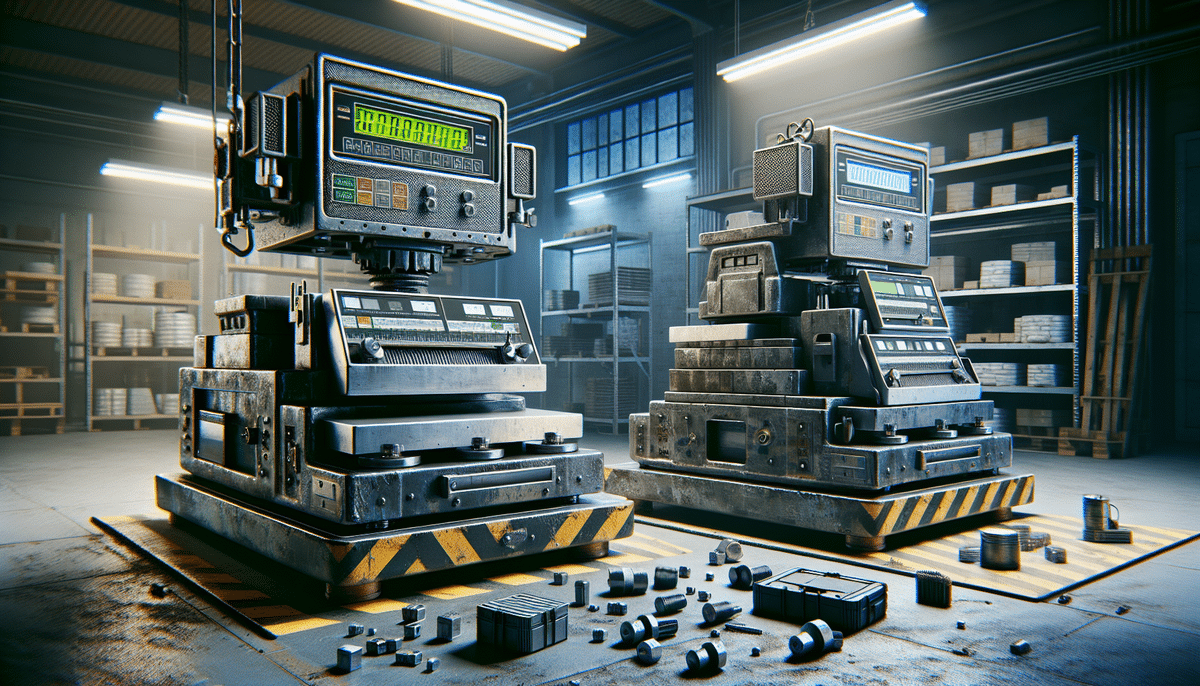

Rice Lake RoughDeck vs PEC Scales: Comprehensive Comparison

When selecting industrial weighing scales, two prominent brands often come into consideration: Rice Lake RoughDeck and PEC Scales. Both are renowned for their durability and precision, but understanding their distinct features is essential for making an informed decision. This article provides an in-depth analysis of key factors to consider when choosing between Rice Lake RoughDeck and PEC Scales.

The Importance of Industrial Weighing Scales

Industrial weighing scales are vital for businesses that handle heavy and bulky items, ensuring accurate weight measurements across various sectors like manufacturing, logistics, agriculture, and mining. Accurate measurements are crucial not only for operational efficiency but also for compliance with regulatory standards, helping businesses avoid fines and maintain quality control.

According to a report by IBISWorld, the global industrial weighing scales market is expected to grow steadily, driven by increasing demand for precision in manufacturing and logistics operations.

Key Factors in Choosing Between Rice Lake RoughDeck and PEC Scales

When deciding between Rice Lake RoughDeck and PEC Scales, consider the following key factors:

Accuracy

Both Rice Lake RoughDeck and PEC Scales are known for their high accuracy. Rice Lake RoughDeck utilizes advanced digital filtering technology to provide stable and precise measurements even in challenging environments. On the other hand, PEC Scales employs precision load-cell technology, ensuring accurate weight measurements under heavy loads.

Durability

Industrial environments can be harsh, with exposure to temperature fluctuations, humidity, dust, and vibrations. Rice Lake RoughDeck stands out with its welded steel design, offering superior strength and longevity. In contrast, PEC Scales features corrosion-resistant coatings, enhancing resilience in environments prone to corrosion.

