Optimizing Inventory Logistics for Maximum Efficiency

Inventory management is an essential component of any successful business operation. Proper inventory logistics can help reduce inefficiencies, prevent stockouts, and ultimately lead to increased profitability. In this article, we will explore the importance of inventory logistics, the fundamentals of inventory management, the role of technology, and practical strategies to optimize your inventory logistics for maximum efficiency.

The Importance of Inventory Logistics for Business Success

Inventory logistics involves the planning and execution of the movement of goods, from sourcing raw materials to delivering finished products to customers. Efficient inventory logistics can help reduce lead times, prevent stockouts, and lower operational costs. Conversely, inefficient inventory management can lead to oversupply, increased carrying costs, and negatively impact the bottom line. Therefore, optimizing inventory logistics is crucial for enhancing business efficiency and achieving success.

One effective method to optimize inventory logistics is by implementing a Just-In-Time (JIT) inventory system. JIT is a lean manufacturing approach that aims to produce and deliver products precisely when needed to meet customer demand. This strategy can significantly reduce inventory holding costs, minimize waste, and improve overall efficiency. However, successful JIT implementation requires meticulous planning and strong coordination with suppliers and customers to ensure timely delivery of materials and products. Businesses must carefully evaluate the benefits and challenges before adopting a JIT system.

Understanding the Basics of Inventory Management

Inventory management involves balancing the supply and demand of products to ensure that the right products are available when customers need them. This includes determining the optimal inventory levels for each product, deciding when to reorder, and forecasting demand trends. Some common inventory management techniques include:

- Economic Order Quantity (EOQ) Model: Determines the optimal order quantity that minimizes total inventory costs.

- Just-In-Time (JIT) Methodology: Focuses on reducing in-process inventory and associated carrying costs.

- Safety Stock Calculations: Maintains a buffer stock to protect against demand variability and supply chain disruptions.

Effective inventory management also involves tracking inventory turnover rates and identifying slow-moving or obsolete products. By regularly reviewing inventory data, businesses can make informed decisions about which products to reorder and which to discontinue. Additionally, leveraging technology, such as inventory management software and barcode scanning systems, can automate inventory tracking and streamline the ordering process, saving time and reducing errors. Implementing robust inventory management practices leads to increased efficiency, improved customer satisfaction, and higher profits.

