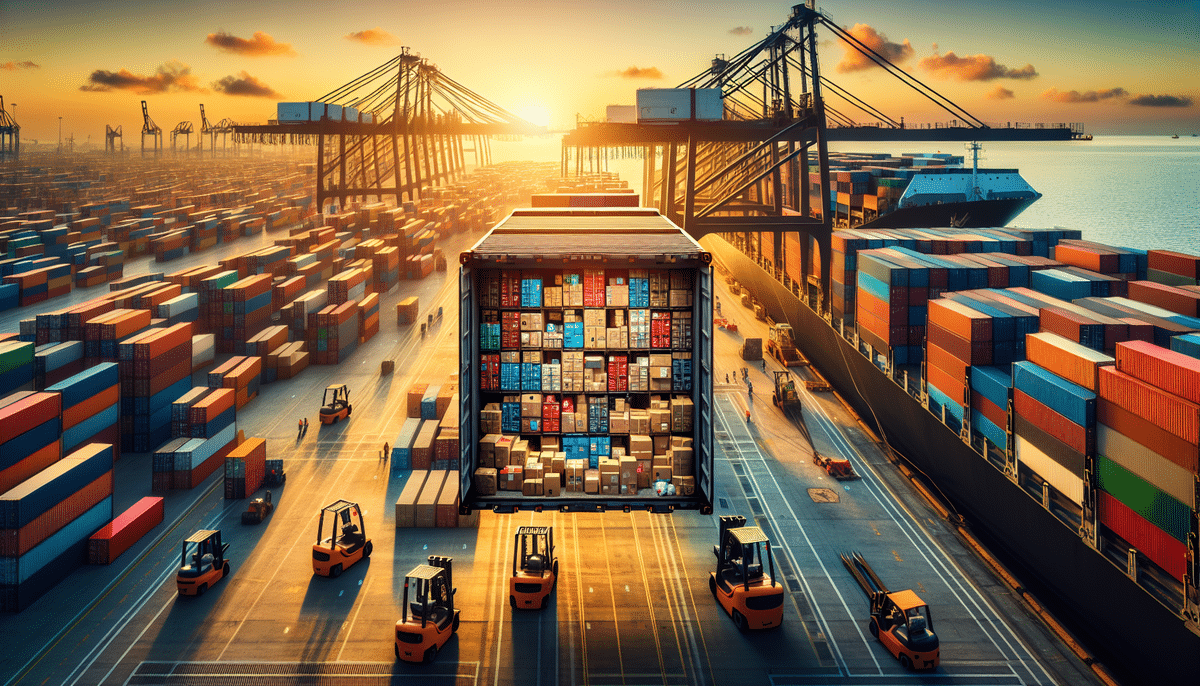

Maximizing Efficiency Through Container Consolidation

Container consolidation is a strategic logistics approach that involves combining multiple shipments into a single container. This method offers numerous advantages, including reduced shipping costs, streamlined supply chain management, and enhanced control over the transportation process. In this article, we delve into the benefits of container consolidation and provide actionable insights on implementing this strategy in your business operations to maximize efficiency and achieve significant cost savings.

Understanding Container Consolidation and Its Benefits

Container consolidation optimizes the shipping process by merging multiple smaller shipments into fewer, fully-loaded containers. For instance, instead of dispatching five half-empty containers from different factories, shipments are combined into fewer full containers. This approach yields several key benefits:

- Reduced Shipping Costs: Consolidating shipments lowers overall transportation expenses by maximizing container space utilization.

- Improved Supply Chain Management: Enhanced coordination leads to more efficient inventory control and reduced lead times.

- Greater Control Over Transportation: Fewer shipments provide better oversight and management of the transportation process.

Successful container consolidation hinges on meticulous planning and execution. By optimizing freight consolidation, businesses can not only cut shipping costs but also lower their carbon footprint and improve delivery times. Additionally, leveraging consolidation allows for negotiating better rates with carriers due to the increased volume of consolidated shipments.

Another significant advantage is the reduced risk of goods damage. Fewer containers mean less movement and shifting within each container, which minimizes the chances of damage, particularly for fragile or high-value items. Moreover, consolidating shipments reduces the number of trucks or ships required, further decreasing the risk of accidents or delays.

