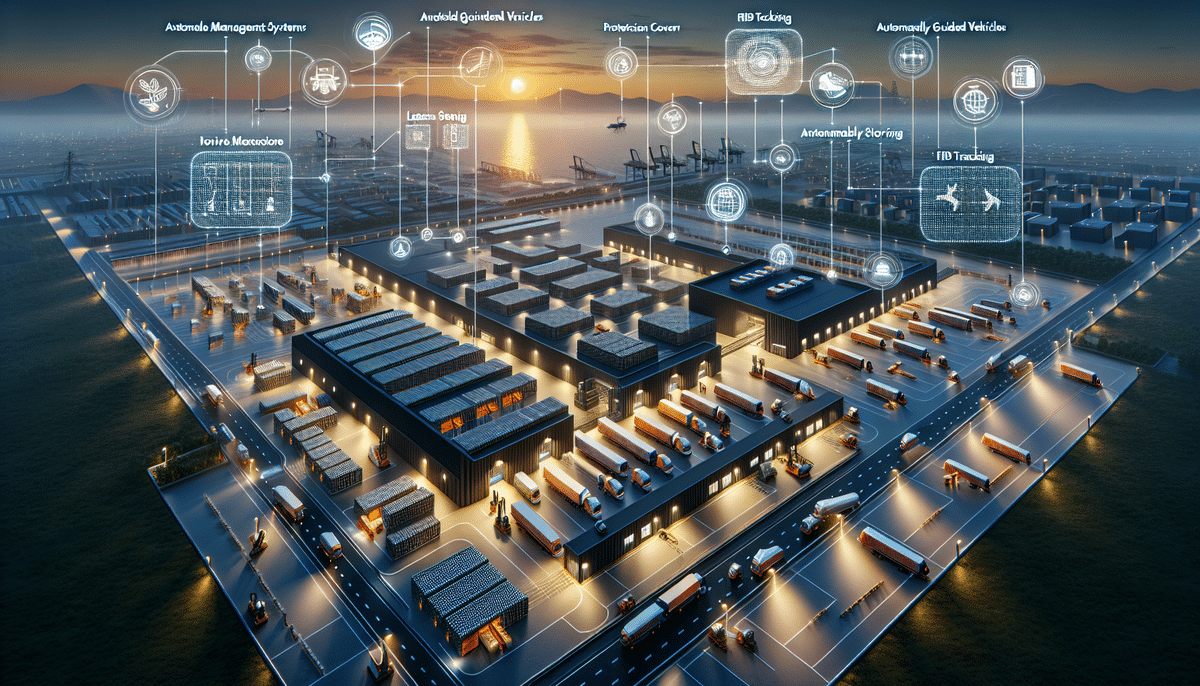

Optimizing Yard Storage for an Efficient Supply Chain

In today’s competitive business landscape, companies must innovate to streamline their supply chain operations. One often overlooked area is yard storage management. Effective yard storage management can help businesses optimize inventory control, enhance visibility, and reduce costs. This article explores the importance of efficient yard storage in supply chain management and provides strategies to optimize yard storage for maximum efficiency.

The Importance of Efficient Yard Storage in Supply Chain Management

Yard storage is a crucial component of the supply chain, serving as the vital link between manufacturing and distribution. It involves the storage, staging, and movement of products within a facility’s designated yard area. Efficient yard storage management is essential because it helps businesses optimize inventory control and improve visibility throughout the supply chain. According to a 2023 Supply Chain Report, companies with optimized yard storage systems saw a 15% reduction in operational costs.

Furthermore, effective yard storage management can help reduce a business’s carbon footprint by minimizing the time trucks spend idling and waiting for products to be loaded or unloaded. This reduction in fuel consumption and emissions not only benefits the environment but also aids businesses in meeting their sustainability goals. Implementing efficient yard storage practices enables businesses to enhance their overall supply chain operations while contributing to a more sustainable future.

