Importance of Accuracy and Integrated Dimensioning in Logistics

Why Accuracy Matters in Weighing and Measuring Packages

Accuracy is paramount in the logistics industry, where even minor errors can lead to significant time-consuming and costly issues. Shipping items that weigh more than declared can impact the transportability of goods, while incorrectly sized packages may result in damaged products. Depending on the scale of the operation, these errors can cost businesses thousands of dollars annually.1 Therefore, selecting the right measuring system is vital.

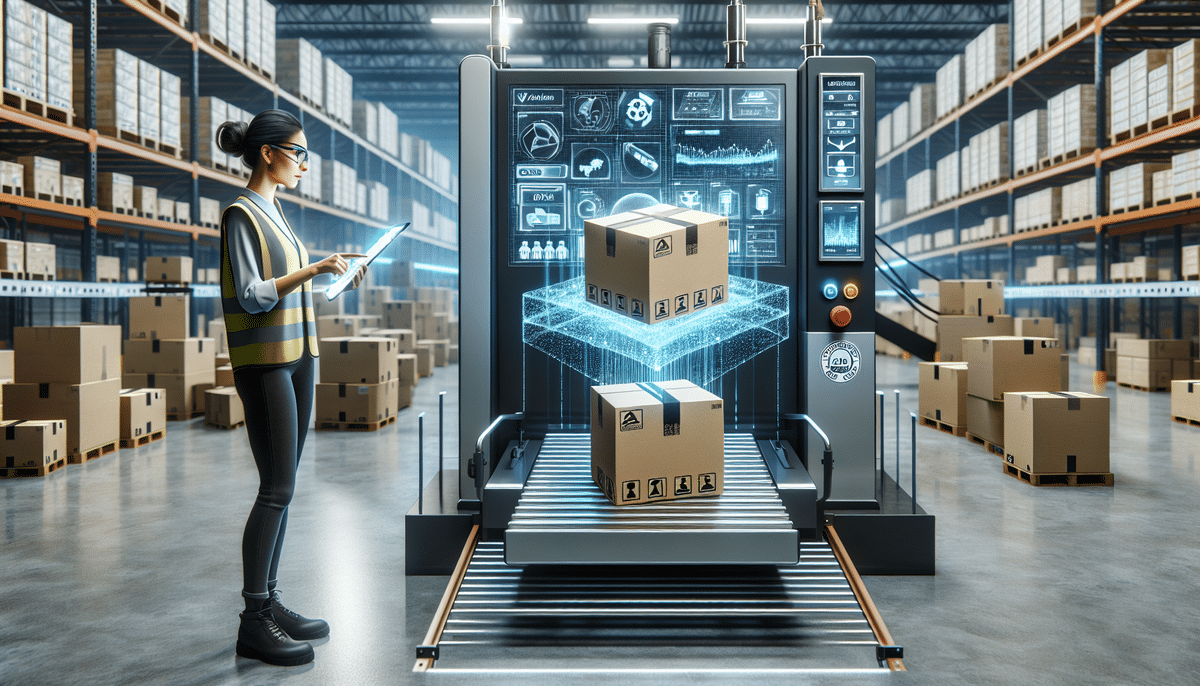

One common cause of inaccurate measurements is human error. Even experienced workers can make mistakes when manually measuring and weighing packages. This is why many logistics companies are adopting automated systems that utilize advanced technology to ensure precision. Automated systems can measure and weigh packages quickly and accurately, reducing the risk of errors and enhancing efficiency. Additionally, these systems provide real-time data on package weight and size, enabling informed decisions about shipping and handling.

The Role of Integrated Dimensioning in the Logistics Industry

Dimensioning is a critical component of accurate weighing, and it has become a standard practice in the logistics industry. A dimensioning system measures the length, height, and width of a package, then calculates its volume. This information is essential for determining the optimal mode of transport and ensuring compliance with loading limit regulations.

Integrated dimensioning systems have transformed the logistics landscape by providing real-time data on package dimensions and weight. This data is crucial for efficient warehouse management, enabling accurate inventory tracking and space optimization. Moreover, integrated dimensioning reduces the risk of errors and delays in the shipping process, ultimately enhancing customer satisfaction.2

Furthermore, using integrated dimensioning systems can lead to significant cost savings for logistics companies. By accurately measuring package dimensions and weight, companies can avoid overpaying for shipping and reduce the risk of fines for non-compliance with regulations. According to industry reports, companies can save up to 20% in shipping costs by implementing precise weighing and dimensioning systems.3

Comparing Weighing and Dimensioning Systems

Understanding the Features of Mettler Toledo CSN840

The Mettler Toledo CSN840 is a high-performance weighing and dimensioning system that integrates advanced weighing technology with dimensioning capabilities. It boasts a high weigh capacity and a low profile, facilitating easy integration into existing systems. Key features include conveyor belt speed control, automatic identification, dimensioning capabilities, and a real-time camera system for imaging packages.

Additionally, the CSN840 offers a user-friendly interface that allows for easy operation and customization. It can store and recall product information, enhancing efficiency for businesses handling a diverse range of products. The system is built for durability and reliability, requiring minimal maintenance. With its versatile and efficient design, the Mettler Toledo CSN840 is an ideal solution for businesses demanding precise weighing and dimensioning capabilities.

Navigating the Benefits of NTEP Certified Scales

NTEP certified scales are designed to ensure that weighing devices produce dependable and accurate results. They are regulated by the National Conference on Weights and Measures in the United States, adhering to stringent standards. The NTEP certification process involves rigorous testing to verify the accuracy and reliability of the weighing system. An NTEP certified scale is an excellent choice for businesses that require high levels of accuracy and consistency in their weighing and measurement processes.