The Importance of Container Consolidation in Supply Chain Management

In the realm of supply chain management, especially for businesses engaged in international shipping, container consolidation is pivotal. In today's competitive global marketplace, optimizing supply chain operations is essential for maintaining profitability. Container consolidation provides several benefits:

- Enhanced Visibility and Control: Consolidated shipments offer better tracking and management capabilities.

- Faster and More Accurate Deliveries: Streamlined processes lead to quicker and more reliable delivery times.

- Reduced Risk of Damage or Loss: Fewer handling stages decrease the likelihood of goods being damaged or lost.

By consolidating shipments, businesses can maintain optimal inventory levels, reducing the risk of stock-outs. Standardized containers further enhance delivery accuracy and speed while minimizing the chances of goods being damaged or lost during transit.

Cost reduction is another critical benefit. Consolidating multiple shipments into a single container significantly lowers transportation expenses, including fuel and handling fees. This can translate to up to a 40% reduction in transportation costs, as highlighted in our case studies. Additionally, container consolidation contributes to environmental sustainability by decreasing the number of trips required to transport goods, thereby reducing greenhouse gas emissions.

Container Consolidation vs. Traditional Shipping: Which is More Efficient?

Traditional shipping methods typically involve sending separate containers for each shipment, which can be inefficient and costly. In contrast, container consolidation offers a more efficient alternative by merging multiple shipments into a single container. This not only reduces shipping costs but also enhances supply chain efficiency.

Furthermore, container consolidation allows businesses to better manage inventory levels, leading to cost savings and improved customer satisfaction. By reducing the number of containers shipped, companies can also lower their carbon footprint, contributing to more sustainable business practices.

However, container consolidation may not be suitable for every business. For companies with high volumes of shipments destined for various locations, traditional shipping methods might be more effective in ensuring timely deliveries. Additionally, consolidation requires more detailed planning and coordination among all parties involved in the shipping process.

Despite these challenges, container consolidation remains a viable and advantageous option for many businesses aiming to optimize their shipping operations and reduce costs. By thoroughly evaluating shipping needs and collaborating with experienced logistics providers, companies can determine the best approach for their specific circumstances.

The Role of Technology in Optimizing Container Consolidation

Technology is indispensable in optimizing container consolidation and overall supply chain management. Advanced software solutions enable businesses to track shipments, manage inventory levels, and maximize container utilization effectively. Technologies such as RFID tags and GPS tracking systems enhance the ability to monitor and manage supply chain operations, resulting in improved efficiency and cost savings.

Blockchain technology is increasingly being adopted in container consolidation for its ability to provide a secure and transparent method of tracking and verifying transactions. By utilizing blockchain, businesses ensure that all parties within the supply chain have access to consistent and accurate information, reducing the risk of errors and delays. This technology also enhances traceability and accountability, which is crucial for industries like food and pharmaceuticals where product safety is paramount.

How to Choose the Right Container Size for Your Business

Selecting the appropriate container size is crucial for the success of container consolidation. Key factors to consider include the volume of goods being shipped, the dimensions of the products, and any special handling requirements or constraints that may affect delivery. By carefully evaluating these factors, businesses can choose the optimal container size to enhance their shipping operations.

The mode of transportation also plays a significant role in determining the right container size. Different transportation modes have varying size restrictions and requirements. For example, air shipments may necessitate smaller containers to comply with weight and size limits, while sea shipments can accommodate larger containers to maximize space and reduce costs. It is essential to research and understand the specific size limitations and requirements of your chosen transportation mode before selecting a container size.

Top Strategies for Implementing Container Consolidation in Your Operations

Implementing container consolidation effectively requires strategic planning and execution. Businesses can adopt several strategies to optimize their consolidation efforts:

- Partner with Trusted Carriers and Logistics Providers: Collaborate with reliable partners to ensure smooth and efficient consolidation processes.

- Invest in Advanced Technology and Software: Utilize software solutions that facilitate tracking, inventory management, and container optimization.

- Optimize Inventory Levels: Maintain optimal inventory levels to ensure timely and efficient consolidation of shipments.

- Collaborate with Suppliers and Customers: Work closely with suppliers and customers to synchronize logistics operations and maximize consolidation benefits.

