Introduction to Walmart's Supply Chain

As one of the largest retailers in the world, Walmart's supply chain is critical to its success. Managing the supply chain of such a vast organization comes with significant challenges, and optimizing it for maximum efficiency is no easy feat. This article explores the current state of Walmart's supply chain operations, examines the challenges it faces, and provides recommendations for optimizing its supply chain for maximum efficiency.

Current State of Walmart's Supply Chain Operations

Walmart's supply chain encompasses everything from vendor management to inventory control, logistics, and transportation. With over 11,600 stores worldwide and a product catalogue exceeding 100 million items, the company's supply chain plays a pivotal role in ensuring it can meet customer demands while maintaining affordable prices.

One of the key strategies that Walmart employs in its supply chain is the use of advanced technology. The company has heavily invested in automated warehouses, robotics, and data analytics. According to Forbes, these technologies have enabled Walmart to optimize inventory levels, reduce transportation costs, and improve delivery times, ultimately enhancing the customer experience.

Challenges in Managing Walmart's Supply Chain

Walmart faces several challenges in managing its complex supply chain:

- Coordination Across a Vast Network: Managing relationships with over 100,000 suppliers requires robust communication and coordination to ensure timely delivery and quality standards.

- Inventory Management: Balancing high product availability with minimizing excess stock is critical to reducing costs and preventing waste.

- Transportation Delays and Disruptions: Global events, such as the COVID-19 pandemic, have highlighted the vulnerability of supply chains to disruptions, impacting product availability and increasing costs.

- Ethical and Sustainable Sourcing: Ensuring that products are sourced responsibly requires stringent supplier audits and compliance with environmental and social standards.

- International Trade and Customs Regulations: Navigating the complexities of global trade laws and customs can be time-consuming and costly, especially with the increasing frequency of trade tensions.

Addressing these challenges requires continuous innovation and adaptation to the evolving global market landscape.

Importance of Supply Chain Optimization for Walmart

Supply chain optimization is essential for Walmart to maintain its competitive edge. An optimized supply chain can help the company:

- Reduce Costs: Streamlining operations and improving efficiency can lead to significant cost savings.

- Improve Product Availability: Ensuring that the right products are available at the right time enhances customer satisfaction and loyalty.

- Respond Quickly to Market Changes: An agile supply chain allows Walmart to adapt to changing consumer demands and market conditions swiftly.

- Enhance Sustainability: Optimizing the supply chain can reduce the company's carbon footprint and promote environmentally friendly practices.

According to a report by McKinsey & Company, companies that effectively optimize their supply chains can achieve up to a 15% reduction in operational costs while improving service levels.

