Optimizing Order Picking for E-Commerce Logistics

Order picking is a crucial component of the e-commerce logistics process. It involves selecting and retrieving items from warehouse shelves to fulfill customer orders. Ensuring efficient and accurate order picking is essential for maintaining customer satisfaction, reducing labor costs, and meeting delivery timelines. In this article, we will delve into the key aspects of optimizing order picking for e-commerce logistics.

Understanding the Importance of Order Picking in E-Commerce Logistics

Order picking is a complex and time-consuming process that entails selecting, collecting, and organizing items from warehouse shelves to fulfill customer orders. It plays a pivotal role in e-commerce logistics, significantly impacting customer experience, company reputation, and profitability. According to a McKinsey & Company study, efficient order picking can reduce fulfillment costs by up to 25%, directly enhancing profitability.

The quality of order picking determines whether customers receive their orders on time and in good condition, influencing their decision to return to the company's services. Moreover, efficient and accurate order picking helps reduce overall operational costs, improves inventory management, and increases profitability.

One of the primary challenges in e-commerce order picking is the high volume of orders that need to be fulfilled within short periods. This necessitates a well-organized and optimized warehouse layout, where items are arranged logically and are easily accessible. Implementing technology such as barcode scanners and automated picking systems can enhance the speed and accuracy of order picking, minimizing errors and delays. A Forbes report highlights that companies investing in advanced order picking technologies see a significant increase in fulfillment efficiency.

Common Challenges Faced in Order Picking for E-Commerce Logistics

E-commerce logistics presents several challenges that can complicate the order picking process. These include:

- High volumes of orders

- Constantly changing inventory

- Varying demand patterns

- Tight delivery schedules

- Order accuracy issues

- Misplaced items in the warehouse

- Staff fatigue and inadequate training

These challenges can lead to a slow and inefficient order picking process, inaccurate order fulfillment, and increased operating costs.

One significant challenge is the need for real-time inventory management. With constantly changing inventory, it's difficult to keep track of stock levels and ensure that the right products are available for order fulfillment. Implementing a robust inventory management system that tracks inventory levels in real-time provides accurate information to the order picking team, thereby enhancing efficiency.

Another challenge is ensuring efficient and accurate order picking. A well-organized warehouse layout with clear labeling and signage helps staff quickly locate items. Additionally, leveraging technology such as barcode scanners and automated picking systems can improve accuracy and speed up the order picking process.

Efficient Order Picking Strategies for E-Commerce Logistics

To optimize order picking for e-commerce logistics, several strategies can be employed:

- Wave Picking: Groups orders by product type or location to reduce travel time and minimize congestion.

- Batch Picking: Involves picking items for multiple orders simultaneously, streamlining the process and reducing the distance pickers travel.

- Zone Picking: Divides the warehouse into zones, allowing pickers to focus on specific areas and optimize the picking process.

