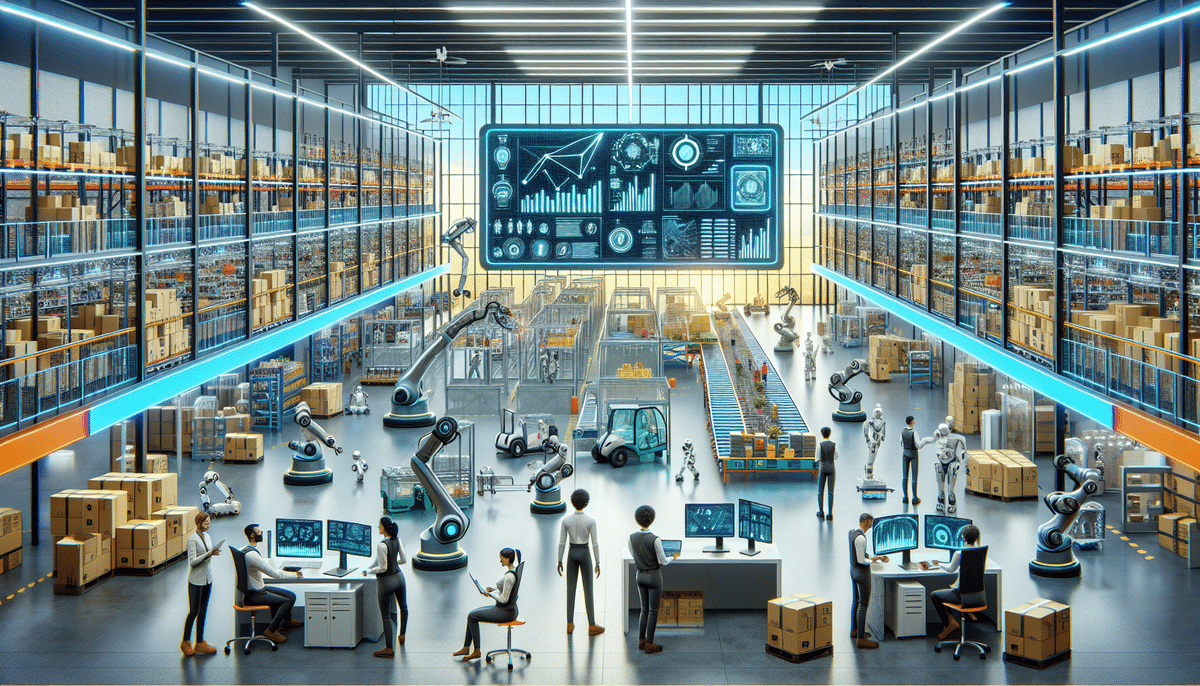

Pushing Warehouse Automation Beyond Robots: Automation in an Omnichannel Warehouse

In today's fast-paced world of online commerce, warehouses must evolve beyond traditional storage facilities. They need to transform into dynamic hubs capable of handling multiple tasks, including customer order fulfillment and distribution. This shift is facilitated by omnichannel warehousing, which leverages the latest automation technologies to enhance efficiency, accuracy, and cost-effectiveness. By adopting these advanced systems, warehouses can manage orders swiftly and accurately, minimizing expenses and boosting customer satisfaction.

The Rise of Omnichannel Warehousing: Why Automation is Key

Omnichannel warehousing expands the role of traditional warehouses beyond storage and pick-and-pack logistics. These warehouses cater to multiple distribution channels, including e-commerce, brick-and-mortar stores, and mobile sales platforms. This versatility is crucial for modern supply chains, ensuring that customers receive their products promptly and accurately across various channels.

Traditional warehousing methods often lead to inefficiencies, causing delays, errors, and higher operational costs. However, automation technology offers a solution by streamlining operations and reducing the time and costs associated with manual processes.