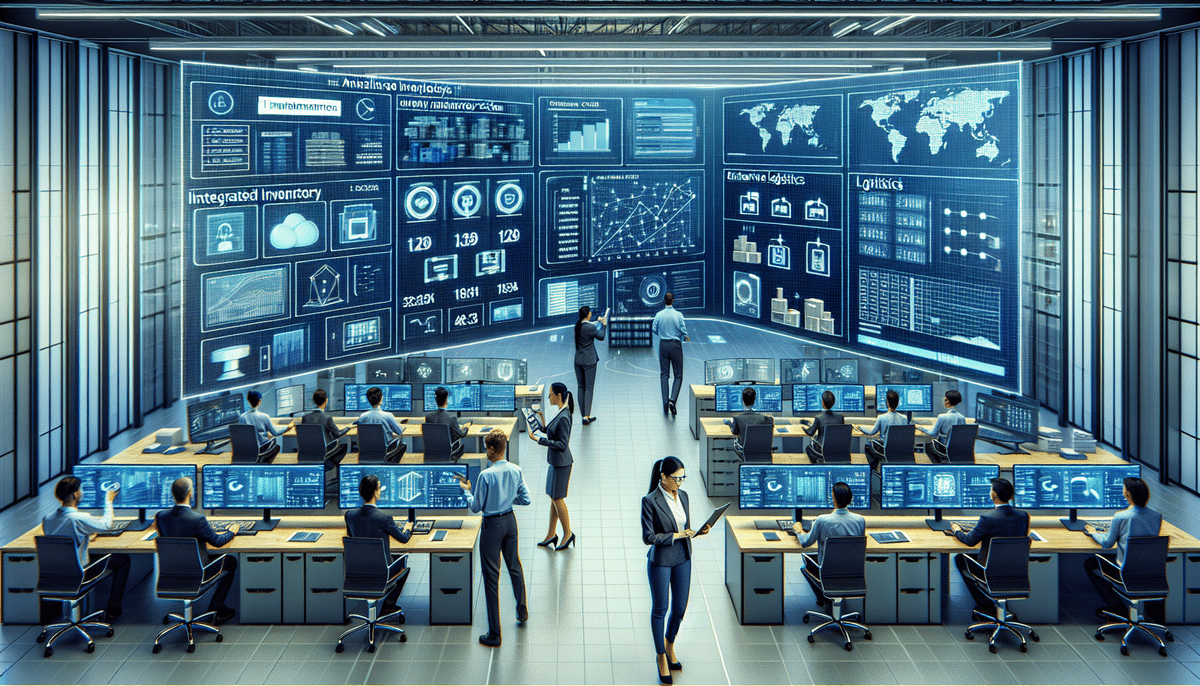

The Role of Technology in Inventory Management

Technology plays a pivotal role in optimizing inventory logistics. Advanced inventory management software can automate processes, track inventory in real-time, and provide valuable insights into demand and supply trends. Innovations such as Radio-Frequency Identification (RFID) and Automated Storage and Retrieval Systems (ASRS) enhance the accuracy and speed of inventory handling. Adopting the right technology can streamline your inventory logistics, reducing manual labor and minimizing errors.

Moreover, technology aids in reducing inventory costs through predictive analytics, which help businesses forecast demand and optimize inventory levels. This reduces the need for excess inventory and minimizes the risk of stockouts. Additionally, technology can identify slow-moving or obsolete inventory, enabling businesses to take proactive measures to prevent losses. According to a Investopedia report, companies leveraging advanced technologies in inventory management see a significant improvement in operational efficiency and customer satisfaction.

Practical Strategies to Optimize Inventory Logistics

Implementing Automated Inventory Systems

Automated inventory systems offer numerous advantages over manual methods. These systems can handle repetitive and labor-intensive tasks, reducing the time and effort required for inventory management. They improve accuracy, reduce errors, and minimize losses due to human error. Additionally, automated systems provide real-time data on inventory levels, demand, and sales, facilitating informed decision-making.

- Real-Time Tracking: Monitor inventory levels continuously to prevent stockouts and overstocking.

- Data-Driven Decisions: Use analytics to forecast demand and optimize inventory levels.

- Integration with Other Systems: Seamlessly connect with accounting, purchasing, and other business software to streamline operations.

By implementing automated inventory systems, businesses can achieve significant cost savings and improved productivity.

Analyzing Inventory Logistics for Continuous Improvement

A comprehensive analysis of inventory logistics is essential for identifying inefficiencies and areas needing improvement. Key approaches include:

- Physical Inventory Audits: Regularly count and verify inventory levels to identify discrepancies.

- Inventory Turnover Analysis: Calculate turnover ratios to evaluate inventory management efficiency.

- Monitoring Key Metrics: Track metrics such as reorder points, stockout rates, and carrying costs to identify improvement areas.

Additionally, analyzing lead times—the duration from order placement to fulfillment—can help identify delays and implement strategies to reduce them, thereby enhancing customer satisfaction and reducing stockout risks.

External factors like demand fluctuations, supply chain disruptions, and economic conditions also impact inventory logistics. By monitoring these factors and adapting inventory management strategies accordingly, businesses can maintain efficiency and profitability.

Key Metrics for Effective Inventory Management

Tracking essential metrics is vital for assessing and improving inventory management effectiveness. Some critical metrics include:

- Inventory Carrying Cost: The total cost of holding inventory, including storage, insurance, and opportunity costs.

- Inventory Turnover Rate: Measures how often inventory is sold and replaced over a specific period.

- Order-to-Delivery Lead Time: The time taken from placing an order to its delivery to the customer.

- Stockout Rate: The percentage of time a product is out of stock, indicating demand fulfillment efficiency.

- Demand Forecasting Accuracy: The precision of predicting future customer demand to optimize inventory levels.

By monitoring these metrics, businesses can identify potential issues, make informed decisions, and implement strategies to enhance inventory management.

Strategies for Reducing Inventory Costs and Waste

Reducing inventory costs and minimizing waste are crucial for improving profitability. Effective strategies include:

- Just-In-Time (JIT) Methodology: Producing and delivering products only as needed to reduce holding costs.

- Reducing Order Frequency: Consolidating orders to decrease transaction costs and improve negotiation leverage with suppliers.

- Collaborating with Suppliers: Working closely with suppliers to ensure timely delivery and reduce the need for excess inventory.

- Cycle Counting: Implementing regular inventory counts for small subsets of inventory to identify and rectify discrepancies promptly.

Additionally, utilizing inventory management software can streamline inventory processes, provide real-time tracking, automate ordering, and enhance demand forecasting, thereby reducing costs and waste.