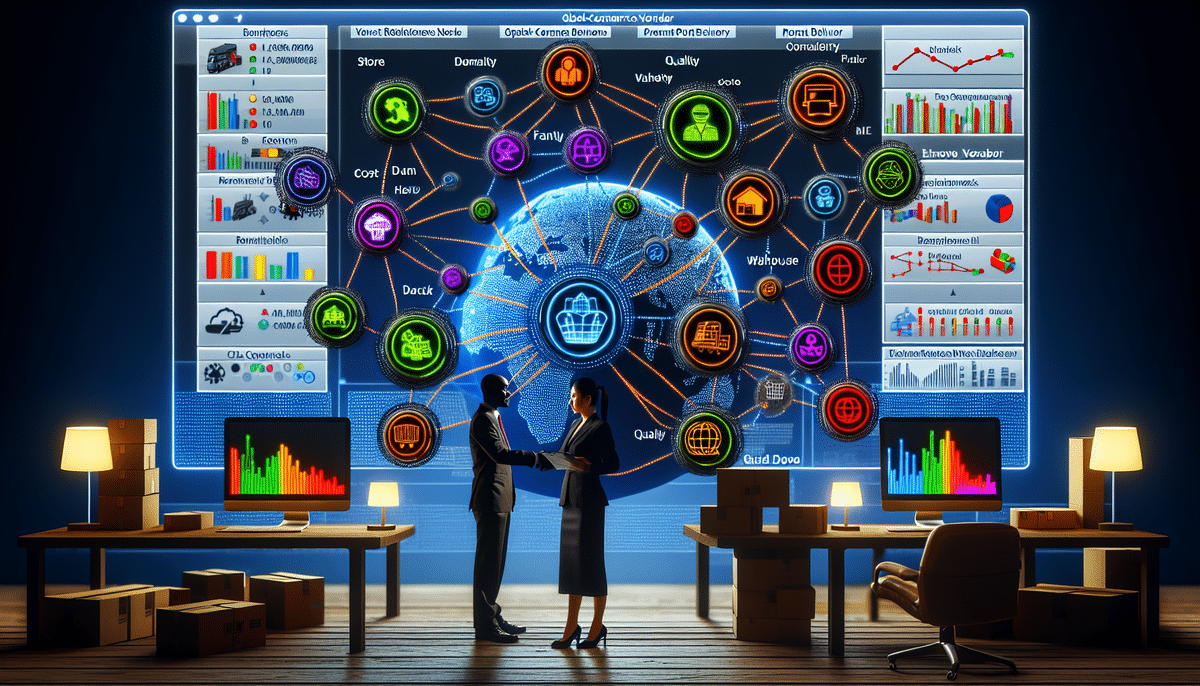

Key Factors Affecting Supply Chain Efficiency

Several factors influence the efficiency of Walmart's supply chain:

- Vendor Management: Collaborating closely with suppliers to ensure they meet quality and delivery standards is crucial for maintaining a smooth supply chain.

- Inventory Control: Implementing just-in-time inventory systems helps in maintaining adequate stock levels while minimizing excess inventory.

- Logistics and Transportation: Efficient management of transportation partners ensures timely and cost-effective delivery of goods.

- Warehouse Management: Optimizing warehouse operations through automation and advanced management systems enhances order fulfillment accuracy and speed.

- Technology Adoption: Leveraging technologies such as IoT, AI, and blockchain improves visibility and traceability across the supply chain.

Integrating these factors effectively can lead to a more resilient and responsive supply chain.

Analysis of Walmart's Supply Chain Operations

Walmart's supply chain is characterized by its complexity and high level of integration. Key initiatives aimed at optimizing its supply chain include:

- Data Analytics: Utilizing data analytics to forecast demand and optimize inventory levels helps Walmart stay ahead of market trends.

- Smart Logistics Technology: Investments in autonomous vehicles and drones aim to enhance transportation efficiency and reduce delivery times.

- Online Marketplace Expansion: Allowing third-party sellers to use Walmart's logistics infrastructure increases product offerings and leverages existing resources.

- Integrated Operations: Seamlessly merging brick-and-mortar and online operations provides a unified shopping experience for customers.

However, maintaining ethical and sustainable practices remains a challenge. Walmart employs supplier scorecards and a Sustainability Index to monitor and evaluate supplier performance regarding environmental and social standards.

Improving the speed and efficiency of last-mile delivery is another focus area. Walmart has experimented with drones and delivery robots, and partnered with third-party logistics providers to enhance delivery capabilities and offer more flexible options to customers.

Best Practices for Supply Chain Optimization

To optimize its supply chain for maximum efficiency, Walmart can implement several best practices:

- Invest in Advanced Technology: Adopting warehouse automation, robotics, and data analytics can streamline operations and enhance decision-making.

- Enhance Vendor Management: Establishing strong relationships with reliable suppliers ensures consistent quality and timely deliveries.

- Optimize Transportation Partnerships: Collaborating with transportation companies that offer reliable and cost-effective services can reduce overall logistics costs.

- Improve Inventory Forecasting: Utilizing predictive analytics to forecast demand accurately helps in maintaining optimal inventory levels, reducing stockouts and excess inventory.

- Implement Sustainable Practices: Reducing waste, minimizing carbon emissions, and using eco-friendly packaging materials not only benefits the environment but also appeals to environmentally conscious consumers.

According to Supply Chain Digital, integrating sustainability into supply chain practices can lead to long-term cost savings and enhance brand reputation.

Implementing Technology Solutions in Walmart's Supply Chain

Technology plays a crucial role in optimizing Walmart's supply chain operations. Key technology solutions include:

- Warehouse Automation and Robotics: Automating order fulfillment processes increases speed and accuracy while reducing labor costs.

- Data Analytics: Leveraging data to forecast demand and optimize inventory helps in making informed decisions and improving efficiency.

- Intelligent Transportation Management Systems: These systems optimize routing and scheduling, reducing transportation costs and improving delivery times.

- Blockchain Technology: Implementing blockchain increases transparency and traceability, ensuring products are ethically sourced and reducing the risk of counterfeit items entering the supply chain.

