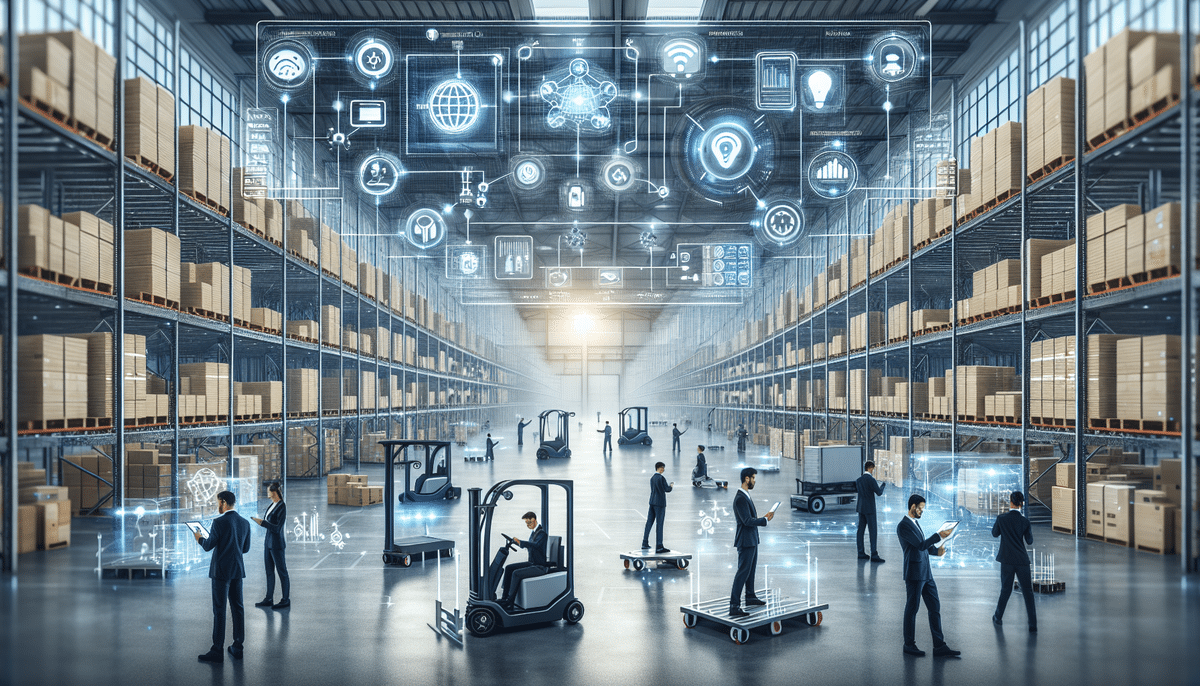

Introduction to IoT in Warehouse Management

The rapid advancement of technology has revolutionized various industries, with warehouse management being no exception. The integration of Internet of Things (IoT) technology into warehouse operations is transforming how businesses manage their inventory, streamline processes, and enhance overall efficiency. This article delves into the critical role of IoT in warehouse management, exploring its benefits, implementation strategies, real-world case studies, and future trends.

Key Benefits of IoT Technology in Warehousing

Improved Operational Efficiency

IoT enables real-time data tracking, allowing warehouses to monitor inventory levels, goods movement, and equipment status dynamically. This real-time visibility aids in making informed decisions, optimizing workflows, and reducing operational costs.

For instance, sensors can detect the exact location of items within the warehouse, minimizing the time spent searching for products and leading to faster order fulfillment.

Statistic: According to a McKinsey report, IoT can boost warehouse efficiency by up to 25%.

Predictive Maintenance

IoT sensors monitor the performance and health of warehouse equipment in real-time. By analyzing this data, potential faults can be detected early, allowing for maintenance to be scheduled before a breakdown occurs.

This proactive approach reduces unplanned downtime, extends the lifespan of equipment, and lowers maintenance costs.

Enhanced Inventory Management

With IoT, warehouses achieve real-time visibility into inventory levels, ensuring optimal stock management. Automated inventory tracking reduces human errors and facilitates accurate forecasting.

Data analytics derived from IoT devices provide insights into demand trends and inventory movement, enabling strategic planning and reducing instances of overstocking or stockouts.

Optimized Space Utilization

IoT devices track the movement of goods and equipment, allowing warehouses to reorganize layouts for maximum storage efficiency. This optimization can lead to significant cost savings by minimizing the need for additional storage space.

Enhanced Safety and Security

IoT sensors detect potential hazards such as spills, equipment malfunctions, or unauthorized access in real-time. Immediate alerts enable staff to take swift action, preventing accidents and ensuring a safer working environment.

Additionally, connected cameras and sensors bolster inventory security by monitoring for suspicious activities, thereby reducing theft and ensuring the integrity of warehouse operations.

Implementing IoT Technology in Warehouses

Identifying Key Areas for IoT Integration

Successful IoT implementation begins with identifying the areas within warehouse operations that can benefit the most from IoT integration. Common areas include inventory management, equipment monitoring, environmental control, and logistics.

