Rice Lake iDimension Series vs Honeywell AutoCube 8200

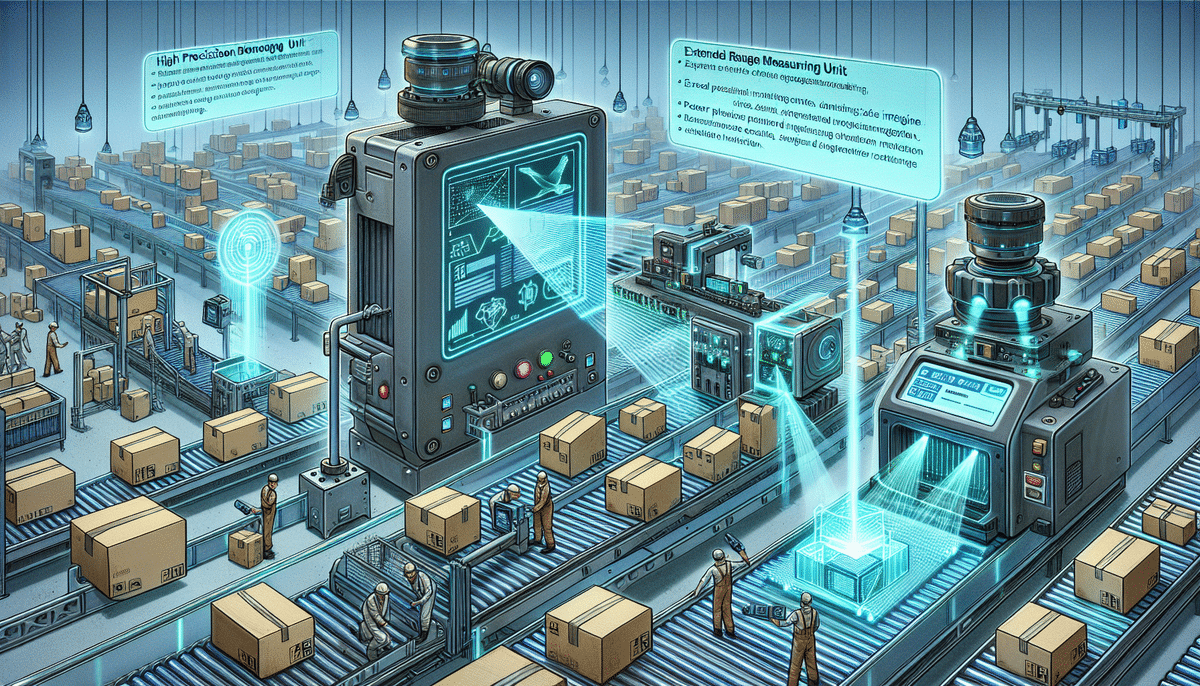

In the logistics industry, precision and accuracy are pivotal for ensuring smooth and efficient operations. Dimensioning systems play a crucial role by providing accurate and reliable measurements of packages, enabling logistics companies to optimize storage space and streamline freight transportation. Among the top contenders in the market are the Rice Lake iDimension Series and the Honeywell AutoCube 8200. This comprehensive comparison delves into their key features, specifications, and performance metrics to help you determine the best fit for your business needs.

Understanding the Need for Dimensioning Systems in the Logistics Industry

Accurate package measurement is essential in logistics for several reasons:

- Efficiency: Automated dimensioning systems significantly reduce the time spent on manual measurements.

- Accuracy: Minimizes human errors, ensuring that package dimensions are precise.

- Cost Optimization: Helps in calculating the dimensional weight of packages, which is crucial for pricing freight transportation correctly.

- Space Utilization: Optimizes storage space within warehouses, leading to better inventory management.

According to a report by Logistics Management, implementing automated dimensioning systems can increase warehouse productivity by up to 30%. Moreover, accurate dimensioning helps in reducing shipping costs by an average of 15%, as highlighted in a Shipping Cost Study 2023.