Managing Seasonal and Fluctuating Demand

Seasonal and fluctuating demand poses significant challenges to inventory management. Effective management strategies include:

- Demand Forecasting: Predicting demand trends in advance to adjust inventory levels accordingly.

- Flexible Supply Chains: Developing adaptable supply chains that can respond swiftly to demand changes.

- Reliable Supplier Relationships: Establishing strong relationships with suppliers to ensure flexibility and timely deliveries.

- Safety Stock Levels: Maintaining buffer stock to protect against unexpected demand spikes.

Offering promotions and discounts during off-peak seasons can help reduce excess inventory and boost sales. Additionally, implementing JIT inventory systems minimizes waste and reduces costs associated with surplus inventory. Regular communication with customers and suppliers ensures alignment of demand and production schedules, preventing stockouts and delivery delays.

Investing in advanced inventory management technologies, such as automated ordering systems and predictive analytics, further enhances the ability to manage seasonal and fluctuating demand effectively.

Streamlining Your Supply Chain for Faster Delivery Times

Streamlining your supply chain is essential for reducing lead times and improving delivery efficiency. Strategies to achieve this include:

- Reducing the Number of Suppliers: Simplifying the supplier base to enhance coordination and reliability.

- Optimizing Transportation Routes: Utilizing route optimization software to minimize transit times and costs.

- Implementing Just-In-Time (JIT): Aligning inventory arrivals with production schedules to reduce storage needs.

- Adopting Automation Processes: Incorporating automated systems in warehousing and logistics to speed up operations.

By streamlining your supply chain, you enhance overall logistics efficiency, leading to faster delivery times and improved customer satisfaction. According to a Forbes Tech Council article, businesses that effectively streamline their supply chains experience up to a 20% increase in delivery speed, significantly boosting customer loyalty.

Case Studies: Real-Life Examples of Successful Inventory Logistics Optimization

Real-life case studies provide valuable insights into how businesses have successfully optimized their inventory logistics. By examining these examples, companies can gain practical ideas and strategies for implementing inventory optimization techniques. For instance:

- Company A: Implemented advanced inventory management software, resulting in a 30% reduction in stockouts and a 25% decrease in carrying costs.

- Company B: Adopted a Just-In-Time inventory system, which led to a 15% increase in operational efficiency and a 10% boost in profits.

- Company C: Utilized RFID technology to enhance inventory tracking accuracy, reducing inventory discrepancies by 40%.

These case studies demonstrate the tangible benefits of optimizing inventory logistics, including cost savings, improved efficiency, and enhanced customer satisfaction.

The Future of Inventory Management: Trends and Predictions

Inventory management is continually evolving with technological advancements and changing market dynamics. Key trends shaping the future include:

- Artificial Intelligence (AI) and Machine Learning: Leveraging AI for predictive analytics and automated decision-making to enhance inventory forecasting and management.

- Internet of Things (IoT): Utilizing IoT devices for real-time inventory tracking and data collection, enabling more accurate and timely inventory decisions.

- Blockchain Technology: Enhancing supply chain transparency and security through decentralized ledger systems.

- Cloud-Based Inventory Management: Adopting cloud solutions for scalable, accessible, and integrated inventory management systems.

Staying abreast of these trends allows businesses to adopt innovative inventory management practices, ensuring they remain competitive and responsive to market demands.

Choosing the Right Inventory Management Software for Your Business

Selecting the appropriate inventory management software is crucial for effective inventory logistics. Key factors to consider include:

- Features and Functionality: Ensure the software offers essential features such as real-time tracking, automated ordering, and comprehensive reporting capabilities.

- Cost: Evaluate the total cost of ownership, including licensing, implementation, and maintenance expenses.

- Ease of Use: The software should have an intuitive interface and be user-friendly to facilitate quick adoption by staff.

- Scalability: Choose software that can grow with your business, accommodating increasing inventory volumes and complexity.

- Integration Capabilities: Ensure the software can seamlessly integrate with existing systems like ERP, CRM, and accounting software.

Popular inventory management solutions include TradeGecko, NetStock, and Defofy, each offering unique features tailored to different business needs.

