Optimizing Supply Chain Efficiency with CBM (Cubic Meter) Measurement

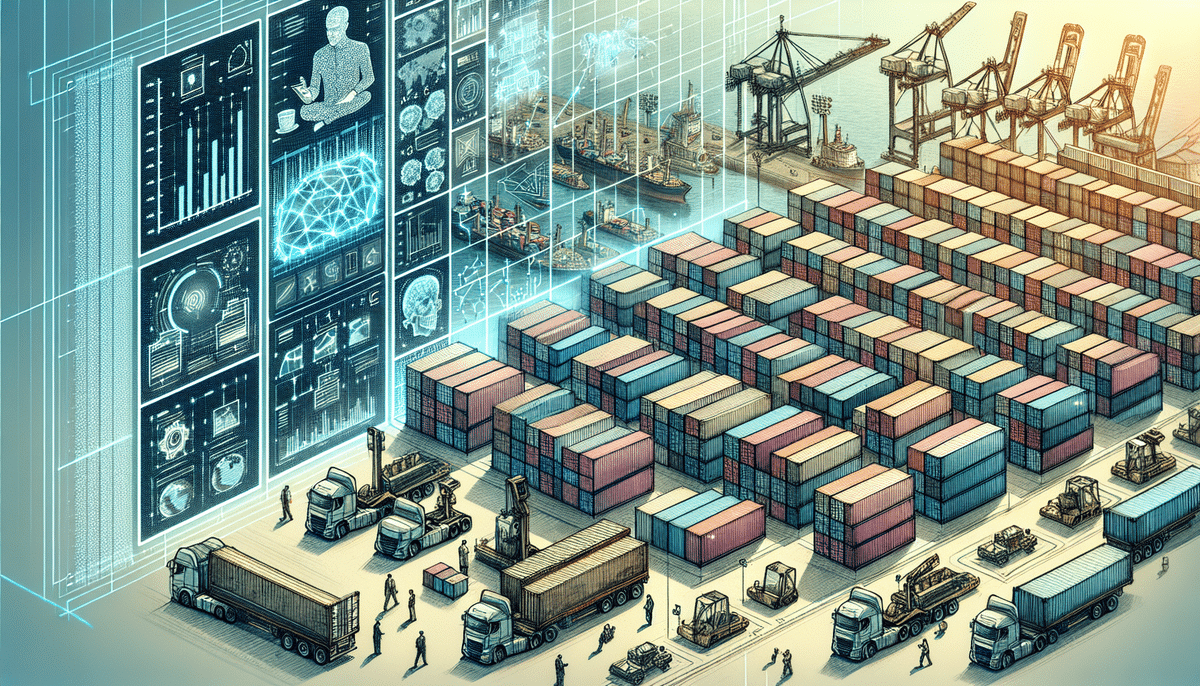

In today's competitive business landscape, effective supply chain management is paramount for success. The supply chain encompasses the intricate network of processes and activities that transport products from manufacturers to end consumers. Even a minor disruption within this chain can lead to significant setbacks, including elevated costs and diminished customer satisfaction. Therefore, optimizing the entire supply chain is essential for maintaining efficiency and competitiveness. One increasingly popular approach to achieving this optimization is through the use of CBM (Cubic Meter) measurement. This article delves into what CBM is, its significance in supply chain management, methods for calculating CBM, and the benefits it offers in streamlining supply chain operations.

What is CBM and How It Helps Optimize Supply Chain Efficiency

Cubic Meter (CBM) measurement is a volumetric unit used to determine the space a product occupies. Given that products vary in shape and size, accurately estimating their spatial requirements can be challenging. By employing CBM measurements, companies can precisely determine the volume each product will occupy during transit and storage.

Accurate CBM measurements are instrumental in enhancing supply chain efficiency. Understanding the spatial footprint of products enables logistics managers to:

- Plan Loading and Unloading: Optimize how products are loaded onto transportation vehicles, maximizing space utilization.

- Choose Appropriate Containers: Select the right type and size of shipping containers and trucks, reducing unused space.

- Optimize Storage Facilities: Arrange storage spaces efficiently to accommodate product volumes effectively.

Efficient supply chain management, underpinned by precise CBM measurements, helps businesses minimize costs and boost customer satisfaction.