Comparing Rice Lake iDimension Series and Honeywell AutoCube 8200

The Rice Lake iDimension Series and Honeywell AutoCube 8200 are two leading dimensioning systems, each offering unique features tailored to different business needs. Below is a detailed comparison:

Key Features and Specifications of Rice Lake iDimension Series

- Measurement Speed: Capable of measuring up to 120 packages per minute.

- Measurement Capacity: Can handle packages up to 32 inches (81 cm) in height and weighing up to 150 lbs (68 kg).

- Imaging Technology: Advanced imaging for accurate measurements of various package shapes and sizes.

- Integration: Customizable options to integrate seamlessly with existing software and hardware.

- Data Management: Captures and stores measurement data for future analysis, aiding in informed decision-making.

- Energy Efficiency: Utilizes energy-efficient LED lighting with low power consumption.

- Build Quality: Durable construction designed to withstand the demands of busy warehouse environments.

The Rice Lake iDimension Series also features a user-friendly interface with intuitive controls, making it easy for operators to use and understand. Its built-in calibration system ensures long-term accuracy without the need for frequent manual adjustments.

Key Features and Specifications of Honeywell AutoCube 8200

- Measurement Speed: Measures packages in under two seconds.

- Measurement Capacity: Handles packages up to 39 inches (99 cm) in height and 30 inches (76 cm) in length and width.

- Advanced Algorithms: Utilizes multiple sensors and sophisticated algorithms for highly precise measurements.

- Integration: Cloud-based platform that integrates seamlessly with various warehouse management systems and e-commerce platforms like Shopify and Magento.

- User Interface: Features a simple, user-friendly interface for easy operation and maintenance.

- Data Management: Offers robust data management capabilities, allowing for efficient handling of high-volume package measurements.

The Honeywell AutoCube 8200 is designed for scalability, making it suitable for larger enterprises that require advanced data management and integration capabilities. Its cloud-based platform ensures that data can be accessed and managed from multiple locations, enhancing operational flexibility.

Accuracy Comparison

Both the Rice Lake iDimension Series and Honeywell AutoCube 8200 boast high accuracy, with measurements within a 0.2 inches (5 mm) variation. However, the Rice Lake iDimension Series leverages advanced imaging technology to offer superior accuracy for irregularly shaped packages. Additionally, its built-in calibration system automatically adjusts to maintain consistent measurements over time, eliminating the need for manual calibration.

In contrast, while the Honeywell AutoCube 8200 also provides precise measurements, it relies heavily on multiple sensors and algorithms to achieve accuracy, which can be advantageous in high-volume settings.

Ease of Use

Both systems are designed for ease of setup and operation, but the Rice Lake iDimension Series offers a more straightforward plug-and-play setup, allowing for quick installation without extensive technical knowledge. Its intuitive on-screen instructions and user-friendly interface further simplify operations.

The Honeywell AutoCube 8200 also provides an easy-to-navigate interface but includes additional features such as remote access capabilities. This allows users to monitor and control the system from different locations, which is particularly beneficial for businesses with multiple warehouse sites.

Integration Capabilities

Integration with existing software systems is crucial for seamless operations. Both systems support integration with popular shipping software and hardware solutions. However, the Honeywell AutoCube 8200 stands out with its cloud-based platform, facilitating easy data management and access across various locations. It also offers robust integration with e-commerce platforms like Shopify and Magento, enabling businesses to synchronize online orders and inventory efficiently.

On the other hand, the Rice Lake iDimension Series provides customizable integration options, allowing it to fit seamlessly into existing warehouse management systems. This flexibility makes it a versatile choice for businesses with specific integration requirements.

Maintenance Requirements

Both systems are designed for minimal maintenance, but the Rice Lake iDimension Series has an edge with its advanced imaging technology, which reduces the need for frequent sensor calibration or cleaning. Additionally, its self-diagnostic feature proactively alerts users to potential issues, enabling timely maintenance and preventing unexpected downtime.