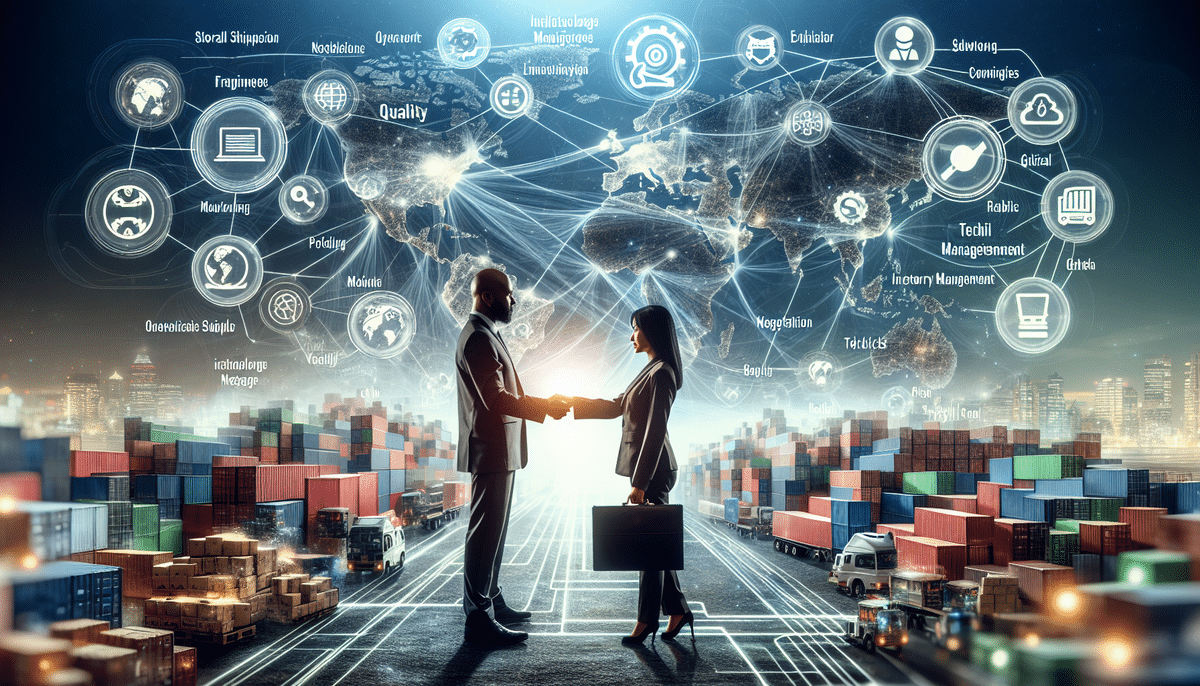

Overcoming Challenges in Global Supply Chain Management

Managing a global supply chain presents challenges such as language barriers, cultural differences, and varying regulatory requirements. To overcome these hurdles, businesses can adopt the following strategies:

- Develop a Robust Supply Chain Strategy: Create a comprehensive plan that addresses potential risks and outlines contingency measures.

- Establish Reliable Supplier Relationships: Build strong partnerships with suppliers to ensure reliability and facilitate smooth communication.

- Utilize Technology for Streamlined Logistics: Implement supply chain management software to enhance visibility, coordination, and efficiency across the supply chain.

- Invest in Cross-Cultural Training: Equip your team with the skills to navigate cultural differences and communicate effectively with international partners.

By addressing these challenges proactively, businesses can effectively manage their global supply chains, ensuring consistency, reliability, and efficiency in their inventory logistics.

Maintaining Accurate Inventory Records and Preventing Stockouts

Accurate inventory records are fundamental to efficient inventory logistics. To maintain precision and prevent stockouts, consider the following tips:

- Implement Cycle Counting: Regularly count a portion of inventory items to identify and correct discrepancies promptly.

- Utilize Inventory Management Software: Leverage software solutions to automate inventory tracking, reducing the likelihood of human error.

- Create a Backup Inventory System: Establish contingency plans to maintain inventory accuracy in case of system failures.

- Train Staff Effectively: Ensure that all team members are well-trained in inventory management procedures and best practices.

By adopting these practices, businesses can enhance the accuracy of their inventory records, minimize the risk of stockouts, and ensure a smooth and efficient inventory management process.

Conclusion

Optimizing inventory logistics is critical for achieving operational efficiency and business success. By understanding the fundamentals of inventory management, leveraging advanced technology, and implementing practical strategies, businesses can enhance efficiency, reduce costs, and improve customer satisfaction. Staying informed about the latest trends and best practices ensures that businesses are well-positioned to navigate the evolving landscape of inventory management, securing a competitive edge both now and in the future.