Additionally, CBM measurements aid in selecting the most cost-effective mode of transportation. For example, products with high CBM might be more economically transported via sea freight rather than air freight due to lower costs associated with bulk shipments. Conversely, products with low CBM may benefit from the speed and efficiency of air freight.

According to a report by Supply Chain 2025, adopting CBM measurements can lead to a 15-20% reduction in shipping costs.

The Importance of Accurate CBM Measurement for Supply Chain Management

Precision in CBM measurement is critical for optimizing supply chain efficiency. Inaccurate measurements can result in overestimating or underestimating the required space, leading to increased shipping and storage expenses, delivery delays, or even product damage due to improper handling.

Accurate CBM measurement extends beyond merely calculating product dimensions. It encompasses accounting for packaging materials such as boxes, crates, and pallets. Failing to include the volume occupied by these materials can lead to significant discrepancies. Therefore, precise measurements must consider both the product and its packaging to ensure accuracy.

Moreover, accurate CBM measurements contribute to reducing the supply chain's carbon footprint. By optimizing space utilization for shipping and storage, the number of required trips decreases, resulting in lower fuel consumption and reduced emissions. This not only benefits the environment but also lowers transportation costs for businesses.

For further reading on the environmental impact of supply chain optimization, refer to the EPA's Sustainable Materials Management report.

How to Calculate CBM for Your Supply Chain Operations

The CBM calculation process is straightforward. To determine CBM, measure the product's dimensions and multiply them together using the formula:

Length × Width × Height = CBM

All measurements should be in meters to ensure the CBM value is in cubic meters.

To achieve accurate CBM measurements, it's essential to include the volume of packaging materials. This can be accomplished by:

- Measuring the dimensions of packaging materials and incorporating them into the CBM calculation.

- Utilizing pre-set volume tables tailored for standard packaging sizes.

It's important to recognize that CBM is just one factor in supply chain planning. Other considerations, such as weight, fragility, and transportation mode, play crucial roles. For instance, air freight charges are typically based on both weight and volume, making it essential to consider both factors when estimating shipping costs.

For a comprehensive guide on CBM and its role in logistics, visit ShipScience's CBM Calculation Guide.

Benefits of Using CBM Measurement for Supply Chain Optimization

Implementing CBM measurement in supply chain operations offers numerous advantages:

- Cost Reduction: Enhanced space utilization leads to lower shipping and storage costs.

- Improved Delivery Times: Efficient loading and unloading processes reduce transit times.

- Minimized Product Damage: Proper space allocation decreases the risk of damage during transit and storage.

- Better Inventory Management: Accurate space requirements prevent overstocking or understocking, safeguarding financial health.

- Environmental Benefits: Optimized transportation reduces fuel consumption and emissions, contributing to a smaller carbon footprint.

- Identification of Supply Chain Inefficiencies: Analyzing CBM data highlights bottlenecks and areas needing improvement.

Studies have shown that businesses utilizing CBM measurements can achieve up to a 25% improvement in supply chain efficiency (Logistics Management).

Real-Life Examples of Companies that Have Optimized Their Supply Chain Efficiency with CBM Measurement

Several leading companies have successfully integrated CBM measurement into their supply chain operations:

- Walmart: By implementing CBM measurements across its global supply chain, Walmart has significantly reduced logistics costs and enhanced operational efficiency.

- Nestlé: Nestlé has utilized CBM measurements to optimize the packaging and transportation of its coffee pods, resulting in improved efficiency.

- Amazon: The e-commerce giant employs CBM measurements in its fulfillment centers to enhance inventory management and reduce shipping times, enabling faster and more reliable deliveries.

- Coca-Cola: Coca-Cola has integrated CBM measurement into its supply chain to optimize production and distribution processes, thereby reducing downtime and maintenance costs.

These implementations demonstrate the tangible benefits of adopting CBM measurements, including cost savings, increased efficiency, and enhanced customer satisfaction.

The Role of Technology in Improving CBM Measurement Accuracy and Efficiency

Technological advancements play a pivotal role in enhancing the accuracy and efficiency of CBM measurements. Modern dimensioning systems enable logistics managers to obtain precise product measurements swiftly. Technologies such as RFID and barcode systems facilitate rapid product tracking throughout the supply chain, ensuring accurate CBM data collection.

Automation through robots and automated systems allows for optimal sorting and packing of products based on their CBM measurements, further increasing operational efficiency.

