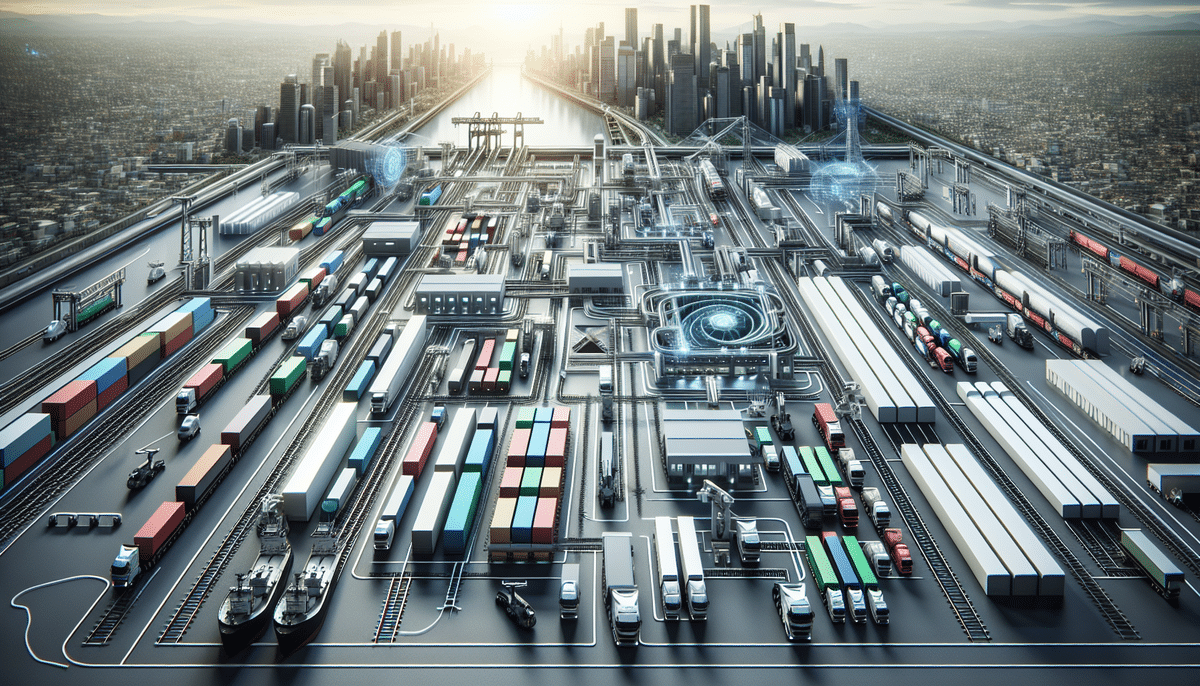

Optimizing Domestic Supply Chains for Maximum Efficiency

Efficient domestic supply chains are critical to the success of any business, regardless of its size or industry. Optimizing these supply chains can lead to reduced costs, increased productivity, better inventory management, enhanced customer satisfaction, and improved profitability. In this article, we explore various strategies and best practices for maximizing efficiency in domestic supply chains, address the challenges, and highlight future opportunities in this sector.

Understanding the Domestic Supply Chain Landscape

Domestic supply chains encompass the movement of goods and services within a country, involving a series of interconnected activities from sourcing raw materials to delivering finished products to end customers. Key stakeholders include suppliers, manufacturers, distributors, retailers, and logistics providers. A comprehensive understanding of the entire process and its stakeholders is essential for optimization.

Key Stakeholders in Domestic Supply Chains

- Suppliers: Provide the raw materials or components necessary for production.

- Manufacturers: Convert raw materials into finished products.

- Distributors: Handle the storage and transportation of goods.

- Retailers: Sell the final products to consumers.

- Logistics Providers: Manage the movement and storage of goods throughout the supply chain.

Challenges in Domestic Supply Chain Management

One of the primary challenges in managing a domestic supply chain is ensuring timely delivery of goods and services. Effective coordination and communication among all stakeholders are crucial. Additionally, having contingency plans to mitigate disruptions—such as natural disasters or transportation strikes—is vital for maintaining supply chain resilience.

Reducing costs while maintaining quality is another critical aspect of supply chain optimization. Strategies include implementing lean manufacturing processes, leveraging technology to streamline operations, and negotiating favorable contracts with suppliers and logistics providers. Continuous monitoring and improvement enable businesses to gain a competitive advantage and better meet customer needs.

The Importance of Efficient Domestic Supply Chains

Efficient domestic supply chains are essential for achieving optimal productivity and profitability. By reducing transportation costs, minimizing lead times, and improving inventory management, businesses can save time and money while maintaining a competitive edge. Optimized supply chains also enhance customer satisfaction, as timely and accurate delivery is crucial for maintaining positive relationships.

Economic Benefits

According to a report by the U.S. Census Bureau, efficient supply chain management can reduce operational costs by up to 20%, significantly impacting a company's bottom line.