Conducting a comprehensive analysis of your supply chain is another critical strategy. This involves identifying areas where waste can be reduced, processes can be streamlined, and efficiency can be enhanced. By analyzing the supply chain, businesses can pinpoint opportunities for consolidating shipments, reducing transportation costs, and improving delivery times. Additionally, identifying potential risks allows companies to develop contingency plans to mitigate them. A holistic approach to container consolidation can lead to substantial cost savings and improved logistics operations.

Common Challenges with Container Consolidation and How to Overcome Them

While container consolidation offers numerous benefits, it also presents certain challenges. Common issues include managing inventory levels, coordinating shipments with suppliers and customers, and optimizing container utilization. To address these challenges, businesses can implement technologies such as inventory management software and establish clear communication channels with partners and suppliers.

Ensuring the safety and security of transported goods is another challenge. Consolidating multiple shipments into one container can increase the risk of damage or theft during transit. To mitigate these risks, businesses should invest in secure packaging, advanced tracking technologies, and partner with trusted logistics providers known for safe and secure transportation.

Additionally, container consolidation can lead to longer transit times and potential delays, which can be problematic for time-sensitive or perishable goods. To combat this, businesses should work with logistics providers who have robust transportation networks and can offer expedited shipping options when necessary.

Cost Savings through Container Consolidation: Real-life Examples and Case Studies

Container consolidation can result in significant cost savings for businesses. Real-life examples and case studies demonstrate that optimizing shipping operations through consolidation can reduce transportation costs by up to 40% and decrease inventory holding costs by up to 70%. Furthermore, container consolidation can lead to faster delivery times, fewer stock-outs, and enhanced customer satisfaction.

One of the primary benefits of container consolidation is the reduction of carbon emissions. By consolidating shipments, companies can decrease the number of trucks on the road, leading to lower fuel consumption and reduced greenhouse gas emissions. This not only benefits the environment but also enhances a company's reputation among environmentally conscious consumers. For instance, some businesses have reported a 20% reduction in carbon emissions as a result of implementing container consolidation strategies.

For more insights and detailed case studies, visit our Case Studies page.

Best Practices for Managing Inventory Levels with Container Consolidation

Effective inventory management is essential for successful container consolidation. To optimize inventory levels, businesses should adopt the following best practices:

- Utilize Inventory Management Software: Implement software solutions to streamline ordering and stocking processes, ensuring optimal inventory levels.

- Collaborate with Suppliers and Customers: Align supply and demand through close collaboration, facilitating efficient logistics operations.

- Implement a Just-in-Time (JIT) inventory management system: Adopt JIT systems to manage inventory levels effectively, reducing excess stock and minimizing storage costs.

The Future of Container Consolidation: Trends and Predictions

Looking ahead, container consolidation is poised to play an increasingly vital role in global logistics. Emerging trends such as the exponential growth of e-commerce, advancements in automation and artificial intelligence, and a heightened focus on sustainability are expected to drive the demand for container consolidation in the coming years. By embracing these trends, businesses can stay competitive and enhance their logistics operations.

One significant trend is the integration of artificial intelligence and machine learning in logistics software, which can further optimize container consolidation by predicting shipment patterns and enhancing decision-making processes. Additionally, the push towards sustainable business practices will encourage more companies to adopt container consolidation as a means to reduce their environmental impact.

As technology continues to evolve and new innovations emerge, container consolidation is likely to become even more integral to the logistics industry, offering enhanced efficiency, cost savings, and sustainability.

Conclusion: Embracing Container Consolidation for a More Efficient Business Model

Container consolidation provides numerous benefits for businesses, including reduced shipping costs, enhanced supply chain management, and greater control over the transportation process. By adopting container consolidation, businesses can optimize their shipping operations, improve inventory management, and lower their carbon footprint. To maximize these benefits, companies should focus on best practices such as partnering with trusted carriers and logistics providers, investing in advanced technology, and maintaining optimal inventory levels.

It's important to recognize that container consolidation is not a universal solution for all businesses. Carefully evaluating your shipping needs and determining the suitability of container consolidation based on factors like product type, shipment frequency, and delivery destinations is crucial. Additionally, being aware of potential drawbacks, such as longer transit times or the need for additional handling and storage, allows businesses to make informed decisions.

By strategically implementing container consolidation, businesses can achieve a more efficient and cost-effective logistics model, paving the way for sustained growth and competitive advantage.