Maximizing Efficiency with East Coast Warehousing

In today's fast-paced business environment, ensuring operational efficiency is crucial for companies aiming to remain competitive and profitable. Utilizing warehousing facilities on the East Coast of the United States offers a strategic advantage. This article provides an in-depth analysis of East Coast warehousing, discusses the benefits of this prime location, and offers practical tips for businesses looking to optimize their supply chains and streamline warehousing operations for maximum efficiency and profitability.

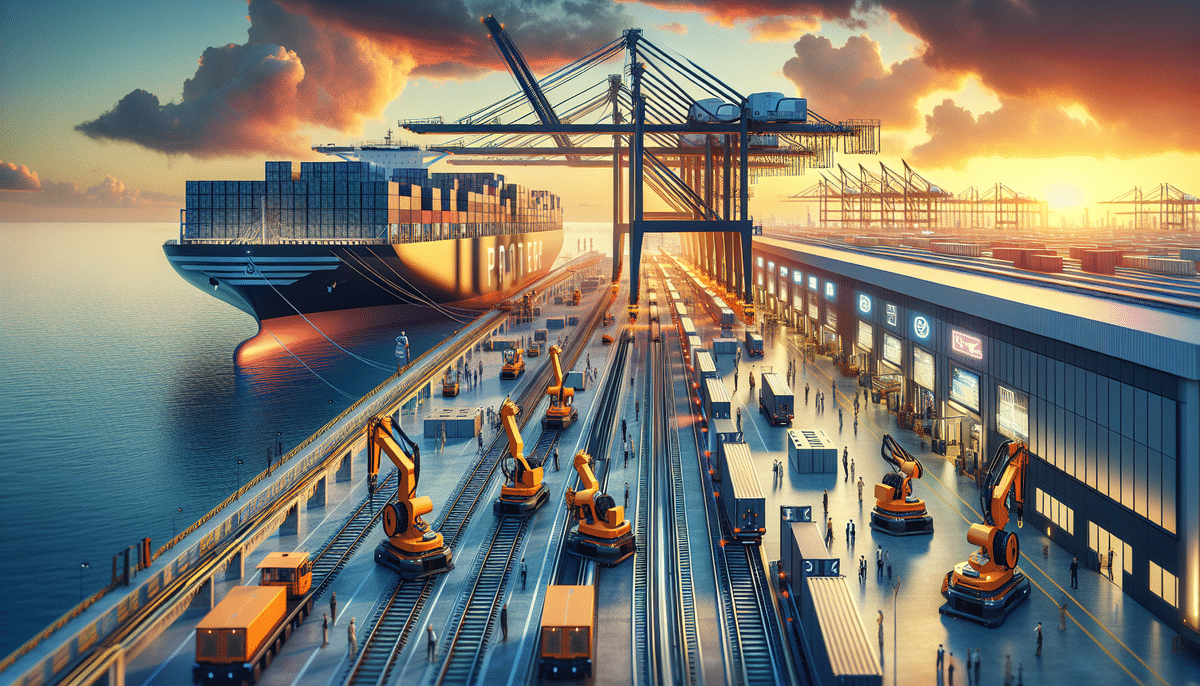

An Overview of East Coast Warehousing

The East Coast of the United States hosts some of the busiest ports globally, including the Port of New York and New Jersey, the Port of Savannah, and the Port of Norfolk. These ports facilitate efficient import and export operations, making the region a prime location for warehousing and distribution. Proximity to major cities like New York, Boston, and Philadelphia, combined with access to major highways and transportation hubs, ensures that East Coast warehouses provide seamless access to both domestic and international markets.

East Coast warehouses also offer a variety of specialized services tailored to different industries. For instance, warehouses specializing in temperature-controlled storage are essential for perishable goods such as food and pharmaceuticals. Additionally, facilities offering secure storage are ideal for high-value items like electronics and jewelry. Value-added services, including packaging, labeling, and order fulfillment, further enhance the efficiency of supply chains, enabling businesses to streamline their operations effectively.

The Benefits of Warehousing on the East Coast

Locating warehousing operations on the East Coast presents several advantages:

- Proximity to Major Markets: Being close to major population centers like New York City and Miami reduces delivery times and shipping costs, enhancing customer satisfaction.

- Robust Infrastructure: The East Coast boasts a well-developed infrastructure with extensive highways, rail lines, and ports, facilitating efficient movement of goods.

- Access to Skilled Labor: The region is home to a highly educated workforce with expertise in logistics and supply chain management, allowing businesses to find qualified employees easily.

- Flexibility and Scalability: A wide range of warehouse sizes and types are available, and many facilities offer customizable services such as pick-and-pack and labeling to meet specific business needs.

According to the 2023 Warehousing Report, businesses on the East Coast have seen a 15% increase in operational efficiency due to strategic warehousing locations.