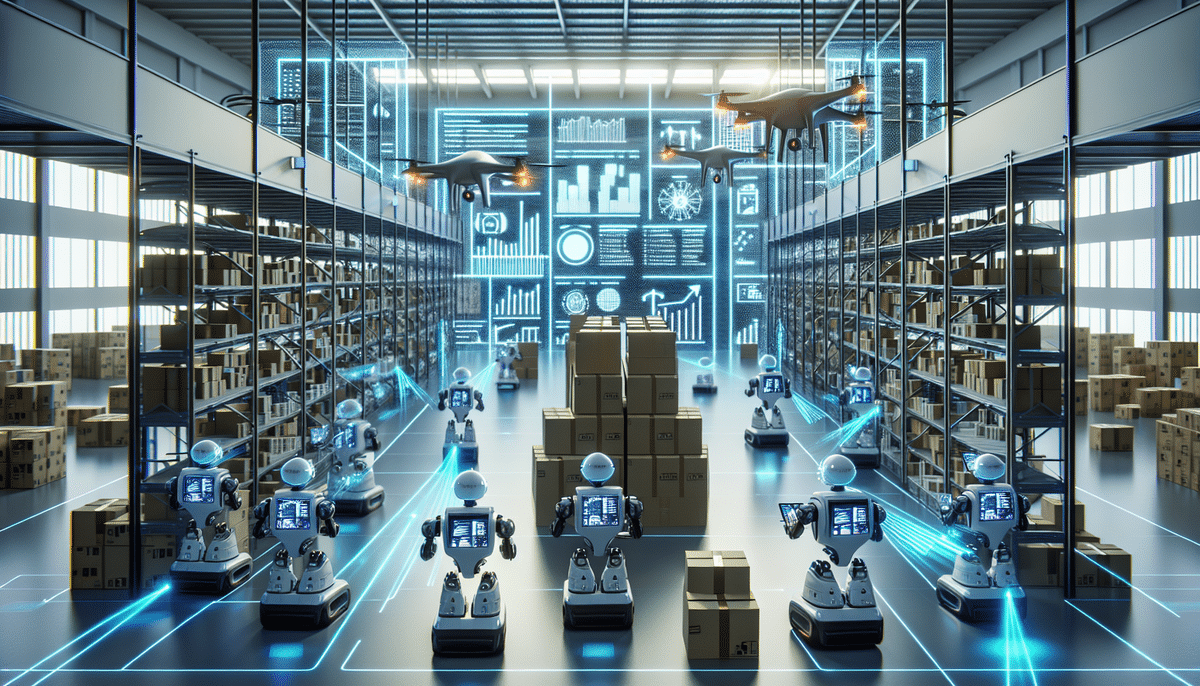

Automation in Order Picking

In addition to these strategies, automation plays a pivotal role in efficient order picking. Automated systems such as conveyor belts, robots, and Automated Storage and Retrieval Systems (AS/RS) can significantly reduce the time and effort required for order picking. These systems enhance accuracy and lower the risk of errors, leading to higher customer satisfaction and fewer returns.

Warehouse Layout Optimization

The layout and design of the warehouse are critical when implementing order picking strategies. A well-designed warehouse with clear signage, efficient traffic flow, and optimized storage locations can greatly improve the speed and accuracy of order picking. Regular analysis and optimization of the warehouse layout help identify areas for improvement, ensuring that the order picking process remains efficient and effective over time.

Automation Solutions for Order Picking in E-Commerce Logistics

To enhance the speed and accuracy of order picking in e-commerce logistics, companies can invest in automation solutions such as Automated Storage and Retrieval Systems (ASRS) or Autonomous Mobile Robots (AMR). ASRS utilizes robotic systems to store and retrieve items from warehouse shelves, while AMRs can navigate warehouses independently to pick items for orders. These automation solutions can reduce warehouse congestion, minimize human error, and accelerate the order picking process, resulting in lower logistics costs and improved customer satisfaction.

However, implementing automation solutions requires significant upfront investment and may necessitate changes to existing warehouse infrastructure. Additionally, companies must ensure that employees are trained to work alongside these automated systems and that the systems are adequately maintained to prevent downtime or malfunctions. Despite these challenges, the long-term benefits of automation solutions for order picking in e-commerce logistics make them a worthwhile investment for companies aiming to enhance their operations and stay competitive in the market.

Improving Accuracy and Speed in Order Picking for E-Commerce Logistics

Enhancing speed and accuracy in the order picking process can be achieved through several methods:

- Barcode Scanning: Scanning items before picking verifies their accuracy and location.

- Picking Technologies: Systems like Pick-to-Light or Voice-Activated Picking provide real-time feedback to pickers, ensuring error-free picking.

- Staff Training and Incentives: Providing adequate training and incentivizing staff can improve efficiency and accuracy in the order picking process.

Optimizing the warehouse layout is another effective way to enhance accuracy and speed. Grouping frequently ordered items together and placing them closer to the packing area reduces the time taken to pick items and increases the number of orders that can be fulfilled daily. Additionally, using automated storage and retrieval systems can decrease the time required to locate items, thereby improving the overall efficiency of the order picking process.

Training and Development of Staff for Effective Order Picking in E-Commerce Logistics

Staff training and development are crucial for ensuring effective and efficient order picking in e-commerce logistics. Employees should receive comprehensive training in warehouse operations, inventory management, and order picking procedures. Continuous training and coaching help staff improve their performance, reduce pick errors, and increase productivity.

Incentivizing staff with bonuses or recognition for meeting performance metrics can boost morale and enhance overall efficiency. Additionally, with the increasing use of automation and robotics in e-commerce logistics, employees need training in operating automated picking systems, using handheld devices for inventory management, and troubleshooting common technological issues.

Cross-training employees in different areas of the warehouse can also improve overall efficiency. By having employees trained in multiple areas, they can be utilized flexibly across the warehouse as needed, reducing the need for additional staff and enhancing operational flexibility. This approach also leads to increased job satisfaction and a sense of fulfillment for employees who acquire diverse skills.

