Optimizing Supply Chain Operations for Maximum Efficiency

In today's fast-paced business environment, optimizing supply chain operations is essential for achieving maximum efficiency. Every aspect of the supply chain process, from procurement to delivery, must be streamlined to ensure that the entire operation runs smoothly. This article explores various strategies and methods for optimizing your supply chain and measuring the success of your efforts.

Understanding the Importance of Supply Chain Optimization

Supply chain optimization involves maximizing the efficiency of the supply chain network, which comprises suppliers, manufacturers, retailers, and customers. The primary goal is to enhance the speed, quality, and cost-effectiveness of operations. An optimized supply chain enables businesses to handle demand fluctuations efficiently, reduce expenses, and improve customer satisfaction. Moreover, streamlined processes help reduce waste, increase profits, and establish a competitive advantage in the market.

Benefits of Supply Chain Optimization

- Increased Visibility and Transparency: Enhanced visibility allows businesses to track inventory levels, monitor supplier performance, and identify bottlenecks or delays.

- Cost Reduction: Streamlined operations and reduced waste lead to significant cost savings.

- Improved Customer Satisfaction: Efficient supply chains ensure timely deliveries and consistent product quality.

- Agility and Resilience: Optimized supply chains can adapt quickly to market changes and disruptions.

According to a McKinsey report, companies with optimized supply chains experience up to 20% higher operating margins.

Identifying Key Areas for Supply Chain Efficiency Improvements

The first step in optimizing your supply chain is to identify areas that require improvement. Conducting a comprehensive supply chain analysis helps assess current processes and pinpoint areas that consume excessive resources, create bottlenecks, or cause delays. Key areas to consider include:

- Raw materials handling

- Inventory management

- Transportation and logistics

- Procurement and sourcing

Utilizing Technology for Efficiency

Implementing technology solutions such as automation, data analytics, and artificial intelligence can streamline processes, reduce errors, and improve overall efficiency. Technologies like AI in supply chain management can offer predictive analytics for better demand forecasting and inventory management.

Moreover, integrating advanced systems ensures that new technologies seamlessly blend with existing processes, enhancing overall operational efficiency.

Human Factors in Supply Chain Optimization

Beyond technology, the human element plays a critical role. Investing in employee training and development boosts productivity, reduces turnover, and equips the workforce with necessary skills. Cultivating a culture of continuous improvement and encouraging employee feedback can drive innovation and identify further improvement areas.

Implementing Technology Solutions for Supply Chain Optimization

The integration of technology in supply chain management is increasingly vital. Technologies such as advanced analytics, transportation management systems (TMS), and warehouse management systems (WMS) enable businesses to make data-driven decisions, reduce costs, and enhance productivity.

Advanced Analytics

Using data analytics, businesses can gain insights into inventory levels, cost-to-serve, and demand forecasts. Gartner states that advanced analytics can improve supply chain efficiency by up to 15%.

Prescriptive analytics can recommend optimized solutions for complex supply chain challenges, enhancing decision-making processes.

Real-Time Tracking and Communication

Implementing technologies like RFID enables real-time inventory tracking, preventing stock-outs and overstocking. Enhanced communication tools ensure that customers receive accurate information about their orders, including delivery times and potential delays, thereby improving customer satisfaction.