Developing a Comprehensive Integration Plan

A detailed integration plan outlines how IoT systems will be incorporated with existing technologies. This plan should address potential disruptions, timelines, and resource allocation to ensure a smooth transition.

Choosing the Right IoT Solutions

Selecting appropriate IoT solutions is crucial for maximizing the benefits of IoT integration. Considerations should include scalability, compatibility with existing systems, vendor support, and security features.

For example, ShipScience's sensors offer robust monitoring capabilities for environmental conditions, ensuring that sensitive goods are stored under optimal conditions.

Training and Staff Development

Ensuring that warehouse staff are adequately trained to use IoT devices and interpret the data is essential. Comprehensive training programs enhance the effectiveness of IoT technology and foster a culture of data-driven decision-making.

Monitoring and Continuous Improvement

Post-implementation, it's vital to continuously monitor IoT systems to assess their performance and impact on warehouse operations. Regular data analysis helps in identifying areas for improvement and adapting to evolving operational needs.

Real-World Case Studies: IoT Success in Warehousing

Walmart

Walmart has integrated IoT sensors into its distribution centers to monitor temperature, humidity, and other environmental factors. This initiative has significantly reduced food waste and enhanced product quality, decreasing spoilage rates by up to 20%.

Bosch

The German automotive giant Bosch utilizes IoT technology to gain real-time visibility into inventory levels in its warehouses. This implementation has minimized stockouts and improved operational efficiency by 15%.

Amazon

Amazon employs IoT in its fulfillment centers for precise inventory tracking and automation. This strategy has accelerated order processing times and boosted customer satisfaction by ensuring timely deliveries.

Challenges and Solutions in Adopting IoT for Warehouse Management

High Implementation Costs

The initial investment for IoT systems can be substantial. However, the long-term savings and efficiency gains often justify the upfront costs.

Solution: Conduct a cost-benefit analysis to understand the potential return on investment and explore financing options or phased implementation strategies.

Complex System Integration

Integrating IoT with existing warehouse management systems can be challenging.

Solution: Utilize middleware solutions and collaborate with experienced IoT providers to facilitate seamless integration.

Data Security Concerns

Increased connectivity through IoT devices elevates the risk of cyber threats.

Solution: Implement robust cybersecurity measures, regular security audits, and ensure that IoT devices comply with industry security standards.

Scalability Issues

As warehouse operations expand, IoT systems must accommodate increased data flow and device connectivity.

Solution: Choose scalable IoT solutions that can grow alongside your business and adapt to future technological advancements.

Future Trends in IoT for Warehousing

Advanced Data Analytics and AI Integration

The integration of artificial intelligence (AI) with IoT will enable more sophisticated data analytics, allowing warehouses to predict demand, optimize inventory, and automate complex tasks with greater accuracy.

Autonomous Systems and Robotics

IoT-driven autonomous systems, such as Automated Guided Vehicles (AGVs) and robotic pickers, will become more prevalent, further reducing the reliance on manual labor and enhancing operational efficiency.

Enhanced Sustainability Practices

IoT will play a pivotal role in promoting sustainability within warehouses by optimizing energy consumption, reducing waste, and enabling more efficient resource management.

Improved Worker Safety and Ergonomics

Future IoT innovations will focus on enhancing worker safety through wearable devices that monitor health metrics and environmental conditions, ensuring a safer and more ergonomic workplace.

Best Practices for Implementing IoT in Warehouse Operations

Start with Clear Objectives

Define specific goals for IoT integration, such as improving inventory accuracy, reducing operational costs, or enhancing safety measures. Clear objectives guide the implementation process and help measure success.

Ensure Data Quality and Management

Accurate and reliable data is essential for effective IoT utilization. Implement robust data management practices to ensure data integrity, security, and accessibility.

Foster a Culture of Continuous Improvement

Encourage ongoing evaluation and adaptation of IoT systems. Regularly assess performance metrics and seek feedback from staff to identify areas for enhancement.

Collaborate with Technology Partners

Partner with reputable IoT solution providers who offer comprehensive support, including installation, maintenance, and training services. Collaboration ensures that your IoT systems are effectively integrated and managed.

Prioritize Security from the Outset

Incorporate security measures into the design and deployment of IoT systems to protect against cyber threats. This includes using encrypted communications, secure access controls, and regular security updates.

Conclusion

The integration of IoT technology is a game-changer for warehouse management, offering unparalleled levels of efficiency, cost savings, and operational transparency. By leveraging real-time data tracking, predictive maintenance, and enhanced inventory management, warehouses can optimize their operations and gain a competitive edge in the market.

While the adoption of IoT presents certain challenges, strategic planning, the right choice of IoT solutions, and adherence to best practices can effectively address these obstacles. As IoT technology continues to evolve, its potential to drive innovation and efficiency in warehouse management will only grow, positioning businesses for sustained success in an increasingly competitive landscape.

Embracing IoT is not just a technological upgrade; it is a strategic initiative towards creating smarter, more resilient, and highly efficient warehouse operations.