For instance, Walmart has been a pioneer in using blockchain to trace the origin of its products. According to IBM, blockchain technology allows Walmart to track products from suppliers to stores, enhancing transparency and ensuring compliance with ethical standards.

Strategies for Reducing Costs and Improving Efficiency

Reducing costs while improving efficiency is vital for Walmart's supply chain optimization. Strategies to achieve this include:

- Consolidating Shipments: Combining shipments can reduce transportation costs and optimize logistics operations.

- Optimizing Warehouse Operations: Streamlining warehouse processes minimizes labor costs and enhances order fulfillment accuracy.

- Real-Time Inventory Tracking: Implementing real-time tracking systems reduces stockouts and excess inventory, leading to cost savings.

- Collaborative Cost-Reduction Initiatives: Partnering with vendors to develop joint initiatives can identify areas for cost savings and process improvements.

- Leveraging Data Analytics: Analyzing sales, inventory, and transportation data helps identify inefficiencies and areas where costs can be reduced.

By adopting these strategies, Walmart can achieve a more efficient and cost-effective supply chain, enhancing overall business performance.

Evaluating the Impact of an Optimized Supply Chain on Business Performance

Optimizing the supply chain has a profound impact on Walmart's business performance:

- Cost Savings: Streamlined operations and reduced inefficiencies lead to significant cost reductions.

- Faster Product Delivery: Improved logistics and transportation efficiency enhance delivery speeds, boosting customer satisfaction.

- Increased Customer Satisfaction: Ensuring product availability and timely delivery strengthens customer loyalty and repeat business.

- Competitive Advantage: An optimized supply chain allows Walmart to offer lower prices and faster services, maintaining its position as a retail leader.

- Sustainability Improvements: Enhanced supply chain practices reduce the company's environmental impact, appealing to eco-conscious consumers and improving brand reputation.

Studies by PwC indicate that companies with optimized supply chains can achieve up to a 20% increase in operational efficiency, directly contributing to improved business performance and profitability.

Future Trends and Innovations in Supply Chain Optimization

Looking ahead, retailers like Walmart are expected to adopt several emerging trends and innovations to further optimize their supply chains:

- Advanced Data Analytics Tools: Developing more sophisticated analytics to forecast demand with greater accuracy and optimize inventory levels.

- Blockchain Technology: Expanding the use of blockchain for enhanced security and transparency in the supply chain network.

- Autonomous Vehicles and Drones: Investing in autonomous transportation solutions to improve delivery efficiency and reduce costs.

- Artificial Intelligence and Machine Learning: Utilizing AI and machine learning to identify potential bottlenecks, predict maintenance needs, and automate supply chain processes.

- Internet of Things (IoT): Implementing IoT devices for real-time tracking and monitoring of goods throughout the supply chain.

According to a Gartner report, the adoption of AI and machine learning in supply chain management is expected to grow by 30% over the next five years, driven by the need for increased efficiency and responsiveness.

Conclusion and Recommendations for Optimizing Walmart's Supply Chain

Optimizing Walmart's supply chain for maximum efficiency is critical to the company's continued success. By prioritizing vendor management, logistics, inventory control, and embracing new technologies like automation and data analytics, Walmart can streamline its operations and reduce costs. With competition in the retail industry intensifying, optimizing its supply chain is more important than ever for Walmart.

To further optimize its supply chain, Walmart should focus on the following recommendations:

- Enhance Sustainability Initiatives: Implementing environmentally-friendly practices, such as reducing packaging waste and utilizing renewable energy sources, can reduce Walmart's carbon footprint and appeal to sustainability-focused consumers.

- Invest in Employee Training and Development: Providing comprehensive training programs ensures that employees possess the necessary skills to manage the supply chain effectively, improving overall efficiency and reducing operational errors.

- Adopt Advanced Technologies: Continuously investing in cutting-edge technologies like AI, IoT, and blockchain can further enhance supply chain visibility, responsiveness, and security.

- Strengthen Supplier Relationships: Building strong, collaborative relationships with suppliers ensures compliance with quality standards and fosters innovation within the supply chain.

- Implement Robust Risk Management Strategies: Developing comprehensive risk management plans can help Walmart mitigate potential disruptions and maintain supply chain resilience in the face of unforeseen challenges.

By following these recommendations, Walmart can achieve a more efficient, resilient, and sustainable supply chain, ensuring its position as a leader in the global retail market.