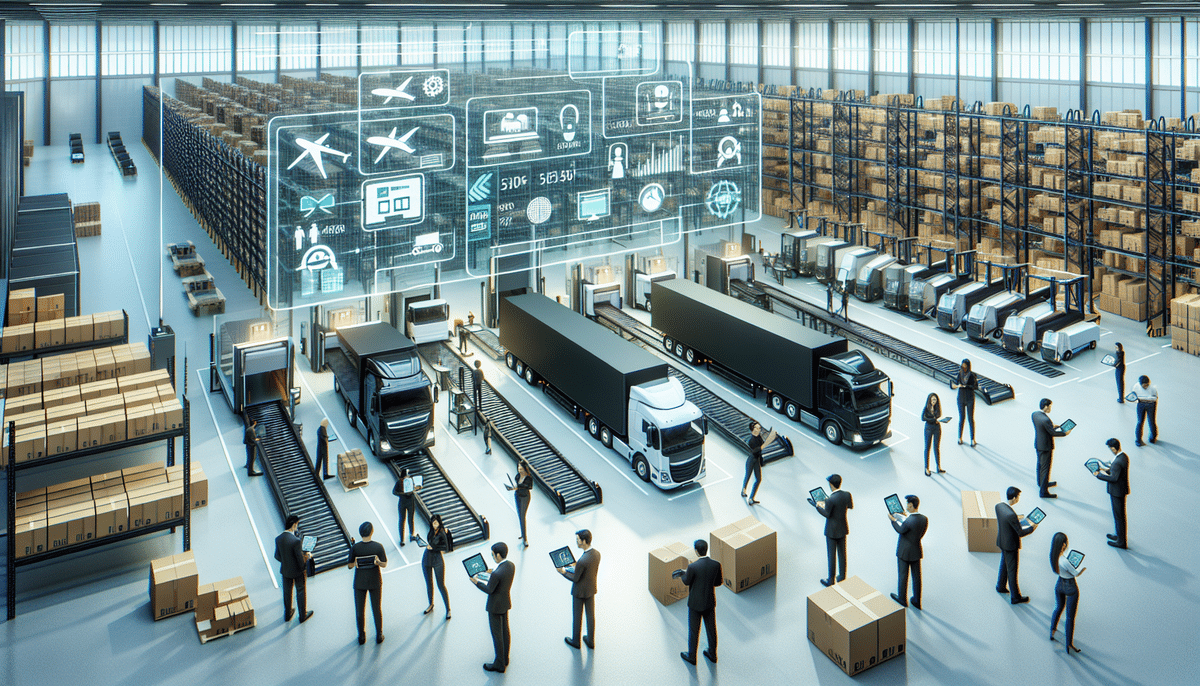

Understanding Dock Scheduling in E-Commerce Logistics

Dock scheduling is a critical component of e-commerce logistics, encompassing the strategic planning and management of incoming and outgoing shipments at a warehouse or distribution center. By effectively coordinating the timing of deliveries and dispatches, dock scheduling ensures smooth operations and optimal use of resources.

What is Dock Scheduling?

Dock scheduling involves organizing the arrival and departure of trucks and other delivery vehicles to and from a warehouse. This process helps in managing the flow of goods, minimizing wait times, and preventing congestion at loading docks. Efficient dock scheduling ensures that shipments are handled promptly, reducing delays and enhancing overall operational efficiency.

The Role of Dock Scheduling in the Supply Chain

Dock scheduling plays a pivotal role in the supply chain by ensuring that goods move seamlessly from suppliers to warehouses and ultimately to customers. It aids in synchronizing various supply chain activities, such as inventory management, order fulfillment, and transportation planning, thereby enhancing the reliability and responsiveness of the logistics network.

Benefits of Effective Dock Scheduling

Improved Efficiency and Reduced Costs

Implementing a robust dock scheduling system can significantly boost operational efficiency. According to a report by McKinsey & Company, optimized logistics processes can reduce operational costs by up to 20%. Efficient dock scheduling minimizes idle times for trucks and staff, leading to cost savings and higher productivity.

Enhanced Inventory Management

Effective dock scheduling provides better visibility into inventory levels and shipment timelines. This enables businesses to maintain optimal stock levels, preventing both stockouts and overstocking. According to the Supply Chain Digital, proper inventory management can improve service levels by 15%, enhancing customer satisfaction.

Better Coordination and Communication

Dock scheduling facilitates improved coordination between different departments within a warehouse, such as receiving, storage, and shipping. By having a clear schedule, teams can align their activities, ensuring that shipments are processed efficiently and accurately. This coordination reduces the likelihood of errors and enhances the overall reliability of the logistics operations.