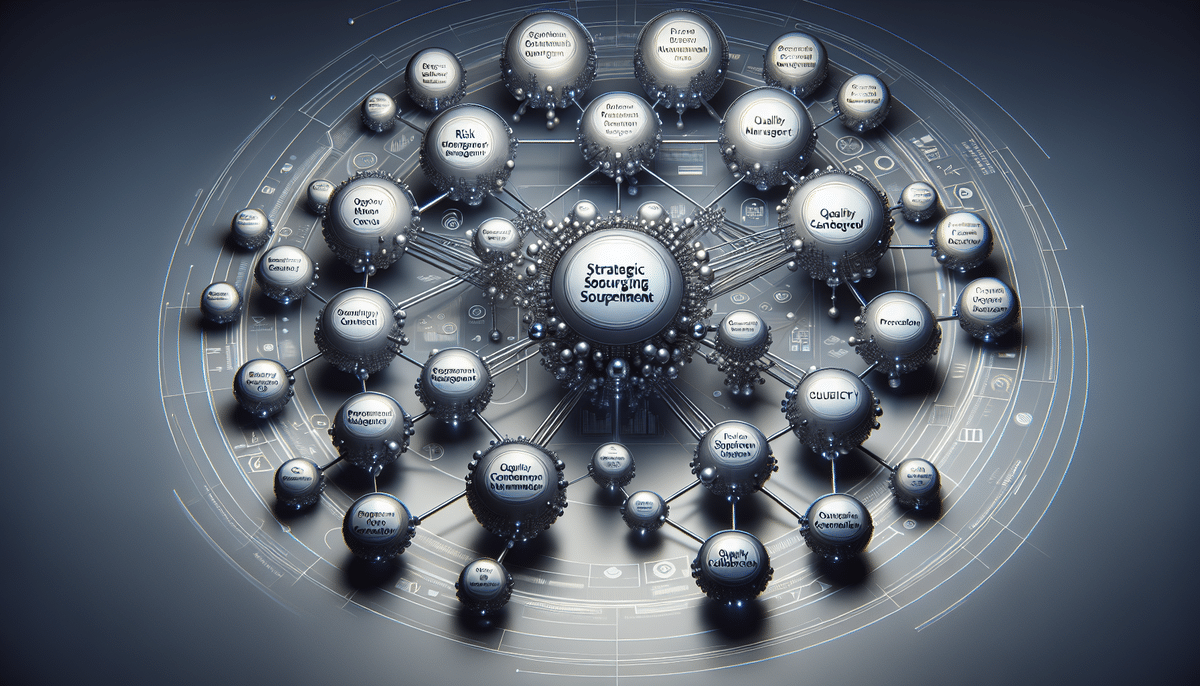

Building Stronger Supplier Relationships

Strong relationships with suppliers are crucial for minimizing supply chain disruptions. Reliable suppliers can offer lower prices, improve product quality, and ensure consistency, leading to a more efficient supply chain.

Establishing Trust and Transparency

Building trust through transparent communication and data sharing is fundamental. Harvard Business Review emphasizes that trust and openness enhance collaboration and performance.

Collaborative Innovation

Working together with suppliers on product development and innovation can result in new, improved products that benefit both parties. This collaboration fosters a more integrated and responsive supply chain.

Supplier Performance Metrics

Implementing metrics to track supplier performance helps identify strengths and areas for improvement. Regular performance reviews and feedback ensure continuous improvement and reliability within the supply chain.

Lean Manufacturing and Sustainable Practices

Adopting lean manufacturing principles minimizes waste and maximizes customer value. By reducing waste, businesses can save time and money while enhancing efficiency.

Implementing Lean Principles

Lean principles focus on identifying value, simplifying tasks, eliminating waste, and continuously improving processes. This approach leads to higher quality products, reduced defects, and faster lead times.

Sustainable Supply Chain Practices

Integrating sustainable practices, such as using alternative energy sources and reducing waste, helps lower the carbon footprint and enhances the supply chain's efficiency. Sustainable supply chains not only reduce costs but also improve customer relations and meet regulatory requirements.

According to the Renewable Energy World, sustainable supply chains can lead to up to a 10% reduction in operational costs.

Measuring Success and Overcoming Challenges

Measuring the success of supply chain optimization efforts is crucial to understanding their effectiveness and identifying areas for further improvement. Key performance indicators (KPIs) include:

- Customer satisfaction

- Inventory turnover

- Lead times

- Total landed cost

Common Challenges and Solutions

Optimizing supply chains comes with challenges such as managing relationships, mitigating cyber threats, and maintaining product quality. Overcoming these requires a combination of technical expertise, strategic planning, and critical thinking. Developing contingency plans and risk management strategies helps businesses navigate these challenges effectively.

For instance, implementing robust cybersecurity measures is essential to protect supply chain data and prevent disruptions caused by cyber threats.

Moreover, maintaining high product quality throughout the supply chain ensures customer satisfaction and reduces returns or complaints.

Leveraging Data Analytics

Data analytics is pivotal in making informed decisions and improving supply chain performance. By analyzing data trends, businesses can forecast demand, optimize inventory levels, and enhance overall supply chain planning.

Advanced data analytics tools can provide predictive insights, allowing companies to proactively address potential issues before they escalate.

Training Your Team for Successful Supply Chain Management

Successful supply chain optimization requires a knowledgeable and skilled workforce. Investing in employee training and development ensures that team members understand supply chain processes and can effectively manage their roles.

Providing access to the latest best practices and technologies empowers employees to contribute to the continuous improvement of supply chain operations.

Conclusion

Optimizing supply chain operations is essential for achieving maximum efficiency. By streamlining processes, leveraging technology, building stronger supplier relationships, and investing in employee training, businesses can reduce costs and enhance operational efficiency. Regularly measuring the effectiveness of these efforts allows for continuous refinement, leading to a sustainable, efficient, and cost-effective supply chain.