Environmental Sustainability

Moreover, efficient supply chains contribute to environmental sustainability. Minimizing transportation distances and optimizing delivery routes can reduce a business's carbon footprint, enhancing brand image and appealing to environmentally conscious customers. The Environmental Protection Agency emphasizes the importance of sustainable practices in reducing environmental impact.

Agility and Responsiveness

Additionally, efficient supply chains enable businesses to respond swiftly to changes in demand and market conditions. A streamlined and agile supply chain allows for adaptation to new trends and opportunities, avoiding stockouts or overstocking and helping businesses stay ahead of the competition.

Streamlining Domestic Supply Chain Processes

Maximizing efficiency in domestic supply chains involves streamlining processes to eliminate waste, optimize workflows, and reduce lead times. Implementing lean principles—which involve mapping the entire supply chain and identifying areas for improvement—can minimize delays and reduce costs.

Lean Manufacturing

Lean manufacturing focuses on minimizing waste without sacrificing productivity. Techniques such as Value Stream Mapping (VSM) help identify non-value-added activities and streamline processes.

Technology and Automation

Investing in technology and automation is another crucial aspect. Implementing software for inventory management, order tracking, and transportation planning can automate repetitive tasks, freeing up time for strategic activities. Technology also provides real-time visibility into the supply chain, allowing businesses to quickly identify and address issues.

Reducing Costs in Domestic Supply Chains

Cost reduction is a fundamental objective in optimizing domestic supply chains. Consolidating orders and shipments can lower transportation costs, minimize damage risks, and enhance tracking capabilities. Additionally, negotiating better rates with freight carriers through market trend awareness and utilizing freight management software can lead to significant savings.

Consolidation Strategies

By consolidating shipments, businesses can achieve economies of scale, reducing the per-unit transportation cost. This approach also decreases the likelihood of damaged goods and simplifies inventory tracking.

Negotiating with Suppliers

Establishing strong relationships with suppliers can lead to better pricing and terms. Leveraging data analytics to understand market trends can provide leverage during negotiations, ensuring more favorable contracts.

Leveraging Technology to Optimize Domestic Supply Chains

Technology is a critical enabler in optimizing domestic supply chains. Integrating Enterprise Resource Planning (ERP) systems streamlines workflows, improves tracking, and automates manual tasks, enhancing accuracy and reducing errors. Cloud-based software and analytics tools provide insights into critical data, allowing informed decision-making and proactive risk management.

Internet of Things (IoT)

The use of Internet of Things (IoT) devices can track the location, condition, and performance of products, equipment, and vehicles in real-time. This data optimizes routes, predicts maintenance needs, and improves overall efficiency.

Blockchain Technology

Blockchain technology enhances transparency and traceability in the supply chain, ensuring products are ethically sourced and delivered accurately. According to a study by Forbes, blockchain can reduce supply chain costs by up to 20% by increasing transparency and reducing fraud.

Analyzing Data to Improve Domestic Supply Chain Performance

Data analysis is essential for optimizing domestic supply chains. Tracking key metrics such as lead time, inventory turnover, and delivery performance helps identify areas for improvement. Predictive analytics can forecast demand patterns, anticipate potential disruptions, and support strategic decision-making to enhance supply chain resilience.

Key Performance Indicators (KPIs)

- Lead Time: The total time taken from order placement to delivery.

- Inventory Turnover: How often inventory is sold and replaced over a period.

- Delivery Performance: The accuracy and timeliness of deliveries.

Predictive Analytics

Using machine learning algorithms, businesses can predict future demand, identify potential supply chain disruptions, and optimize inventory levels. According to McKinsey & Company, companies that effectively use predictive analytics can improve their supply chain efficiency by up to 25%.

Managing Risks in Domestic Supply Chains

Risk management is crucial for optimizing domestic supply chains. Identifying potential risks—such as supplier disruptions, natural disasters, or geopolitical instability—and developing contingency plans can minimize disruptions and ensure operational continuity. Increasing transparency and enhancing communication with supply chain partners build collaborative relationships, reducing the risk of conflicts and misunderstandings.

Diversifying the Supplier Base

Diversifying the supplier base is an effective risk management strategy. Relying on multiple suppliers for key materials or components reduces the impact of disruptions from any single supplier. This diversification can also foster competition among suppliers, leading to better pricing and quality. However, balancing diversification benefits with the costs of managing multiple suppliers is essential.

Contingency Planning

Developing comprehensive contingency plans ensures that businesses can quickly adapt to unexpected disruptions. This involves identifying critical suppliers, alternative transportation routes, and backup inventory sources to maintain operations during crises.

Enhancing Collaboration and Communication in Domestic Supply Chains

Collaboration and communication are vital for achieving maximum efficiency in domestic supply chains. Establishing open communication channels, sharing information, and working towards common goals build trust and lead to better outcomes. Adopting collaborative planning and forecasting methods, which involve sharing data and jointly developing forecasts, improves supply chain planning and reduces uncertainties.

Supplier Relationship Management (SRM)

Implementing a Supplier Relationship Management (SRM) program fosters strong relationships with suppliers by understanding their capabilities and limitations. Collaborative SRM programs can improve product quality, reduce lead times, and increase overall supply chain efficiency.