According to a 2023 McKinsey report, automated warehouses can handle up to 30% more orders with 25% greater accuracy compared to manual systems. By implementing automation, companies can enhance their ability to meet the growing demand for omnichannel distribution, staying competitive in an ever-evolving marketplace.

Understanding the Benefits of Warehouse Automation Beyond Robots

While robotics are a prominent aspect of warehouse automation, modern technologies encompass much more. Automation can enhance nearly every facet of warehouse management, leading to significant improvements in efficiency and cost savings.

- Automated Inventory Management: Systems utilizing RFID or barcode technology provide real-time tracking of stock levels, preventing overstocking and understocking.

- Conveyor Systems: Automated conveyors transport goods throughout the warehouse, allowing workers to focus on more strategic tasks.

- Automated Packaging: Packaging machines streamline the order fulfillment process, reducing costs and increasing speed.

Furthermore, automation enables robust data collection and analysis. Automated systems monitor the movement of goods, task completion times, and other critical metrics. This data-driven approach allows for continuous improvement and operational optimization. Enhanced accuracy through automation also leads to higher customer satisfaction and fewer returns, critical factors in maintaining a positive brand reputation.

From Picking to Packing: How Automation is Streamlining Warehouse Operations

One of the most immediate impacts of automation is in the picking and packing processes. These traditionally labor-intensive tasks can now be handled by advanced robotics and conveyor systems, significantly increasing throughput and reducing labor costs.

Automated packing systems utilize barcode verification to ensure items are correctly labeled and packaged, minimizing the risk of shipping errors. This precision not only enhances customer satisfaction but also reduces the costs associated with returns and reshipping.

Moreover, automation optimizes inventory management through sensors and real-time data analysis. Automated systems monitor inventory levels, alerting managers to low stock and enabling efficient restocking. This reduces the risk of stockouts and ensures that products are readily available to meet customer demand.

Data from a Business Insider research shows that warehouses adopting automated picking and packing systems can reduce order processing time by up to 50%, leading to faster delivery times and improved operational efficiency.

Integrating Automation into an Omnichannel Warehouse: Challenges and Solutions

Implementing automation technology in an omnichannel warehouse presents several challenges, including high upfront costs and the need for staff training. Additionally, integrating new systems into existing operations requires careful planning and restructuring.

One effective solution is partnering with experienced technology providers who can assist in identifying suitable automation solutions and guiding the integration process. These providers can offer expertise in system implementation, staff training, and ongoing maintenance, ensuring a smooth transition to automated operations.

Another challenge is the potential need to restructure warehouse operations to fully leverage automation technology. This may involve reorganizing workflows, updating processes, and reassigning roles to align with the automated systems. While this restructuring can be time-consuming, it is essential for maximizing the benefits of automation.

Despite these challenges, the benefits of automation integration are substantial. Automated warehouses report up to a 40% increase in productivity and a 20% reduction in operational costs, according to Supply Chain Dive. By investing in automation and overcoming integration challenges, businesses can achieve significant competitive advantages.

The Role of Artificial Intelligence in Automating Warehouse Processes

Artificial intelligence (AI) is revolutionizing warehouse automation by introducing advanced capabilities such as machine learning and predictive analytics. AI-driven systems can enhance order fulfillment, inventory management, and maintenance processes.

For example, AI-powered inventory management systems can forecast demand with high accuracy, automating the ordering and stocking processes to maintain optimal inventory levels. Additionally, AI-based predictive maintenance can identify potential equipment failures before they occur, minimizing downtime and maintenance costs.

AI also plays a crucial role in optimizing warehouse layout and design. By analyzing data on product movement and order fulfillment patterns, AI algorithms can recommend the most efficient warehouse configurations, reducing travel time and enhancing productivity.

According to a 2023 Forbes study, warehouses utilizing AI for inventory management experience a 35% improvement in inventory accuracy and a 25% reduction in stockouts.

