Introduction to Package Dimensioning in E-commerce

The e-commerce industry has experienced exponential growth over the past decade, making efficient shipping and package handling critical components of retail operations. According to Statista, global e-commerce sales are projected to reach $6.4 trillion by 2024. As businesses scale, the need for accurate package dimensioning solutions becomes paramount to optimize shipping processes, reduce costs, and enhance customer satisfaction. Two leading solutions in this space are QubeVu by Postea and Size-IT by Neopost.

Overview of QubeVu by Postea and Size-IT by Neopost

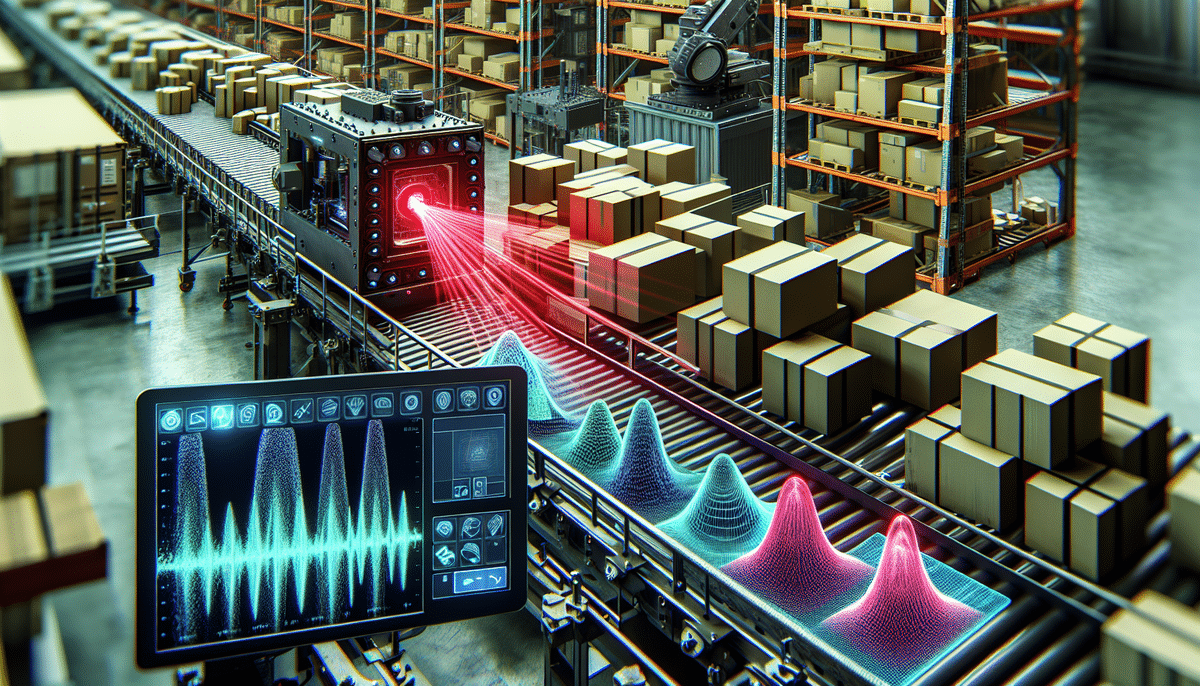

QubeVu and Size-IT are advanced package dimensioning systems designed to streamline shipping operations for businesses. While QubeVu leverages 3D imaging technology to swiftly determine package dimensions and weight, Size-IT uses ultrasonic technology to achieve precise measurements.

QubeVu's 3D imaging capability allows for accurate measurement of irregularly shaped packages, minimizing errors and reducing shipping costs. Its software integrates seamlessly with existing shipping systems, facilitating easy adoption into current business workflows.

Conversely, Size-IT employs ultrasonic sensors to measure packages, making it particularly effective for items with reflective or non-visual surfaces, such as those with glossy or metallic finishes. Size-IT also offers customizable software options, enabling businesses to tailor the system to their specific operational needs.

Importance of Accurate Package Dimensioning in Shipping

Accurate package dimensioning is essential for businesses seeking to optimize their shipping processes and minimize costs. Incorrect dimensions can lead to:

- Additional Shipping Fees: Carriers may charge extra for oversized packages.

- Product Damage: Undersized packaging increases the risk of products being damaged during transit.

- Insufficient Space Utilization: Poorly sized packages can lead to inefficient use of shipping containers and vehicles.

Implementing precise package dimensioning systems ensures that:

- Optimal shipping methods are selected.

- Unnecessary charges are avoided.

- The integrity of package contents is maintained.

Moreover, accurate dimensioning enhances customer satisfaction by ensuring packages arrive in good condition and on time, fostering customer loyalty and positive reviews. It also contributes to reducing the environmental impact by optimizing shipping methods, thereby lowering the company's carbon footprint.

