate space for robot movement.

- Employee Training: Provide thorough training for staff to effectively interact with and manage the automated systems. This helps in minimizing resistance and ensuring seamless human-robot collaboration.

- Integration with Existing Systems: Ensure that the automation system integrates well with existing warehouse management software and other operational tools.

- Continuous Monitoring and Optimization: Regularly monitor the performance of the automation system and make necessary adjustments to improve efficiency and address any issues promptly.

According to a Supply Chain 247 article, businesses that invest in proper planning and training experience a higher success rate in automation implementation.

Key Features to Consider

- Speed and Efficiency: Evaluate the robots' operational speed and how efficiently they can handle order fulfillment tasks.

- Flexibility: Assess the system's ability to adapt to different warehouse layouts and handle various product types.

- Safety Features: Ensure that the robots have robust safety mechanisms to prevent accidents and protect human workers.

- Scalability: Consider how easily the system can be scaled to meet changing business demands.

- Pricing Models: Compare the cost structures of both systems to determine which aligns better with your budget.

- Support and Maintenance: Look into the availability of customer support, maintenance services, and system updates.

Choosing a system that aligns with your operational needs and long-term business goals will ensure a successful implementation of warehouse automation.

Expert Opinions on Locus Robotics vs Kiva Systems

Industry experts offer varied perspectives on which warehouse automation system excels. Here are some insights:

- Collaborative Efficiency: Experts who value human-robot collaboration often favor Locus Robotics for its ability to enhance worker productivity and flexibility.

- Scalability and Independence: Those prioritizing scalability and independent robot operation tend to prefer Kiva Systems, especially for large-scale warehouses and 24/7 operations.

- Cost-Effectiveness: Businesses with fluctuating order volumes might lean towards Locus Robotics' pay-per-usage model, while those with steady high-volume operations may find Kiva Systems more cost-effective in the long term.

Ultimately, the choice between Locus Robotics and Kiva Systems depends on a business's specific requirements, operational workflows, and strategic objectives. Consulting with industry experts and conducting pilot programs can provide valuable insights to inform the decision-making process.

Conclusion

In conclusion, Locus Robotics and Kiva Systems are two of the most popular and highly-rated warehouse automation systems available in the market today. These systems offer numerous benefits to businesses, including improved efficiency, accuracy, and customer satisfaction. When deciding which system to implement, business owners should carefully consider their warehouse layout, the types of products handled, budget, and other key factors to determine which system best fits their business needs.