Maximizing Efficiency and Accuracy with Automated Inventory Management Systems

Automated inventory management systems are central to modern warehouse operations. Utilizing technologies such as barcoding and RFID, these systems provide real-time tracking of inventory levels, ensuring accurate stock management.

Integration with other automated systems, like conveyor belts and labeling machines, further streamlines warehouse processes. This interconnectedness reduces the likelihood of inventory discrepancies and accelerates order fulfillment.

Automated inventory systems also generate detailed analytics reports, offering insights into inventory levels, sales trends, and order fulfillment rates. These insights empower businesses to make informed decisions regarding inventory replenishment and product assortment, optimizing stock levels to meet customer demand effectively.

Businesses leveraging automated inventory management report a 20% reduction in inventory holding costs and a 30% increase in order accuracy, according to IBM Industry Data.

The Future of Warehouse Automation: Predictions and Trends to Watch Out For

Warehouse automation is continuously evolving, with new trends and innovations shaping the future of logistics and supply chain management.

- Collaborative Robots (Cobots): Unlike traditional robots, cobots are designed to work alongside human workers, enhancing collaboration and efficiency in warehouse operations.

- AI and Machine Learning: These technologies are set to further transform warehouse management by enabling more sophisticated data analysis, predictive maintenance, and process optimization.

- Modular and Scalable Systems: Automation systems are becoming more flexible, allowing warehouses to quickly adapt to changing consumer demands and operational requirements.

- Sustainable Automation: Increasing emphasis on sustainability is driving the development of energy-efficient automation technologies, such as solar-powered robots and systems utilizing recycled materials.

A recent forecast by Grand View Research predicts that by 2025, the global warehouse automation market will grow by 15% annually, driven by advancements in AI, robotics, and sustainable technologies.

Overcoming Resistance to Change: Tips for Successfully Implementing Automation in a Warehouse

Implementing automation in a warehouse can encounter resistance from employees, budget constraints, and technical challenges. However, strategic approaches can mitigate these obstacles.

- Gradual Implementation: Start by automating the most critical areas of the warehouse, allowing time for adjustment and minimizing disruption.

- Comprehensive Training: Provide thorough training programs to ensure employees are comfortable and proficient with new technologies.

- Employee Involvement: Engage employees in the automation process by seeking their input and incorporating their feedback, fostering a sense of ownership and acceptance.

- Incentives and Rewards: Offer incentives to employees who embrace and excel in using new automation technologies, encouraging a positive attitude towards change.

By implementing these strategies, businesses can facilitate a smoother transition to automated operations, enhancing workforce morale and ensuring the successful adoption of new technologies.

From Small Businesses to Large Corporations: How Automation is Revolutionizing Warehousing for All

Automation technology is not exclusive to large corporations; small and medium-sized businesses are also reaping significant benefits. Implementing automation in warehouses can lead to improved accuracy, faster processing times, and reduced operational costs, irrespective of the business size.

Small businesses can leverage affordable automation solutions, such as cloud-based inventory management systems, to enhance their warehouse operations without substantial upfront investments. These technologies provide scalability, allowing businesses to expand their operations as they grow.

Large corporations benefit from advanced automation systems that handle high-volume order processing, complex inventory management, and intricate logistics. These systems offer robust solutions that can manage extensive operations while maintaining high levels of efficiency and accuracy.

Overall, automation democratizes warehouse efficiency, making it accessible to businesses of all sizes. As online commerce continues to evolve, warehouse automation remains a critical component in meeting customer expectations and maintaining competitive advantage.

One of the key benefits of warehouse automation is the optimization of space utilization. Automated systems maximize the use of available space, reducing the need for additional storage facilities and saving costs. Additionally, automation enhances inventory management, ensuring that products are always available to meet customer demand without overstocking.

Moreover, automation significantly improves workplace safety by automating repetitive or physically demanding tasks, thereby reducing the risk of worker injuries. This leads to a safer work environment, decreased downtime, and uninterrupted operations.