Measuring the Cost of Direct-to-Customer Orders: Why It Matters for E-Commerce Operations

In today's fast-paced e-commerce industry, meeting customer expectations for speedy and accurate delivery of products has become increasingly important. With the rise of direct-to-customer (DTC) orders, e-commerce businesses are faced with the challenge of managing the costs associated with fulfilling these orders efficiently. Accurate measurement of DTC order costs is crucial in ensuring the profitability and sustainability of an e-commerce operation.

The Importance of Accurately Measuring Direct-to-Customer Order Costs

Accurately measuring the costs associated with DTC orders provides e-commerce businesses with a detailed understanding of the expenses incurred in fulfilling these orders from start to finish. Such expenses include warehousing, inventory management, order processing and packaging, and last-mile delivery costs.

According to a Statista report, logistics costs account for approximately 15% of total sales in the e-commerce sector. By understanding the costs involved in the fulfillment of DTC orders, e-commerce businesses can identify areas of inefficiency and potential cost savings, ultimately improving their profitability. Additionally, accurate cost measurement allows e-commerce businesses to make informed decisions about pricing strategies, identifying products with the highest profit margins and adjusting prices accordingly.

Another benefit of accurately measuring DTC order costs is the ability to evaluate the effectiveness of marketing campaigns. By tracking the costs associated with fulfilling orders generated by specific marketing efforts, businesses can determine the return on investment (ROI) for each campaign and adjust their marketing strategies accordingly.

Furthermore, accurate cost measurement can help e-commerce businesses optimize their supply chain management. By identifying the most cost-effective suppliers and shipping methods, businesses can reduce their overall costs and improve their bottom line.

Components of Direct-to-Customer Order Costs

- Inventory Costs – Includes the cost of purchasing, storing, and managing inventory.

- Order Processing Costs – Covers pick and pack labor, packaging materials, and order accuracy verification.

- Last-Mile Delivery Costs – The expense of delivering products to the customer's doorstep.

- Returns Processing Costs – Costs associated with processing returned products.

Additionally, customer service costs are crucial to consider. This includes hiring and training customer service representatives and providing support through various channels such as phone, email, and chat.

Marketing and advertising costs should also be factored in, including the creation and running of ads, as well as brand promotion through channels like social media and influencer marketing.

Calculating the Total Cost of Direct-to-Customer Orders

The total cost of fulfilling a DTC order involves summing all expenses associated with the various stages of the order process. This includes the cost of goods sold (COGS), storage and handling costs, delivery and returns costs. To determine COGS, businesses must factor in the cost of the product sold, including materials, labor, and overhead expenses.

Storage and handling costs typically encompass rent, utilities, and labor costs for managing inventory. Delivery and returns costs include packaging materials, shipping, handling, and restocking fees for returned items.

It is essential for businesses to accurately calculate the total cost of fulfilling DTC orders to set appropriate pricing and ensure profitability. Beyond direct costs, indirect costs such as marketing and customer service expenses necessary to attract and retain customers should also be considered.

According to a study by Harvard Business Review, returns can account for up to 30% of total sales in some e-commerce sectors. To minimize the impact of returns and exchanges, businesses should establish clear policies and improve product descriptions and images to reduce the likelihood of customer dissatisfaction.

Strategies for Reducing Direct-to-Customer Order Costs

- Optimizing Inventory Management – Invest in software that streamlines inventory processes, reducing handling costs.

- Implementing Automated Order Processing and Packaging Systems – Minimize labor-intensive tasks, reducing costs.

- Exploring Alternative Shipping Options – Identify the most cost-effective shipping methods to lower delivery costs.

- Offering Self-Service Returns – Reduce returns processing costs by enabling customers to manage returns independently.

Another effective strategy is to implement a minimum order value policy, encouraging customers to purchase more items in a single order. This reduces the overall cost of shipping and handling per item. Additionally, offering free shipping for orders that meet a certain value threshold can incentivize customers to purchase more items, further decreasing fulfillment costs.

The Role of Technology and Data Analytics in Managing Direct-to-Customer Order Costs