Detailed Comparison: QubeVu vs Size-IT

Features of QubeVu by Postea

QubeVu utilizes state-of-the-art 3D imaging technology, capturing comprehensive images of packages to calculate their dimensions and weight accurately. Key features include:

- High Accuracy: Achieves a 99% accuracy rate in measurements.

- Speed: Can process up to 1,200 packages per hour, ideal for high-volume operations.

- Integration: Easily integrates with existing shipping software, streamlining workflows.

- Image Capture: Provides visual documentation of packages, beneficial for fragile or high-value items.

- Analytics and Reporting: Generates customizable reports to monitor shipping performance.

Features of Size-IT by Neopost

Size-IT employs ultrasonic technology to measure package dimensions by sending and receiving ultrasonic waves. Its features include:

- Ultrasonic Measurement: Effective for accurately measuring packages with reflective or non-visual surfaces.

- LED Display: Provides real-time measurements and system status updates.

- Customizable Invoicing: Allows businesses to tailor invoicing processes to their needs.

- User-Friendly Interface: Simplifies measuring and invoicing with intuitive menus.

- Record Management: Maintains detailed records of measurements and shipping data.

Advantages and Drawbacks

QubeVu Advantages:

- Higher measurement accuracy and speed.

- Seamless integration with existing systems.

- Provides visual documentation of packages.

QubeVu Drawbacks:

- Higher initial cost and space requirements.

Size-IT Advantages:

- Cost-effective with a one-time purchase option.

- Effective for measuring specialized package types.

- User-friendly interface with additional features like LED displays.

Size-IT Drawbacks:

- May struggle with irregularly shaped packages.

- Requires manual positioning of packages, potentially slowing processes.

- Lower accuracy rate compared to QubeVu.

Factors to Consider When Choosing a Package Dimensioning System

Selecting the appropriate package dimensioning system entails assessing various factors to ensure alignment with your business needs:

- Volume of Packages: High-volume shippers may benefit from faster, automated systems like QubeVu.

- Types of Packages: Consider the variety and shapes of packages your business handles.

- Shipping Costs: Evaluate how each system can help optimize shipping costs and avoid additional fees.

- Automation and Integration: Determine the level of automation required and compatibility with existing software.

- Accuracy: Ensure the system provides the necessary accuracy to maintain product integrity and cost efficiency.

- Ease of Use and Maintenance: Choose a system that is user-friendly and requires minimal maintenance to prevent operational downtime.

Implementation and Maintenance Tips

Implementing a Package Dimensioning System

Successfully implementing a package dimensioning system involves several key steps:

- Assess Your Needs: Determine the volume and types of packages you handle to select the most suitable system.

- Select the System: Choose between QubeVu, Size-IT, or another solution based on your assessment.

- Set Up the Equipment: Install the system in your warehouse or shipping area, ensuring proper placement for optimal functionality.

- Integrate with Existing Software: Connect the dimensioning system with your current shipping software to streamline operations.

- Train Your Staff: Provide comprehensive training to employees on how to use the new system effectively.

- Monitor and Optimize: Continuously monitor the system's performance and make necessary adjustments to enhance efficiency.

Maintaining and Calibrating Your Package Dimensioning Equipment

To ensure your package dimensioning equipment remains accurate and reliable, follow these maintenance and calibration tips:

- Regular Cleaning: Keep cameras, sensors, and other components clean to prevent dust and debris from affecting measurements.

- Routine Calibration: Schedule regular calibration sessions to maintain measurement accuracy, following the manufacturer's guidelines.

- Software Updates: Keep the system's software up to date to benefit from the latest features and improvements.

- Inspect Components: Regularly check for any wear and tear or damage to system parts and replace them as needed.

- Employee Training: Ensure that staff members are trained to perform basic maintenance tasks and identify potential issues early.

Case Studies: Companies Using QubeVu and Size-IT

Several prominent companies have successfully integrated QubeVu or Size-IT into their shipping operations:

- FedEx: Adopted QubeVu in their fulfillment centers to enhance shipping efficiency and accuracy.

- UPS: Utilizes Size-IT for accurate package measurements, ensuring cost-effective shipping.

- Amazon: Implemented QubeVu in their warehouses to optimize package measurements, resulting in faster delivery times and reduced shipping costs.

- Shopify: Integrated Size-IT into their shipping process, allowing merchants to easily measure package dimensions and ensure accurate shipping rates, saving time and money while improving customer experience.

Conclusion: Choosing the Right Package Dimensioning Solution for Your Business

Both QubeVu and Size-IT offer unique features and benefits tailored to different business needs. For high-volume shippers seeking to optimize their shipping processes and reduce costs, QubeVu emerges as the superior option due to its speed, accuracy, and seamless integration capabilities. Conversely, businesses with specialized packaging needs or those preferring a one-time investment may find Size-IT more suitable. By carefully evaluating your operational requirements and considering factors such as package volume, types, and accuracy needs, you can select the package dimensioning system that best aligns with your business objectives and drives operational efficiency.