One of the primary benefits of using an NTEP certified scale is compliance with legal requirements. Industries such as food and pharmaceuticals are subject to strict regulations regarding the accuracy of their weighing and measurement processes. Utilizing an NTEP certified scale ensures that businesses meet these requirements, thereby avoiding potential legal issues. Moreover, NTEP certified scales often come with warranties and technical support, providing businesses with peace of mind and assistance in case of any issues.4

Technological Advancements in Weighing and Dimensioning

A Closer Look at Weighing and Dimensioning Technology

Weighing and dimensioning systems have significantly evolved, with advancements in technology enabling higher levels of accuracy. Automated systems improve efficiency, reduce human error, and increase productivity. Modern systems seamlessly integrate with existing conveyor systems, ensuring smooth incorporation into current operations.

A key advantage of using weighing and dimensioning technology is the ability to capture and analyze data. Advanced software allows businesses to track and monitor package weight, size, and other critical metrics. This data aids in optimizing shipping processes, identifying areas for improvement, and making informed decisions about inventory management. Some systems also offer real-time tracking and reporting, enabling businesses to quickly address any issues that arise during the shipping process.5

Choosing the Right Weighing and Dimensioning System for Your Business

How to Select the Right Scale for Your Business Needs

Choosing the appropriate weighing and dimensioning system is critical to the success of a logistics operation. Factors to consider include the scale of operations, the size and weight of packages, and the frequency of use. The right system can lead to cost savings, minimize the risk of errors, and enhance overall efficiency.

One essential factor is the level of accuracy required for your business. For instance, businesses shipping high-value items may need scales with higher precision to ensure accurate measurements. Additionally, if your operations involve shipping a wide range of package sizes and weights, a system with dynamic weighing capabilities, which automatically adjusts to each package's size and weight, would be beneficial. By evaluating these factors, businesses can select a weighing and dimensioning system that aligns with their specific needs and goals.

Evaluating the Precision and Durability of Mettler Toledo CSN840 and NTEP Certified Scales

The Mettler Toledo CSN840 and NTEP certified scales are renowned for their high levels of precision and durability. These systems can measure weight in increments as small as 0.01g and are capable of accurately weighing items in large quantities. Their robust design ensures they can withstand daily usage in even the busiest commercial operations.

Despite their similarities, there are key differences between Mettler Toledo and NTEP certified scales. Mettler Toledo scales are celebrated for their advanced software and user-friendly interfaces, making them a popular choice for laboratories and research facilities. In contrast, NTEP certified scales are legally required for commercial use in the United States, guaranteeing adherence to strict accuracy and reliability standards.6 Ultimately, the choice between these two types of scales depends on the specific requirements and priorities of the user.

Cost and Efficiency Impacts of Accurate Measurements

The Impact of Accurate Weighing and Sizing on Shipping Costs

Accurate weighing and sizing of packages are instrumental in minimizing shipping errors, which can significantly affect shipping costs—a major concern for businesses of all sizes. Even a minor overcharge on shipping fees can accumulate to substantial amounts over time. Ensuring that your weighing and measurement systems are precise helps businesses better manage their shipping expenses.

Moreover, accurate weighing and sizing enhance customer satisfaction. When packages are shipped with the correct weight and dimensions, customers experience fewer delays and unexpected fees, leading to a more positive experience and increased loyalty. Additionally, precise measurements help businesses avoid costly returns due to incorrect package sizes or weights, further reducing expenses and improving overall efficiency.

Comparing the Cost-Effectiveness of Mettler Toledo CSN840 and NTEP Certified Scales with Integrated Dimensioning

Cost-effectiveness is a critical consideration in the logistics industry. The Mettler Toledo CSN840, with its advanced design, is generally more expensive compared to NTEP certified scales. However, the CSN840's sophisticated features, such as in-motion dimensioning and a camera system, make it a superior choice for high-volume, fast-paced operations. For businesses with smaller-scale operations, NTEP certified scales may offer a more economical solution without compromising on essential accuracy and reliability.

Addressing Misconceptions and Legal Requirements

Addressing Common Myths About Weighing Scales and Integrated Dimensioning Systems

There are several misconceptions surrounding weighing scales and dimensioning systems. A prevalent myth is that these systems are overly complicated, difficult to maintain, and require technical expertise to operate. In reality, most modern weighing systems are designed for ease of use, allowing even non-technical employees to operate them efficiently. Maintenance is typically straightforward, involving regular cleaning and calibration. Additionally, most manufacturers provide clear instructions and robust online support to assist users.

Understanding the Legal Requirements for Accurate Weight and Size Measurements in Different Industries

The logistics industry is subject to various regulations that mandate specific rules and processes. These rules vary across industries, and businesses must comply to avoid legal repercussions. In the USA, the National Institute of Standards and Technology (NIST) establishes measurement standards and regulations applicable to most sectors. However, specific industries have additional guidelines, making it essential for businesses to understand and adhere to these standards to prevent penalties and other legal complications.7

Maintaining Your Weighing and Sizing Equipment for Optimal Performance

Tips for Maintaining Your Weighing and Sizing Equipment

Proper maintenance of weighing and sizing equipment is crucial for ensuring accuracy and consistency. Regular cleaning and calibration are essential components of the maintenance process. Additionally, routinely inspecting and testing belts, sensors, and other key components can help detect early warning signs of potential issues, preventing costly failures and downtime.

In Conclusion

Choosing the right weighing and dimensioning system requires careful consideration of a business's unique needs, including package types, usage frequency, and the required level of accuracy. The Mettler Toledo CSN840 and NTEP certified scales are both high-performing options for businesses seeking accurate and reliable weighing and measurement systems. With proper maintenance, these systems can provide years of dependable performance and cost savings for logistics operations of all scales.