Capacity

The capacity of a weighing scale determines the maximum weight it can measure accurately. Rice Lake RoughDeck offers capacities ranging from 2,500 lbs to 30,000 lbs, catering to diverse industrial needs. PEC Scales also provides a wide range, from 1,000 lbs up to 30,000 lbs, making them versatile for various applications.

User Interface

A user-friendly interface is crucial for ease of operation and accuracy. Rice Lake RoughDeck features a large display screen for real-time weight readings, enhancing operational efficiency. PEC Scales offers customizable interfaces, including touchscreens and remote displays, catering to different user preferences.

Price

Price is a significant consideration. Generally, Rice Lake RoughDeck models tend to be more expensive due to their advanced technology and robust construction. PEC Scales are slightly more affordable while still offering high-quality options, making them suitable for businesses with tighter budgets.

Maintenance

Regular maintenance and calibration are essential for the longevity and accuracy of industrial scales. Rice Lake RoughDeck requires frequent calibration due to its complex digital systems but features a self-diagnostic system that streamlines maintenance. PEC Scales requires manual calibration and regular cleaning, especially due to their corrosion-resistant coatings.

In-Depth Review: Rice Lake RoughDeck

Rice Lake RoughDeck is a leading name in the industrial weighing scale market, celebrated for its accuracy and durability. The RoughDeck series features a welded steel design, providing exceptional strength suitable for heavy-duty applications. Its advanced digital filtering technology ensures stable and accurate measurements in demanding environments.

The RoughDeck line offers a broad range of capacities from 2,500 lbs to 30,000 lbs, accommodating various industrial needs. The user-friendly interface includes a large display screen that presents real-time weight data, enhancing operational efficiency.

Customization options are a key feature, allowing customers to choose from various sizes, finishes, and accessories such as ramps and pit frames for easy installation and accessibility. Additionally, RoughDeck scales integrate seamlessly with multiple software and data management systems, supporting Ethernet, USB, and RS-232 connectivity for efficient data communication.

For further details, visit the official Rice Lake RoughDeck page.

PEC Scales: Detailed Overview

PEC Scales is another prominent player in the industrial weighing scale industry, known for its precision load-cell technology and corrosion-resistant coatings. PEC Scales offer a versatile range of capacities from 1,000 lbs to 30,000 lbs, making them suitable for diverse applications across different industries.

The user interface is highly customizable, featuring options such as touchscreens, remote displays, and mobile app integrations. This flexibility enhances usability and accessibility, catering to varied operational needs. PEC Scales also provide a comprehensive array of accessories, including ramps, pit frames, and wireless communication modules, to enhance functionality and convenience.

PEC Scales emphasizes quality and customer satisfaction, offering extensive technical support and training to help users maximize the potential of their scales. Regular maintenance and calibration services are available to ensure ongoing accuracy and reliability.

Learn more on the PEC Scales official page.

Performance Comparison: Rice Lake RoughDeck vs PEC Scales

Both Rice Lake RoughDeck and PEC Scales deliver exceptional performance in accuracy and durability. RoughDeck's digital filtering technology ensures stable measurements in demanding environments, while PEC Scales' precision load-cell technology maintains accuracy under heavy loads.

In terms of user interface, RoughDeck offers a straightforward, large display screen, whereas PEC Scales provide more customizable options like touchscreens and remote displays.

Regarding capacity, RoughDeck generally offers higher weight capacities, making it more suitable for extremely heavy loads. Additionally, RoughDeck scales come with built-in overload protection systems to prevent damage from overloading.

Maintenance-wise, RoughDeck features a self-diagnostic system that alerts users when calibration is needed, simplifying maintenance processes. PEC Scales require manual calibration and cleaning, which can be more time-consuming but allows for precise adjustments.

For a detailed comparison, refer to industry analyses such as those by GlobalSpec.

Features and Benefits of Rice Lake RoughDeck

Rice Lake RoughDeck offers several notable features and benefits:

- Advanced digital filtering technology ensures stable weight measurements

- Welded steel design provides superior strength and durability

- Wide capacity range from 2,500 lbs to 30,000 lbs

- Large display screen for real-time weight readings

- Customization options including ramps, pit frames, and various accessories

- Compatibility with multiple software and data management systems

- Connectivity options such as Ethernet, USB, and RS-232 ports

Additionally, Rice Lake RoughDeck is backed by exceptional customer service and technical support, ensuring optimal performance and user satisfaction.

