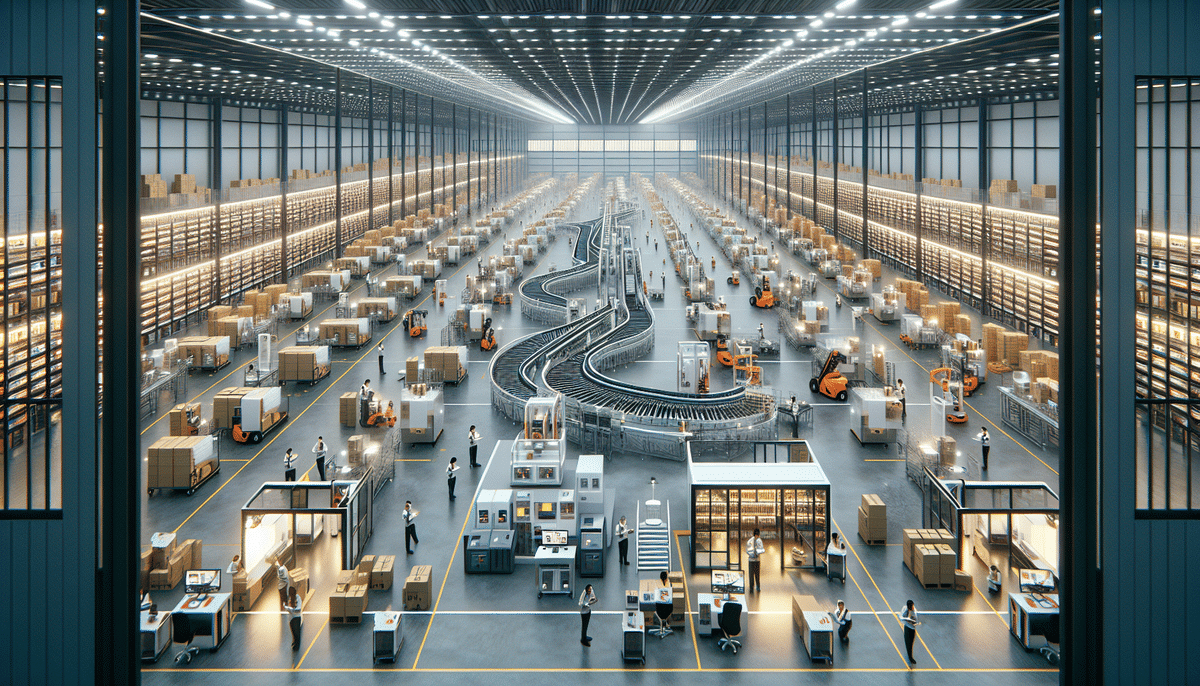

Importance of Warehouse Layout in E-Commerce Logistics

In the realm of e-commerce, the warehouse serves as the backbone of your supply chain. A strategically designed warehouse layout is crucial for enhancing efficiency, speed, and accuracy in your operations. Optimizing your warehouse layout can significantly improve fulfillment processes and boost sales by ensuring that orders are processed swiftly and accurately.

Flow of Goods

The layout of your warehouse dictates the movement of goods from receiving to storage, and finally to picking and packing. An inefficient layout can lead to bottlenecks, slow operations, and increased error rates, ultimately affecting your ability to meet customer demands.

Operational Efficiency

A well-organized warehouse layout streamlines processes, reduces the time required for each operational step, and enhances overall productivity. This leads to faster order fulfillment and a better customer experience.

Benefits of Optimizing Warehouse Layout

Optimizing your warehouse layout offers numerous advantages that can transform your e-commerce logistics:

Increased Efficiency and Speed

An optimized layout minimizes the distance employees need to travel, speeding up the picking and packing processes. This results in faster order processing and quicker delivery times, which are critical factors in customer satisfaction.

Enhanced Accuracy

Structured layouts reduce the likelihood of errors in order fulfillment. By organizing products logically and using automation where possible, you can ensure orders are picked correctly, leading to higher accuracy rates.

Cost Savings

Efficient layouts can lead to significant cost reductions by optimizing space utilization, reducing labor costs through automation, and minimizing the need for additional staff or equipment.