The Honeywell AutoCube 8200 also requires minimal maintenance due to its robust build and advanced sensors. However, its reliance on multiple sensors may necessitate occasional calibration to maintain optimal performance.

Cost Comparison

Pricing for dimensioning systems can vary based on specific features and configurations. Generally, the Honeywell AutoCube 8200 is positioned at a higher price point compared to the Rice Lake iDimension Series. This difference is attributed to its advanced data management capabilities and extensive integration options.

When evaluating costs, it's essential to consider both the initial investment and long-term expenses related to maintenance and support. The Honeywell AutoCube 8200's durability and reliability may result in lower maintenance costs over time, potentially offsetting its higher upfront price.

Moreover, Rice Lake is renowned for its exceptional customer service and technical support, which can provide added value and peace of mind for businesses selecting their dimensioning systems.

User Reviews

Both the Rice Lake iDimension Series and Honeywell AutoCube 8200 have garnered positive feedback from users:

- Rice Lake iDimension Series: Users appreciate its ability to accurately measure irregularly shaped packages and its seamless integration with existing warehouse management software. Small to medium-sized businesses find it particularly convenient and cost-effective.

- Honeywell AutoCube 8200: Users highlight its high-speed measurement capabilities, handling over 1,000 packages per hour with ease. Larger enterprises value its advanced data management features and user-friendly interface, which simplifies training and operations.

For instance, one user of the Rice Lake iDimension Series mentioned, "The system has significantly reduced our measurement time and eliminated errors in pricing our shipments," while a Honeywell AutoCube 8200 user stated, "The AutoCube 8200 integrates flawlessly with our e-commerce platform, enhancing our overall operational efficiency."

Which Dimensioning System is Best Suited for Your Business Needs?

Choosing between the Rice Lake iDimension Series and Honeywell AutoCube 8200 depends on your specific business requirements:

- Rice Lake iDimension Series: Ideal for small to medium-sized businesses seeking an affordable, easy-to-use system with advanced imaging technology. Its flexibility in integration makes it suitable for diverse operational setups.

- Honeywell AutoCube 8200: Best suited for larger enterprises that require high-volume handling, advanced data management, and seamless integration with multiple software platforms. Its scalability and robust features cater to complex logistics operations.

Additionally, consider the size and weight of the items you handle. The Rice Lake iDimension Series is optimized for smaller and lighter packages, whereas the Honeywell AutoCube 8200 can efficiently manage larger and heavier shipments. Evaluating your business's current and future needs will guide you in making an informed decision.

Future Trends in Dimensioning Technology

The logistics industry's rapid evolution drives continuous advancements in dimensioning technology. Key trends to watch include:

- Artificial Intelligence and Machine Learning: Enhancing the accuracy and efficiency of dimensioning systems by enabling predictive analytics and automated adjustments.

- 3D Scanning: Allowing for more precise measurements of irregularly shaped objects, which is particularly beneficial for industries like fashion and furniture.

- Drone Integration: Utilizing drones for dimensioning large or hard-to-reach objects, providing faster and more efficient measurements.

- Internet of Things (IoT): Connecting dimensioning systems with other warehouse equipment for real-time data sharing and process optimization.

Staying abreast of these trends will enable logistics companies to adopt cutting-edge solutions, maintaining competitiveness and operational excellence.

Conclusion: The Verdict on Rice Lake iDimension Series vs Honeywell AutoCube 8200

Both the Rice Lake iDimension Series and Honeywell AutoCube 8200 are exemplary dimensioning systems offering reliable and accurate measurements. Your decision should hinge on your business's size, volume, and specific operational needs:

- If you are a small to medium-sized business seeking affordability and ease of use, the Rice Lake iDimension Series is an excellent choice.

- For larger enterprises requiring advanced data management, high-volume handling, and extensive integration capabilities, the Honeywell AutoCube 8200 is more suitable.

Ultimately, assessing your current logistics challenges and future growth plans will guide you to the dimensioning system that aligns best with your objectives, ensuring enhanced efficiency and cost-effectiveness in your operations.