Factors to Consider When Choosing a Warehousing Location

Selecting the right East Coast location for warehousing operations involves evaluating several factors:

- Proximity to Markets and Transportation Hubs: Ensures quick access to key markets and efficient transportation options.

- Cost of Living and Real Estate: Varies significantly across different states and cities, affecting overall operational costs.

- Workforce Availability: Access to a skilled and experienced labor pool is essential for smooth operations.

- Regulatory Environment: Understanding local regulations and tax structures can impact business costs and compliance requirements.

- Security and Safety: Evaluating crime rates and natural disaster risks is crucial for protecting goods and ensuring employee safety.

Businesses should conduct thorough research and possibly consult with logistics experts to assess these factors effectively. Resources such as the ShipScience Market Insights can provide valuable data for decision-making.

How to Optimize Your Supply Chain with East Coast Warehousing

Optimizing your supply chain involves several strategies:

- Implement Warehouse Management Systems (WMS): Utilizing advanced WMS can monitor inventory levels, streamline shipping and receiving, and reduce errors.

- Effective Inventory Management: Ensuring the right products are in the right place at the right time minimizes waste and increases productivity.

- Adopt Intermodal Transportation: Combining multiple transportation modes, such as rail and trucking, can reduce costs and improve efficiency.

- Transportation Management Systems (TMS): Implementing TMS helps track shipments, manage carrier relationships, and identify cost-saving opportunities.

- Enhance Communication: Maintaining open lines of communication with suppliers and customers helps anticipate demand and manage inventory effectively.

According to the 2023 Supply Chain Optimization Report, businesses that leverage technology in their supply chains have seen a 20% increase in efficiency.

The Role of Technology in Efficient Warehousing Operations

Modern East Coast warehouses leverage cutting-edge technologies to enhance efficiency:

- Automation and Robotics: Automated systems perform tasks such as picking, packing, and palletizing, increasing speed and reducing human error.

- Drones: Used for inventory checks, monitoring stock levels, and delivering small packages within the warehouse, drones enhance accuracy and safety.

- Artificial Intelligence (AI) and Machine Learning: These technologies predict demand patterns and optimize inventory levels, reducing waste and improving customer satisfaction.

- Advanced Warehouse Management Software: Provides real-time visibility into inventory and operations, enabling informed decision-making.

Research from ShipScience Technology Trends indicates that automation can reduce operational costs by up to 30% while increasing throughput by 25%.

Best Practices for Inventory Management in East Coast Warehouses

Effective inventory management is crucial for supply chain optimization. Best practices include:

- Regular Cycle Counts: Conducting frequent inventory counts helps maintain accuracy and prevent discrepancies.

- Inventory Audits: Regular audits identify and reduce excess inventory, minimizing storage costs.

- Data-Driven Forecasting: Utilizing data and analytics to accurately forecast demand ensures optimal inventory levels.

- Lean Inventory Practices: Implementing lean principles reduces waste and increases supply chain efficiency.

- Clear Communication Channels: Ensuring all departments are aligned regarding inventory levels and demand forecasts prevents issues and improves coordination.

According to the 2023 Inventory Management Study, businesses adopting these best practices have seen a 15% reduction in inventory holding costs.

Streamlining Shipping and Receiving Processes with East Coast Warehousing

Efficient shipping and receiving are vital for maintaining a smooth supply chain. Strategies to streamline these processes include:

- Transportation Management Systems (TMS): Invest in TMS to manage logistics effectively and reduce transportation costs.

- Real-Time Tracking: Implementing real-time tracking provides end-to-end visibility of shipments, improving management and performance monitoring.

- Automated Shipping Processes: Automation can expedite shipping processes, reduce errors, and enhance overall efficiency.

- Optimized Receiving Procedures: Streamlining receiving processes ensures timely and accurate handling of incoming goods.

Data from the 2023 Shipping & Receiving Optimization Report shows that businesses using advanced TMS experience a 10% reduction in shipping costs and a 20% improvement in delivery times.

The Importance of Flexibility in Adapting to Changing Market Demands

Flexibility is crucial in today's dynamic business environment. Businesses must adapt quickly to shifting market conditions and evolving customer demands to stay competitive. In East Coast warehousing, this flexibility can be achieved by:

- Scalable Warehouse Solutions: Choosing warehouses that can scale operations based on demand fluctuations.

- Agile Supply Chain Practices: Implementing agile methodologies allows for rapid response to changes in the market.

- Diverse Transportation Options: Utilizing multiple transportation modes ensures adaptability in delivery schedules and routes.

- Continuous Improvement: Regularly assessing and improving warehouse processes to enhance flexibility and responsiveness.

According to the 2023 Supply Chain Flexibility Report, companies with flexible supply chains are 35% more likely to recover quickly from disruptions.