Artificial Intelligence (AI) is revolutionizing CBM measurement by analyzing vast datasets to provide actionable insights. AI-powered systems can identify the most efficient transportation routes based on CBM data, optimizing logistics operations.

Moreover, cloud-based systems offer real-time tracking of products, enhancing visibility and reducing the risk of lost or damaged items. These integrations not only improve CBM measurement accuracy but also streamline overall supply chain management.

For more on how technology enhances CBM measurements, explore Tech Logistics' Insights on CBM Technology.

How to Implement CBM Measurement in Your Existing Supply Chain Processes

Integrating CBM measurement into existing supply chain processes involves several key steps:

- Select Appropriate Systems: Invest in dimension weight scales and dimension scanning technology to facilitate accurate CBM measurements.

- Establish Standard Operating Procedures: Develop and implement procedures for consistent measurement and tracking of product volumes.

- Train Logistics Staff: Educate staff on the importance of precise CBM measurements and the correct methods for conducting them.

- Implement Data Management Systems: Utilize high-quality data management solutions to analyze and interpret CBM data effectively.

Successful implementation of CBM measurement can lead to substantial cost savings and operational efficiencies. By accurately gauging product volumes, businesses can optimize transportation and storage space, reducing the need for additional resources and lowering overall costs.

Furthermore, CBM measurement aids in identifying and addressing supply chain issues such as overpacking or space underutilization, allowing for proactive improvements.

For a step-by-step implementation guide, refer to ShipScience's CBM Implementation Guide.

Tips for Managing and Analyzing CBM Data to Continuously Improve Supply Chain Efficiency

Collecting CBM data is only the first step; effective management and analysis are crucial for ongoing supply chain improvements. Here are some strategies:

- Data Aggregation: Utilize systems that consolidate CBM data to provide a comprehensive, real-time view of the supply chain.

- Identify Patterns and Gaps: Analyze CBM data to uncover trends, inefficiencies, and opportunities for optimization.

- Develop Action Plans: Create and implement strategies based on data insights to enhance supply chain performance continuously.

- Ensure Data Accuracy: Implement quality control measures and regularly validate CBM data to maintain reliability.

- Engage Stakeholders: Involve all relevant parties in data management and analysis to ensure alignment and collective goal attainment.

By effectively managing CBM data, businesses can leverage insights to refine their supply chain operations, leading to sustained efficiency and a competitive edge in the market.

Learn more about supply chain data management at SCM World's Guide to CBM Data Management.

Future Trends in CBM Measurement and Its Impact on the Future of Supply Chain Management

The future of CBM measurement is poised for significant advancements, driven by technological innovations. Emerging technologies are enhancing the accuracy of CBM measurements, leading to greater efficiency and cost savings in supply chain management.

The integration of the Internet of Things (IoT) and Artificial Intelligence (AI) will further refine CBM measurement accuracy and operational efficiency, minimizing the dependence on manual input and reducing human error.

Looking ahead, the adoption of blockchain technology in CBM measurement offers promising benefits. Blockchain can provide a secure and transparent platform for tracking and verifying CBM measurements throughout the supply chain, mitigating risks of fraud and data inaccuracies.

Additionally, blockchain enables the creation of smart contracts that automatically execute actions based on CBM measurements, such as initiating shipments or adjusting inventory levels. This automation can streamline supply chain processes, enhancing reliability and responsiveness.

As blockchain technology continues to evolve, it holds the potential to revolutionize CBM measurement and supply chain management, fostering more reliable and efficient operations.

In summary, CBM measurement is an indispensable tool for supply chain optimization, offering numerous benefits including cost reduction, improved delivery times, and minimized product damage. By integrating CBM into supply chain operations and leveraging advanced technologies for data management, businesses can enhance efficiency, reduce costs, and secure a competitive advantage in the marketplace.

Conclusion

Optimizing supply chain efficiency through CBM measurement is a strategic approach that offers substantial benefits, from cost savings to enhanced operational performance. By accurately measuring product volumes and integrating advanced technologies, businesses can streamline their supply chain processes, reduce environmental impact, and improve overall competitiveness.

As technology continues to advance, the role of CBM measurement will become increasingly significant, driving further innovations and efficiencies in supply chain management. Embracing these advancements ensures that businesses remain agile, cost-effective, and capable of meeting the evolving demands of the market.