Implementing Dock Scheduling Systems

Choosing the Right Dock Scheduling Software

Selecting an appropriate dock scheduling software is crucial for effective implementation. The software should offer features like real-time tracking, automated scheduling, and integration with existing warehouse management systems (WMS). According to Forbes, businesses that invest in advanced scheduling software see a 25% improvement in on-time deliveries.

Training and Change Management

Successful implementation of dock scheduling systems requires comprehensive training and effective change management strategies. Employees should be well-versed in using the new systems to ensure smooth transitions and minimize disruptions. Providing ongoing support and addressing any resistance to change are essential for long-term success.

Integrating Dock Scheduling with Existing Systems

To maximize the benefits of dock scheduling, it should be seamlessly integrated with other critical systems such as WMS, transportation management systems (TMS), and enterprise resource planning (ERP) software. This integration ensures real-time data flow and enhances the overall efficiency of the supply chain operations.

Best Practices for Dock Scheduling

Advanced Planning and Scheduling

Advanced planning involves forecasting shipment volumes and scheduling dock usage accordingly. By anticipating peak periods and potential disruptions, businesses can allocate resources more effectively and avoid bottlenecks. Utilizing predictive analytics can enhance the accuracy of these forecasts.

Real-Time Monitoring and Adjustments

Continuous monitoring of dock activities allows for real-time adjustments to schedules, ensuring that any unforeseen issues are promptly addressed. Implementing real-time tracking tools can provide visibility into shipment statuses, enabling proactive management of delays and other challenges.

Prioritizing Shipments Based on Urgency

Not all shipments have the same level of urgency. Prioritizing shipments based on factors such as delivery deadlines, customer importance, and shipment size can help in efficient dock allocation. This prioritization ensures that critical shipments are handled promptly, enhancing customer satisfaction.

Technological Innovations in Dock Scheduling

Artificial Intelligence and Machine Learning

AI and machine learning technologies are revolutionizing dock scheduling by enabling predictive analytics and automated decision-making. These technologies can analyze vast amounts of data to optimize scheduling, predict delays, and suggest improvements. According to Gartner, AI-driven logistics solutions can enhance supply chain resilience by 30%.

Internet of Things (IoT) Integration

The integration of IoT devices in dock scheduling allows for real-time tracking of shipments and equipment. IoT-enabled sensors can monitor the condition and location of goods, providing valuable data for optimizing dock operations. This connectivity enhances accuracy and efficiency in handling shipments.

Automated Dock Management Systems

Automated dock management systems use robotics and automation to streamline loading and unloading processes. These systems reduce the reliance on manual labor, decrease turnaround times, and minimize the risk of human errors, leading to faster and more reliable dock operations.

Future Trends and Challenges in E-Commerce Logistics

Sustainability and Green Logistics

With increasing emphasis on environmental sustainability, e-commerce businesses are focusing on green logistics practices. Optimizing dock scheduling to reduce vehicle idle times and implementing eco-friendly transportation methods are key strategies. According to the United Nations, sustainable logistics practices can significantly reduce carbon emissions and environmental impact.

Last-Mile Delivery Innovations

The last mile of delivery remains one of the most challenging aspects of e-commerce logistics. Innovations such as drone deliveries, autonomous vehicles, and crowd-sourced delivery networks are being explored to enhance efficiency and reduce costs. These solutions aim to address the complexities and high costs associated with last-mile deliveries.

Resilience Against Supply Chain Disruptions

Building resilience against supply chain disruptions is a growing priority. Implementing robust dock scheduling systems that can adapt to unexpected changes, such as natural disasters or pandemics, is essential. Diversifying supply sources and enhancing real-time visibility are strategies that can help mitigate the impacts of disruptions.

Top Tools for Managing Your E-Commerce Warehouse with Dock Scheduling

- Warehouse Management Systems (WMS) - Comprehensive solutions for inventory tracking, order management, and dock scheduling integration. Examples include Oracle WMS and SAP Warehouse Management.

- Transportation Management Systems (TMS) - Tools for planning, executing, and optimizing transportation operations. Notable TMS platforms include IBM TMS and Blue Yonder TMS.

- Real-Time Tracking and Monitoring Tools - Solutions like TrackYourTruck and Geotab provide real-time visibility into shipment locations and statuses.

- Automated Supply Chain Solutions - Technologies such as robotic process automation (RPA) and machine learning algorithms that streamline warehouse operations. Examples include UiPath and IBM Watson.

- Collaborative Logistics Platforms - Platforms like Flexport and Project44 facilitate collaboration among different stakeholders in the supply chain, enhancing coordination and efficiency.

In conclusion, optimizing e-commerce logistics through effective dock scheduling is essential for the success of any online business. By implementing advanced dock scheduling systems, leveraging technology, and adhering to best practices, e-commerce companies can streamline their supply chains, reduce costs, and enhance customer satisfaction. Investing in the right tools and strategies ensures that businesses remain competitive in the dynamic e-commerce landscape.