Advantages and Disadvantages of PEC Scales

PEC Scales present several advantages and some drawbacks:

- Precision load-cell technology ensures accurate measurements under heavy loads

- Corrosion-resistant coatings enhance durability in harsh environments

- Customizable user interfaces with options like touchscreens and remote displays

- Wide capacity range from 1,000 lbs to 30,000 lbs

- Comprehensive range of accessories and options, including wireless communication modules

- Higher initial cost compared to some RoughDeck models

- May require more frequent calibration and maintenance

PEC Scales are versatile, handling a wide range of weights suitable for businesses with diverse weighing needs. However, their size and weight can make them less portable and necessitate dedicated installation space. The higher initial investment may also be a barrier for businesses with limited budgets.

Pricing Comparison: Rice Lake RoughDeck vs PEC Scales

When considering pricing, Rice Lake RoughDeck scales are generally more affordable compared to PEC Scales, primarily due to the advanced features and customization options that PEC Scales offer. However, it's crucial to consider not only the initial purchase price but also the long-term costs associated with maintenance and calibration. Investing in scales that offer lower maintenance costs and higher durability can lead to significant cost savings over time.

For detailed pricing information, consult industry pricing guides such as those provided by IndustrySelect.

Customer Reviews and Ratings

Customer feedback is invaluable in assessing the performance and reliability of Rice Lake RoughDeck and PEC Scales. Both brands have received positive reviews for their durability, accuracy, and ease of use.

Rice Lake RoughDeck is frequently praised for its robust construction and advanced digital filtering technology, which contribute to consistent performance in demanding environments.

PEC Scales earn commendations for their precise load-cell technology and highly customizable user interfaces, making them adaptable to various operational needs. However, some customers have noted the need for more frequent calibration and maintenance, underscoring the importance of regular upkeep to maintain accuracy.

For comprehensive customer reviews, visit industry forums and the respective Rice Lake RoughDeck and PEC Scales product pages.

Maintenance and Calibration Best Practices

Maintaining and calibrating industrial weighing scales is essential for ensuring accuracy and longevity. Both Rice Lake RoughDeck and PEC Scales require regular maintenance routines:

- Regular cleaning to remove dust and debris

- Lubrication of moving parts for smooth operation

- Replacement of worn or damaged components as needed

Calibration is crucial for maintaining measurement accuracy and may be required periodically or after significant repairs or adjustments. Rice Lake RoughDeck scales feature a self-diagnostic system that notifies users when calibration is necessary, simplifying the maintenance process. PEC Scales require manual calibration, which, while more time-consuming, allows for precise adjustments tailored to specific operational needs.

Adhering to the manufacturer's maintenance and calibration guidelines is vital. Refer to industry standards such as those from the National Institute of Standards and Technology (NIST) for best practices in maintenance and calibration.

Best Practices for Selecting the Right Industrial Weighing Scale

Choosing the appropriate industrial weighing scale for your business involves several considerations:

- Assess Your Needs: Determine the specific weight capacities, accuracy requirements, and environmental conditions relevant to your operations.

- Evaluate Key Features: Consider factors such as accuracy, durability, capacity, user interface, and customization options.

- Compare Brands and Models: Research and compare different brands and models to find the best fit for your requirements and budget.

- Consider Total Cost of Ownership: Factor in not only the initial purchase price but also the long-term costs associated with maintenance, calibration, and potential repairs.

- Choose Reputable Brands: Opt for brands with a proven track record of performance, reliability, and excellent customer support.

- Invest in Regular Maintenance: Ensure consistent accuracy and longevity of your scales by adhering to regular maintenance and calibration schedules.

Following these best practices will help you select an industrial weighing scale that meets your business needs, enhances operational efficiency, and provides accurate and reliable weight measurements.

Conclusion

Both Rice Lake RoughDeck and PEC Scales offer high-quality industrial weighing solutions, each with its unique strengths. Rice Lake RoughDeck excels in durability and advanced digital filtering technology, making it ideal for heavy-duty and harsh environments. PEC Scales, with their precision load-cell technology and customizable interfaces, provide versatility and adaptability for diverse weighing needs.

Your choice between these two brands should be guided by your specific requirements, budget, and long-term operational considerations. By evaluating factors such as accuracy, durability, capacity, user interface, price, and maintenance, you can make an informed decision that best fits your business needs.

For more information and to explore product options, visit the official ShipScience website.