Effective Strategies for Optimizing Yard Storage for Businesses

One effective strategy for optimizing yard storage is to implement a Yard Management System (YMS). A YMS is a software solution that enables real-time management of yard storage operations. By providing real-time visibility into yard inventory, a YMS allows businesses to optimize operations and reduce costs. Studies have shown that businesses using YMS can achieve up to a 20% improvement in yard efficiency (ShipScience YMS Benefits).

Improving collaboration between logistics providers and customers is another effective strategy. Enhanced communication and coordination among all parties in the supply chain can lead to better yard storage optimization. Implementing a collaborative platform can facilitate information sharing and streamline operations.

Additionally, optimizing the yard layout to maximize space utilization is crucial. Utilizing vertical storage solutions, such as stacking containers or using high shelves, can increase storage capacity without the need to expand the yard. Implementing a First-In, First-Out (FIFO) system ensures that older inventory is used first, reducing the risk of spoilage or obsolescence. For more on FIFO, visit our detailed FIFO guide.

Understanding the Role of Yard Storage in Supply Chain Operations

Yard storage plays a critical role in supply chain operations by providing a staging area for products before they are shipped to their final destination. Optimizing yard storage can enhance supply chain efficiency, reduce costs, and improve customer satisfaction. A well-managed yard allows businesses to track inventory levels accurately, ensuring that they have the right products to meet customer demand, thereby reducing the risk of stockouts and overstocking.

Moreover, yard storage streamlines the shipping process by centralizing product staging. This centralization facilitates the coordination of loading and unloading trucks, reducing wait times and enhancing overall efficiency. This is particularly important for industries with tight delivery windows, such as retail and healthcare.

How to Maximize Yard Space and Improve Productivity in Warehousing

Maximizing yard space and improving productivity in warehousing can be achieved through the implementation of automation technologies. Automated Guided Vehicles (AGVs), conveyor systems, and robotic systems can optimize yard storage operations by automating the handling and movement of products. According to a McKinsey report, automation can increase yard productivity by up to 30%.

Implementing a well-organized layout also plays a significant role. Grouping similar products, creating designated areas for specific product types, and using a clear labeling system can enhance space utilization and reduce retrieval times.

Investing in employee training and development is another key factor. Properly trained employees can reduce errors, increase efficiency, and boost overall productivity. Regular training sessions, performance incentives, and fostering a collaborative work environment contribute to a more efficient yard operation.

Best Practices for Managing Yard Storage and Inventory Control

Effective management of yard storage and inventory control involves a combination of best practices and advanced technologies. Implementing a lean inventory management system, optimizing space utilization through effective yard layout design, and minimizing the time products spend in the yard with real-time inventory tracking technologies are essential best practices.

Regular inventory audits are crucial for maintaining accuracy and identifying discrepancies. These audits help prevent stockouts and overstocking, which can lead to lost sales and increased costs. Proper labeling and organization of products further enhance efficiency and reduce the risk of errors. By adopting these best practices and leveraging the latest technologies, businesses can effectively manage yard storage and inventory control, leading to increased productivity and profitability.

Streamlining Distribution Processes with Proper Yard Storage Planning

Proper yard storage planning is vital for streamlining distribution processes. It involves balancing space utilization with efficient product movement. Incorporating processes like cross-docking, consolidation, and deconsolidation can significantly enhance distribution efficiency.

Cross-docking involves unloading products from incoming trucks and loading them directly onto outbound trucks without intermediate storage. This process reduces handling time and improves distribution efficiency.

Consolidation combines smaller shipments into larger ones, reducing transportation costs and improving delivery times. Conversely, deconsolidation breaks down larger shipments into smaller ones for distribution to multiple locations.

Implementing technology solutions such as yard management systems can further optimize yard space utilization, improve inventory accuracy, and reduce the time and effort required for manual yard checks. Combining effective yard storage planning with these technology solutions can lead to significant improvements in distribution processes, enhancing efficiency and profitability.