Collaborative Planning, Forecasting, and Replenishment (CPFR)

CPFR involves coordinating demand forecasts and production plans across the supply chain. This collaboration leads to more accurate demand predictions, reduced inventory costs, and improved service levels.

Creating a Sustainable Domestic Supply Chain Strategy

Sustainability is increasingly important in domestic supply chains. Implementing sustainable practices—such as reducing waste, minimizing carbon footprint, and adopting circular economy models—not only minimizes environmental impact but also enhances the social and economic dimensions of sustainability.

Waste Reduction

Implementing recycling programs, reducing packaging materials, and optimizing production processes can significantly decrease waste, leading to cost savings and environmental benefits.

Carbon Footprint Minimization

Utilizing energy-efficient transportation methods, optimizing logistics routes, and investing in renewable energy sources can substantially reduce a company's carbon footprint. The Intergovernmental Panel on Climate Change (IPCC) highlights the critical role of supply chains in achieving global carbon reduction targets.

Circular Economy Models

Adopting circular economy principles—where products are designed for reuse, recycling, and remanufacturing—can create closed-loop supply chains that enhance sustainability and reduce dependency on finite resources.

Measuring and Monitoring the Performance of Domestic Supply Chains

Measuring and monitoring supply chain performance is an ongoing process essential for continuous improvement. Tracking key performance indicators (KPIs) such as on-time delivery, inventory accuracy, and order cycle time evaluates the effectiveness of supply chain strategies and identifies areas for enhancement.

Regular Audits

Conducting regular audits ensures compliance with laws and regulations, identifying potential risks and areas needing attention. Audits also provide insights into the efficiency and effectiveness of current supply chain practices.

Data-Driven Insights

Utilizing data-driven insights from performance measurements supports informed decision-making and strategic planning. Advanced analytics tools can process large datasets to uncover trends, patterns, and actionable insights.

Addressing Challenges in Optimizing Domestic Supply Chains

Optimizing domestic supply chains involves overcoming several challenges, including managing the complexity and uncertainty inherent in supply chain operations. Disruptions from natural disasters, political instability, or trade disputes can significantly impact operations.

Building Resilient Supply Chains

Developing resilient supply chains involves creating flexible systems that can adapt to changes and recover quickly from disruptions. Strategies include diversifying suppliers, investing in flexible manufacturing systems, and enhancing real-time visibility across the supply chain.

Maintaining Strong Relationships with Partners

Maintaining close relationships with supply chain partners fosters collaboration, trust, and mutual support during challenging times. Regular communication and joint problem-solving initiatives can mitigate the impact of unforeseen events.

Best Practices for Optimizing Domestic Supply Chains

While there is no one-size-fits-all solution for supply chain optimization, several best practices can help organizations achieve maximum efficiency:

- Integrate advanced technology and automation.

- Adopt lean principles to eliminate waste.

- Utilize data analytics for informed decision-making.

- Establish collaborative relationships with stakeholders.

- Implement sustainable practices to enhance environmental and economic performance.

Continuous Improvement

Adopting a culture of continuous improvement ensures that supply chain processes are regularly evaluated and enhanced. Techniques such as Six Sigma and Total Quality Management (TQM) can systematically reduce defects and improve efficiency.

Case Studies of Successful Domestic Supply Chain Optimization

Several successful case studies highlight the potential benefits of optimizing domestic supply chains. For instance, a leading automotive manufacturer implemented a comprehensive lean management program, resulting in a 20% reduction in lead time, a 15% increase in productivity, and a 25% decrease in inventory.

Another example is a grocery retailer that adopted a cloud-based communication system, leading to an 8% increase in sales and a 10% reduction in transportation costs. These cases demonstrate that organizations of all sizes and sectors can achieve significant results through supply chain optimization.

Future Trends and Opportunities in Domestic Supply Chain Optimization

The field of domestic supply chain optimization is evolving, with several emerging trends and opportunities:

- Blockchain Technology: Enhancing transparency and traceability.

- Increased Automation: Streamlining operations and reducing manual errors.

- Sustainable Supply Chains: Focusing on environmental and social responsibility.

- Growth of E-Commerce: Adapting to changing consumer behaviors and demands.

Staying abreast of these trends and leveraging new technologies and practices will help organizations remain competitive and achieve maximum efficiency in their domestic supply chains.

Conclusion

Optimizing domestic supply chains for maximum efficiency is essential for achieving success in today's competitive marketplace. By adopting best practices, leveraging technology and analytics, and building collaborative relationships, organizations can realize significant benefits, including reduced costs, improved productivity, and enhanced customer satisfaction.

Addressing challenges and seizing opportunities in supply chain optimization enables businesses to build resilient and sustainable domestic supply chains. These optimized supply chains can meet the needs of today’s customers while preparing for future challenges and opportunities, ensuring long-term success and growth.

For more insights and resources on supply chain optimization, visit ShipScience.