Cost Savings and Increased Profitability with East Coast Warehousing Solutions

East Coast warehousing solutions offer significant cost savings and profitability enhancements through:

- Improved Logistics: Efficient warehousing reduces transportation costs and enhances delivery speed.

- Faster Delivery Times: Proximity to major markets ensures quicker fulfillment, enhancing customer satisfaction and repeat business.

- Streamlined Operations: Optimized warehousing processes minimize waste and operational inefficiencies, reducing overall costs.

- Technology Integration: Leveraging advanced technologies like automation and AI leads to long-term cost savings and productivity gains.

Businesses that proactively optimize their supply chains and adopt technological advancements can expect substantial cost savings and increased profitability. The 2023 Cost Savings Report highlights that companies using strategic East Coast warehousing have realized an average of 12% cost reduction in their logistics operations.

Case Studies: Companies That Have Successfully Maximized Efficiency with East Coast Warehousing

Several companies have effectively leveraged East Coast warehousing to enhance their supply chain efficiency:

- Amazon: With multiple fulfillment centers on the East Coast, Amazon ensures rapid delivery and efficient inventory management, contributing to its reputation for fast shipping.

- Crown Equipment Corporation: By utilizing East Coast warehouses, Crown Equipment has optimized its distribution network, reducing delivery times and improving customer satisfaction.

- Pinnacle Logistics: Pinnacle Logistics has adopted innovative strategies in its East Coast facilities, such as automation and real-time tracking, to maximize operational efficiency and maintain a competitive edge.

These case studies demonstrate the tangible benefits of strategic warehousing locations and the impact of adopting best practices and advanced technologies.

Future Trends in the East Coast Warehousing Industry

The East Coast warehousing industry is poised for significant advancements in the coming years, driven by:

- Increased Automation: Continued adoption of automated systems and robotics to enhance warehouse efficiency.

- Robotics and AI Integration: Expanding the use of artificial intelligence and machine learning to optimize operations and predict market trends.

- Advancements in Transportation Management Systems: Enhancing TMS capabilities for better logistics coordination and cost management.

- Sustainability Initiatives: Implementing eco-friendly practices and technologies to reduce the environmental impact of warehousing operations.

Embracing these trends will enable businesses to stay ahead of the competition and achieve long-term success. The 2023 Future Trends Report predicts a 25% increase in automation adoption in East Coast warehouses by 2025.

Navigating Regulatory Compliance and Safety Requirements in East Coast Warehouses

Compliance with regulatory and safety standards is essential for businesses operating East Coast warehouses. Key considerations include:

- Worker Safety Standards: Adhering to Occupational Safety and Health Administration (OSHA) regulations to ensure a safe working environment.

- Environmental Protection: Complying with Environmental Protection Agency (EPA) guidelines to minimize the environmental impact of operations.

- Product Safety Regulations: Ensuring that stored products meet all relevant safety and quality standards.

- Local Regulations: Understanding and complying with state and municipal regulations that may affect warehousing operations.

Non-compliance can result in hefty fines and legal complications. Therefore, businesses must stay informed about applicable regulations and implement robust compliance programs. Resources such as the ShipScience Compliance Guide provide valuable insights and updates on relevant laws and standards.

Tips for Selecting the Right Third-Party Logistics (3PL) Provider on the East Coast

Choosing the right third-party logistics (3PL) provider is critical for maximizing efficiency and profitability in East Coast warehousing operations. Consider the following tips:

- Evaluate Experience and Capabilities: Assess the 3PL's expertise in your specific industry and their ability to handle your warehousing and logistics needs.

- Pricing Structure: Understand the 3PL's pricing model and ensure it aligns with your budget and financial goals.

- Customer Service Commitment: Look for 3PL providers that prioritize customer satisfaction and have a track record of reliable service.

- Industry-Specific Experience: Providers with experience in your industry can offer tailored solutions and better understand your unique requirements.

- Technological Integration: Ensure the 3PL uses advanced technologies like WMS and TMS for seamless integration with your systems.

Platforms like ShipScience's 3PL Directory can help businesses identify and compare top 3PL providers based on these criteria.

Conclusion: Why Your Business Should Consider East Coast Warehousing as a Strategic Advantage

East Coast warehousing offers a strategic advantage for businesses aiming to maximize efficiency, optimize supply chains, and streamline operations for enhanced profitability. Strategic locations with access to robust transportation networks, coupled with advanced technologies and best practices in inventory management and logistics, enable businesses to achieve significant cost savings and operational efficiencies. Moreover, the flexibility and scalability offered by East Coast warehouses, along with access to a skilled workforce, provide a competitive edge in a crowded market. By leveraging these advantages, businesses can position themselves for long-term success and sustained profitability.