Improved Inventory Management

Optimizing your layout helps in better inventory organization, reducing the chances of stockouts or overstocks. This ensures that you always have the right products available to meet customer demand.

Designing an Effective Warehouse Layout for E-Commerce

Creating a warehouse layout that supports e-commerce fulfillment involves careful planning and consideration of several key factors:

Minimizing Travel Distance

Arrange your warehouse to minimize the distance workers need to travel to pick and pack items. Group frequently purchased items together and position packing stations centrally to enhance efficiency.

Utilizing Automation Technology

Incorporate automated systems such as conveyor belts, robotic pickers, and automated storage and retrieval systems (AS/RS) to speed up processes and reduce human error. According to a report by McKinsey & Company, automation can improve warehouse productivity by up to 25%.

Implementing Data Analytics

Use data analytics to analyze sales trends and customer behavior. This information can help you position high-demand products strategically, optimize inventory levels, and anticipate peak ordering times.

Flexible and Scalable Design

Design your layout to be adaptable to changing business needs. A flexible layout allows for easy adjustments as your order volume grows or product lines expand.

Leveraging Technology in Warehouse Optimization

Technology plays a pivotal role in optimizing warehouse layouts for e-commerce logistics. Implementing advanced technologies can lead to significant improvements in efficiency and accuracy:

Warehouse Management Systems (WMS)

Implementing a robust Warehouse Management System can automate tracking, inventory management, and order processing, providing real-time data and enhancing decision-making.

Internet of Things (IoT)

IoT devices enable real-time tracking of inventory and equipment, providing valuable insights into warehouse operations. According to a study by Supply Chain Digital, integrating IoT in warehouses can improve operational efficiency by 20%.

Robotic Process Automation (RPA)

Robotic systems can handle repetitive tasks such as picking and packing, reducing labor costs and increasing accuracy. The use of robots in warehouses can lead to a 30% increase in order processing speed, as reported by Forbes.

Best Practices and Avoiding Common Mistakes

To ensure the effectiveness of your warehouse layout, adhere to the following best practices and avoid common pitfalls:

Best Practices

- Regular Layout Reviews: Continuously evaluate and adjust your layout to adapt to changing needs and new technologies.

- Employee Training: Train your staff on the layout and the use of any new technologies to ensure smooth operations.

- Clear Signage and Lighting: Implement clear signage and adequate lighting to enhance navigation and safety within the warehouse.

Common Mistakes to Avoid

- Overcrowding: Avoid cluttered spaces that can lead to inefficiencies and safety hazards.

- Poor Space Utilization: Ensure that every inch of your warehouse is used effectively, avoiding wasted space.

- Lack of Flexibility: Design your layout to be adaptable to future changes in inventory or order volumes.

Measuring and Ensuring Continuous Improvement

Continuous improvement is essential for maintaining an optimized warehouse layout. Implement the following strategies to measure success and drive ongoing enhancements:

Key Metrics to Track

- Order Cycle Time: The total time from receiving an order to its shipment. Shorter cycle times indicate greater efficiency.

- Inventory Accuracy: The accuracy of inventory records compared to actual stock levels. High accuracy reduces the risk of stockouts and overstocks.

- Picking Accuracy: The percentage of orders picked correctly. Higher picking accuracy leads to increased customer satisfaction.

Implementing Continuous Improvement Methodologies

Adopt methodologies such as Lean Warehousing and Six Sigma to systematically reduce waste, improve processes, and enhance overall efficiency. These approaches focus on identifying inefficiencies and implementing data-driven solutions.

Fostering a Culture of Feedback

Encourage feedback from warehouse staff and customers to identify areas for improvement. Regularly solicit input and involve your team in the optimization process to foster innovation and collaboration.

Conclusion

Optimizing your e-commerce warehouse layout is a strategic investment that can yield significant benefits in terms of efficiency, accuracy, and customer satisfaction. By leveraging advanced technologies, adhering to best practices, and committing to continuous improvement, you can create a warehouse environment that supports rapid growth and meets the dynamic demands of the e-commerce market.

Further Resources

For more insights and tailored solutions on warehouse optimization, consider exploring resources from industry leaders such as Cisco's Warehouse Logistics Solutions and Supply Chain Digital.