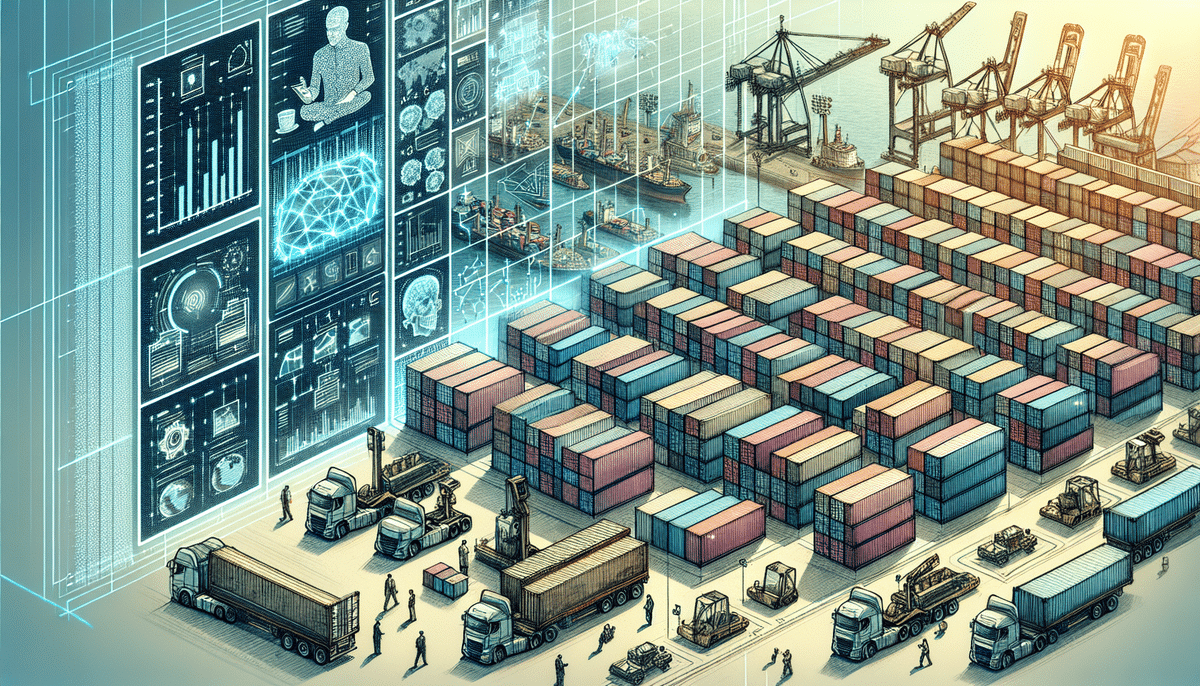

The adoption of technology is transformative in the management and measurement of DTC order costs. Implementing advanced software solutions enables e-commerce businesses to streamline processes, reduce handling costs, minimize errors, and analyze data for more informed decision-making.

Automation, machine learning, and artificial intelligence are increasingly vital in generating insights that drive improvements in DTC order cost management. For instance, IBM highlights how machine learning can predict demand patterns, allowing businesses to optimize inventory levels and reduce excess stock.

Real-time inventory tracking is another technological advantage. It allows businesses to maintain optimal inventory levels, reducing the risk of overstocking or stockouts. This leads to more informed decisions about when to reorder products, minimizing excess inventory and associated costs.

Automating the order fulfillment process, including order processing, picking, packing, and shipping, can significantly reduce the time and labor required to fulfill orders. This automation not only speeds up the process but also minimizes the risk of errors and delays, leading to improved customer satisfaction and increased sales.

Common Mistakes and Best Practices in Measuring Direct-to-Customer Order Costs

When measuring DTC order costs, e-commerce businesses should avoid common pitfalls that can distort their understanding of expenses:

- Failing to Separate DTC Order Costs from Other Expenses – Ensure that DTC costs are tracked independently from traditional retail expenses.

- Incomplete Cost Accounting – Account for all costs associated with DTC orders, including inventory management, shipping, returns processing, and customer service.

- Ignoring Shipping Cost Variability – Accurately calculate shipping costs based on product size, weight, and destination.

- Overlooking Customer Service Costs – Include costs related to hiring, training, and maintaining customer service teams.

Implementing best practices can enhance cost measurement accuracy:

- Regular Data Review and Analysis – Continuously monitor and analyze cost data to identify trends and areas for improvement.

- Automated Processes – Use automation to streamline order fulfillment and returns processing, reducing manual errors and labor costs.

- Alternative Shipping Options – Explore various shipping methods to find the most cost-effective solutions that meet customer expectations.

Balancing Customer Experience with Direct-to-Customer Order Cost Management

While managing and controlling DTC order expenses is essential, e-commerce businesses must also prioritize delivering an exceptional customer experience. Cost-cutting measures that compromise quality can drive away customers and reduce long-term sales revenues.

Strategies to balance cost management with customer satisfaction include:

- Investing in Quality Customer Service – Providing responsive and helpful customer service can enhance loyalty and justify slightly higher costs.

- Improving Product Descriptions and Imagery – Accurate and appealing product information reduces misunderstandings and returns.

- Streamlining the Order Process – A smooth and efficient order process enhances the customer experience while controlling costs.

- Offering Flexible Shipping Options – Providing choices such as expedited shipping or free shipping thresholds can meet diverse customer needs without excessive costs.

The Future of E-Commerce Operations and the Role of Measuring Direct-to-Customer Order Costs

The e-commerce industry is continually evolving, with DTC orders becoming increasingly central to business strategies. Effective management and control of DTC order costs will be paramount to the profitability and sustainability of e-commerce businesses in the future.

Advancements in artificial intelligence (AI) and machine learning will play significant roles in enhancing DTC order cost management. These technologies can provide deeper insights into consumer behavior, predict demand more accurately, and automate complex logistics processes.

Moreover, the integration of omnichannel strategies, where businesses provide a seamless shopping experience across multiple platforms, will necessitate more sophisticated cost measurement and management techniques. Ensuring consistency and efficiency across channels will help maintain profitability while meeting diverse customer expectations.

In conclusion, accurately measuring and managing the cost of DTC orders is essential to the profitability and sustainability of e-commerce businesses. By understanding the various costs involved, identifying areas of inefficiency, and leveraging technology, e-commerce businesses can optimize their fulfillment processes and drive long-term success. The future of e-commerce operations lies in the strategic management of DTC order costs, supported by technological advancements that enable continuous improvement and adaptation to changing market dynamics.