Choosing the Right Technology and Equipment for Order Picking in E-Commerce Logistics

Selecting the appropriate technology and equipment for order picking in e-commerce logistics is essential for optimizing the process. Companies should evaluate their order volumes, product types, and warehouse layout to determine the best technologies and equipment to implement. Technologies such as handheld scanners, Pick-to-Light, and Voice-Activated Picking can enhance the accuracy and efficiency of the order picking process. Meanwhile, equipment like conveyors, pallet jacks, and forklifts can streamline the movement of items within the warehouse, further optimizing the order picking process.

Another critical factor to consider is the level of automation required. Automated systems such as Automated Storage and Retrieval Systems (ASRS) and Automated Guided Vehicles (AGVs) can significantly reduce the need for manual labor and increase the speed and accuracy of order picking. However, these systems often entail substantial implementation costs and may require significant changes to the warehouse layout and infrastructure.

It is also important to consider the training and support necessary for the chosen technology and equipment. Employees must be adequately trained to use the equipment and technology effectively and efficiently. Additionally, companies should establish a support system to address any issues or malfunctions that may arise with the technology and equipment.

Evaluating the Performance Metrics of Order Picking in E-Commerce Logistics

To track and evaluate the efficiency of order picking in e-commerce logistics, companies should monitor several key performance metrics:

- Order Accuracy Rates: Measures the percentage of orders picked correctly without errors.

- Order Cycle Times: The total time taken from order receipt to order fulfillment.

- Pick Rates: The number of items picked per hour or day.

- Error Rates: The frequency of mistakes occurring during the picking process.

By tracking these metrics, managers can identify areas for improvement in the order picking process, implement necessary adjustments, and evaluate the impact of optimization efforts. Additionally, benchmarking against industry standards and competitors can provide valuable insights into the performance of the order picking process.

Measuring the ROI of Optimizing Order Picking for E-Commerce Logistics

Measuring the return on investment (ROI) of optimizing order picking is essential to justify investments in technology, equipment, and process improvements. ROI can be measured by calculating the cost savings resulting from increased efficiency, reduced labor costs, and improved accuracy. For instance, a Deloitte report indicates that automation in order picking can lead to an ROI increase of up to 35% within two years.

Additionally, ROI can be assessed by evaluating the impact on customer satisfaction, repeat business, and overall profitability. Higher accuracy and faster order fulfillment lead to increased customer satisfaction, fostering repeat business and enhancing the company's reputation. By measuring ROI, managers can make data-driven decisions and prioritize optimization efforts that provide the highest returns.

Best Practices for Streamlining Order Picking Processes in E-Commerce Logistics

Streamlining the order picking process in e-commerce logistics requires a comprehensive approach that integrates people, processes, and technology. Some best practices include:

- Optimizing Warehouse Layout: Design the warehouse to minimize travel time and enhance accessibility to frequently picked items.

- Employing Efficient Picking Strategies: Implement strategies like wave picking, batch picking, and zone picking to enhance efficiency.

- Automating Where Possible: Utilize automation technologies to reduce manual labor and increase accuracy.

- Providing Adequate Training and Incentives: Ensure staff are well-trained and motivated to perform efficiently.

- Tracking and Evaluating Performance Metrics: Continuously monitor key metrics to identify areas for improvement.

By adhering to these best practices, companies can improve the efficiency and accuracy of their order picking processes, enhance customer satisfaction, and increase profitability.

Future Trends and Innovations in Order Picking for E-Commerce Logistics

The future of order picking in e-commerce logistics is set to embrace more advanced automation and robotics technologies. Emerging trends include:

- Drones for Last-Mile Delivery: Drones could become a common method for last-mile item delivery, reducing delivery times and costs.

- Robotics in Warehousing: Increased use of robots for order picking and item transport within warehouses.

- Artificial Intelligence (AI) and Machine Learning (ML): These technologies could enhance the accuracy and speed of the order picking process by predicting demand patterns and optimizing picking routes.

- Sustainability Initiatives: Focus on reducing carbon footprints through green initiatives such as warehouse solar panels and electric vehicle fleets.

According to a Gartner report, the integration of AI and robotics in order picking is expected to increase warehouse efficiency by 40% by 2025. Embracing these innovations will be essential for companies to stay competitive and meet the evolving demands of the e-commerce market.

Conclusion

Optimizing order picking for e-commerce logistics is a critical process that impacts customer satisfaction, operating costs, and overall profitability. By understanding the importance of order picking, addressing common challenges, employing efficient picking strategies, utilizing technology and automation solutions, and continuously tracking and evaluating performance metrics, companies can streamline the order picking process and enhance their competitive advantage. With future trends such as automation and sustainability on the horizon, investing in optimizing the order picking process is essential for e-commerce companies aiming to thrive in a dynamic and demanding market.