Key Benefits of Implementing an Efficient Yard Storage System

Implementing an efficient yard storage system offers numerous benefits, including improved inventory control and visibility, reduced operating costs, enhanced productivity, minimized risks associated with weather conditions, and increased customer satisfaction and loyalty.

An efficient yard storage system also reduces the risk of theft and damage to goods. A well-organized and secure storage system protects inventory from potential theft or damage caused by weather or other external factors.

Additionally, an efficient yard storage system aids in better supply chain management. By providing a clear understanding of inventory levels and storage capacity, companies can make informed decisions about product ordering, reducing waste and improving overall efficiency.

Top Challenges Faced by Businesses in Optimizing Yard Storage and Solutions

Businesses often face several challenges in optimizing yard storage, including limited space, lack of visibility, inefficient product movement, and the need for real-time tracking and inventory management. Solutions to these challenges include implementing a Yard Management System (YMS), optimizing yard layout design, using automation technologies, and enhancing collaboration between logistics providers and customers.

Another significant challenge is the lack of standardization in yard management processes. Different logistics providers may follow varying procedures, complicating operations. To overcome this, businesses can collaborate with their logistics providers to establish standardized yard management processes, ensuring consistency across all parties.

Using Technology to Optimize Yard Storage, Improve Visibility, and Reduce Costs

Technology is pivotal in optimizing yard storage, improving visibility, and reducing costs. Technologies such as sensors, RFID, and real-time tracking systems enhance yard storage operations by providing real-time visibility into yard inventory. These technologies enable businesses to optimize operations for maximum efficiency.

Beyond improving efficiency, technology helps reduce costs associated with yard storage. Real-time tracking systems minimize the time and resources spent on manual inventory checks and lower the risk of lost or misplaced inventory. Additionally, sensors and RFID technologies help identify and address potential issues like overstocking or underutilization of space before they escalate into costly problems.

The Impact of Weather Conditions on Yard Storage and How to Mitigate Risks

Weather conditions significantly impact yard storage operations. To mitigate risks associated with inclement weather, businesses should implement protective covers, use appropriate storage methods for climate-sensitive products, and deploy real-time inventory tracking technologies to minimize disruptions. According to the National Weather Service, proper planning can reduce weather-related disruptions by up to 25%.

Future Trends in Supply Chain Management: Innovations in Yard Storage Optimization

The future of supply chain management includes continued innovation in yard storage optimization. Emerging trends encompass the increased use of automation technologies, integration of real-time tracking systems into yard storage operations, and the enhanced use of data analytics to optimize yard storage. These innovations are expected to drive further efficiency and cost reductions in supply chain operations.

Measuring the Effectiveness of Your Yard Storage Strategy: Metrics to Track and Analyze

To measure the effectiveness of a yard storage strategy, businesses should track and analyze key metrics such as inventory turnover, cycle time, dwell time, and fill rate. Monitoring these metrics helps identify areas for improvement and implement strategies to optimize yard storage operations for maximum efficiency. Utilizing a Yard Management System (YMS) can facilitate the tracking of these metrics, providing actionable insights for continuous improvement.

The Role of Collaboration between Logistics Providers and Customers in Efficient Yard Management

Collaboration between logistics providers and customers is critical for efficient yard management. By working together, these stakeholders can enhance yard storage operations through improved communication and coordination, optimized yard layout design, and the implementation of real-time tracking technologies. Effective collaboration ensures that all parties are aligned, leading to smoother operations and better overall supply chain performance.

In conclusion, optimizing yard storage is an essential component of supply chain management. By implementing effective strategies and leveraging advanced technologies, businesses can optimize yard storage operations for maximum efficiency, improve visibility, reduce costs, and enhance customer satisfaction and loyalty. Successful yard storage management requires a combination of best practices, cutting-edge technologies, and strong collaboration between logistics providers and customers.